You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How's Your New Head, Mr. Cini?

- Thread starter LaGrasta

- Start date

michael_cini

Well-known member

It sure is purty. But I have many things to get/do before it makes it on the block. I am hoping to be able to install it on the weekend of September 22nd. I have to pick a cam, get lifters and am currently waiting on Mike to get in my Holley carb adapter. I will post pics (probably too many) and all the details when the head is on.

michael_cini":idn1fmxh said:It sure is purty. But I have many things to get/do before it makes it on the block. I am hoping to be able to install it on the weekend of September 22nd. I have to pick a cam, get lifters and am currently waiting on Mike to get in my Holley carb adapter. I will post pics (probably too many) and all the details when the head is on.

Sounds good! C'mon Mike, cough up the parts...

michael_cini

Well-known member

OZ head from bottom ready for new valves.

closeup, opened up for oversized valves.

valves ready for installation.

head with valves and springs installed.

header modified to fit around frame and starter. we had to put a couple of pie shaped cuts/welds to get angle right to clear frame after this. but now it fits!

old head and carb during tear down.

more to come soon.

closeup, opened up for oversized valves.

valves ready for installation.

head with valves and springs installed.

header modified to fit around frame and starter. we had to put a couple of pie shaped cuts/welds to get angle right to clear frame after this. but now it fits!

old head and carb during tear down.

more to come soon.

michael_cini

Well-known member

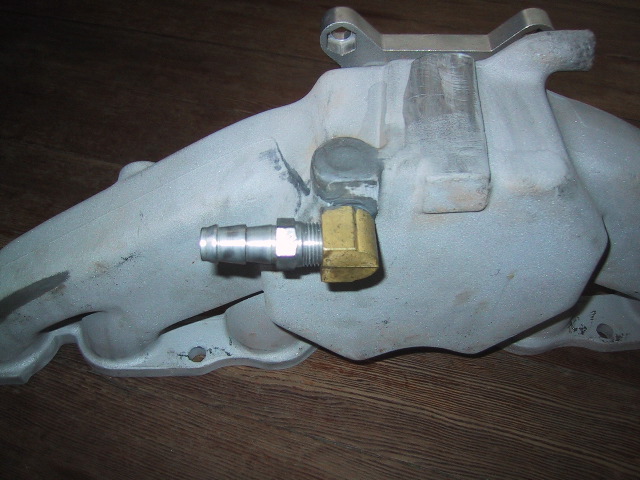

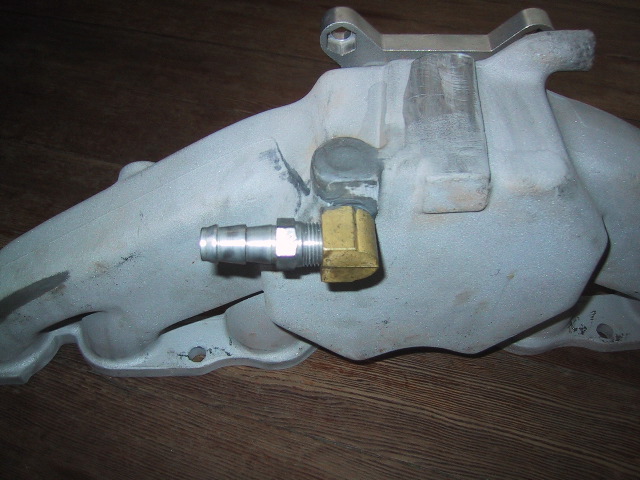

intake water jacket inlet needed to be moved to the bottom to clear the shock tower.

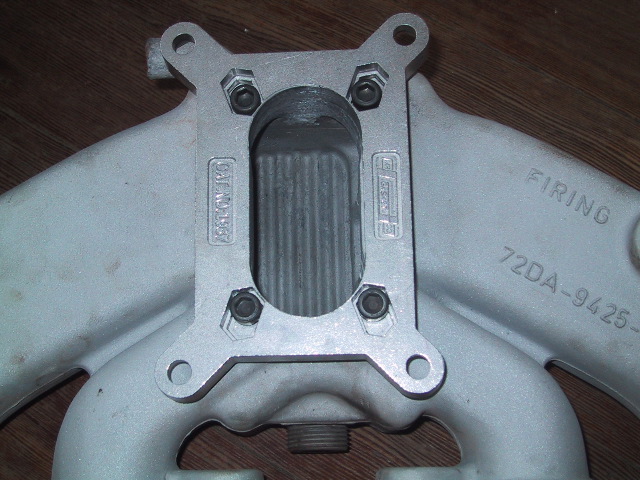

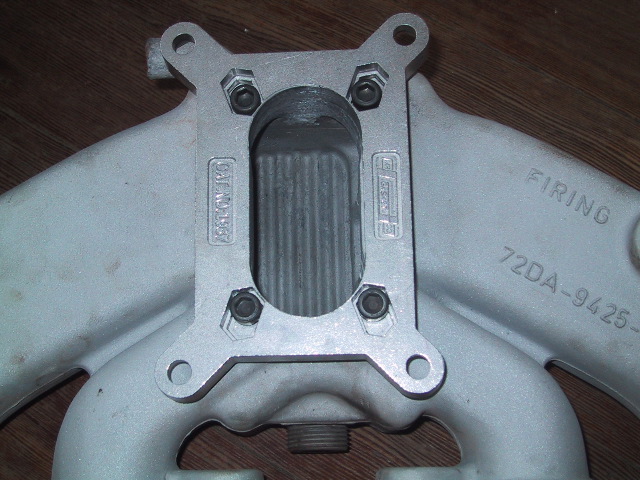

Holley adapter on, hogged out.

head and carb on engine, finally! but we had to pull out the pushrods after this. notice how high the adjusting nuts on the rockers are. the adjusting nuts should be somewhere in the middle of the thread instead they are very close to the bottom of thread. richard my machinist and supreme advisor did not like this angle, he felt with the travel it may even have the rods impacting the bottom of the rockers so we removed them and Richard took the cup ends off of the rods and removed 300ths to shorten them. I reinstalled this evening, they look much better now.

just painted the valve cover to match the intake. it doesn't look too bad, but it could match a bit better to my eye.

