JoeCrozier

Well-known member

Good morning! Beginner question here:

I've got a few posts on here about how I've been rebuilding an old 144 I got for free, lying in the dirt. Well, I've made a ton of progress and I think its physically 'done', its just time to wire it up, add fuel, and try to start it.

But that little comment about 'wire it up' isnt as easy as it sounds. I'm a total beginner, have no idea what I'm doing, and I've been trying to do everything as cheaply as possible for this little hobby.

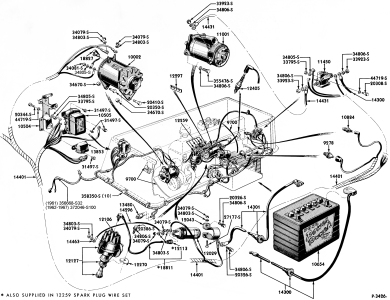

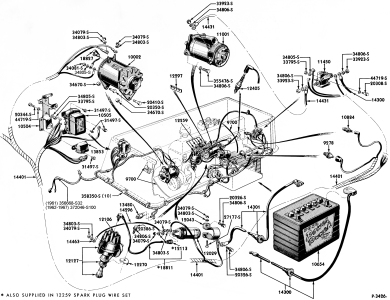

I found a wiring diagram:

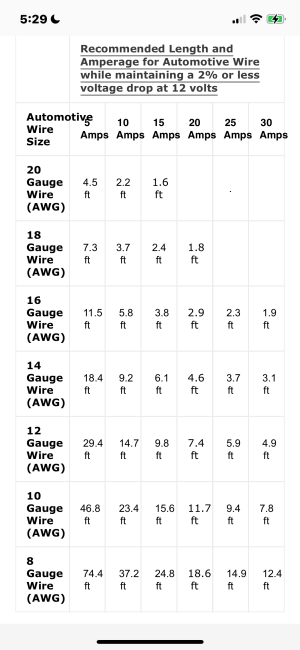

and that's helped, also RockAuto has helped me get things like the starter relay assembly, etc.. but when looking for the actual cables to use I'm kinda at a loss. I dont really care whether things are original or numbers matching, I just want it to work. When I google wires/wiring harnesses for the 144 I get a bunch of old NOS parts that are like $70 for a wiring harness and I'm too cheap to pay that. Are there guidelines for what wires I should use? What gauge? What connectors?

ChatGPT says I can just buy a 4 gauge wire kit kinda like this one and make what I need, but is that true? I don't always trust ChatGPT answers.

Lastly, that diagram doesnt show it, but both the head bolt that I removed and one of the new ARP head bolts that I installed have a little post for connecting a wire to, and I have no idea what its for. Any ideas?

I've got a few posts on here about how I've been rebuilding an old 144 I got for free, lying in the dirt. Well, I've made a ton of progress and I think its physically 'done', its just time to wire it up, add fuel, and try to start it.

But that little comment about 'wire it up' isnt as easy as it sounds. I'm a total beginner, have no idea what I'm doing, and I've been trying to do everything as cheaply as possible for this little hobby.

I found a wiring diagram:

and that's helped, also RockAuto has helped me get things like the starter relay assembly, etc.. but when looking for the actual cables to use I'm kinda at a loss. I dont really care whether things are original or numbers matching, I just want it to work. When I google wires/wiring harnesses for the 144 I get a bunch of old NOS parts that are like $70 for a wiring harness and I'm too cheap to pay that. Are there guidelines for what wires I should use? What gauge? What connectors?

ChatGPT says I can just buy a 4 gauge wire kit kinda like this one and make what I need, but is that true? I don't always trust ChatGPT answers.

Lastly, that diagram doesnt show it, but both the head bolt that I removed and one of the new ARP head bolts that I installed have a little post for connecting a wire to, and I have no idea what its for. Any ideas?