Holley adapter on, hogged out.

head and carb on engine, finally! but we had to pull out the pushrods after this. notice how high the adjusting nuts on the rockers are. the adjusting nuts should be somewhere in the middle of the thread instead they are very close to the bottom of thread. richard my machinist and supreme advisor did not like this angle, he felt with the travel it may even have the rods impacting the bottom of the rockers so we removed them and Richard took the cup ends off of the rods and removed 300ths to shorten them. I reinstalled this evening, they look much better now.

just painted the valve cover to match the intake. it doesn't look too bad, but it could match a bit better to my eye.

michael_cini

Well-known member

indeed. initial startup is planned for friday morning. i will keep you posted

LaGrasta":33s3hqos said:ahhh, the 250 beast is stirring. I can't wait to get in and go for a ride. The hammer is soon to be dropped!

michael_cini

Well-known member

yes he did. the cup end is just pressed in, the ball end is welded. so he pulled the cup end out, cut them down, then pressed the cups back in. really not that time intensive.

Bort62":67cwzw1h said:Nice.

You say your machinist removed the cups and shortened the pushrod .03 - did he re-install the cup afterwards (and how - weld?)

Seems labor-intensive. There are pus rods available in nearly any length.

Jett's_Pony

Active member

Forget the push rods, the big question is it ALIVE!!!!

Jett and Jett's Dad

............8)

............8)

Jett and Jett's Dad

michael_cini

Well-known member

Well, I have good news and bad.

First the good, we got it running today. It sounded badass, big and loud without an exhaust. Richard said it sounded like Doc Hudson in the movie cars! It ran for about 15 minutes. Long enough to get the oil flowing and tweak the carb to get it idling decently.

Now the bad news, after it ran for about 10 minutes it started to leak water from what seemed like the back of the engine on the passenger side. We shut it down and tried to figure it out. Richard went home and got his cooling system pressure tool and I jacked the front end up. When he came back we pressurized the system and discovered it was coming from the rear freeze plug on the head. So, then I took off the intake and header, yep the rear freeze plug. I was relieved to know if was the freeze plug and not the head having a crack or something. I was the one who installed the freeze plugs, I guess I pushed them in too far or ??? A couple of others looked a touch wet too.

Anyway, I am tired and feeling rather defeated tonight. I really was hoping I was ready to take 'er to the muffler shop. Anyway, tomorrow I will pull the freeze plugs and get them re-installed. It will be a pain in the ass with the head on the block, but I will get it done.

I'll keep you posted.

Michael

First the good, we got it running today. It sounded badass, big and loud without an exhaust. Richard said it sounded like Doc Hudson in the movie cars! It ran for about 15 minutes. Long enough to get the oil flowing and tweak the carb to get it idling decently.

Now the bad news, after it ran for about 10 minutes it started to leak water from what seemed like the back of the engine on the passenger side. We shut it down and tried to figure it out. Richard went home and got his cooling system pressure tool and I jacked the front end up. When he came back we pressurized the system and discovered it was coming from the rear freeze plug on the head. So, then I took off the intake and header, yep the rear freeze plug. I was relieved to know if was the freeze plug and not the head having a crack or something. I was the one who installed the freeze plugs, I guess I pushed them in too far or ??? A couple of others looked a touch wet too.

Anyway, I am tired and feeling rather defeated tonight. I really was hoping I was ready to take 'er to the muffler shop. Anyway, tomorrow I will pull the freeze plugs and get them re-installed. It will be a pain in the ass with the head on the block, but I will get it done.

I'll keep you posted.

Michael

mach1 mark

Well-known member

Yep, know the feeling on the freeze plug issue. However I was pleased that was the problem, as are you I'm sure. I'm glad its running.

You probably have mentioned this before, but can you remind us. Do you have a C4 or manual, what kind of dizzy are you running.

You probably have mentioned this before, but can you remind us. Do you have a C4 or manual, what kind of dizzy are you running.

michael_cini

Well-known member

mustang6":1isp5ndc said:Did you use sealer on those freeze plugs? I've heard some people say they don't use it but I always have and have never had a leak.

Yes I used sealer, Permatex #2 as someone on this forum had suggested. My friend Richard thinks I pushed them in too far. I got them in using a socket and hammer. Pushed them in a little farther than flush, I don't know. Any suggestions on installation?

mach1 mark":1isp5ndc said:Yep, know the feeling on the freeze plug issue. However I was pleased that was the problem, as are you I'm sure. I'm glad its running.

You probably have mentioned this before, but can you remind us. Do you have a C4 or manual, what kind of dizzy are you running.

Yeah, out of all of the possible reasons for a leak, I was quite pleased to know if was the freeze plugs!

The car has a C4 and I'm running a duraspark distributor.

Bort62":1isp5ndc said:Throw a can of aluma-seal in there when you put the plugs back in.

What is aluma seal?

Leo

Similar threads

- Replies

- 0

- Views

- 362

All Small Six

Export and Monte Carlo braces for VI cylinder head

- Replies

- 11

- Views

- 850

- Replies

- 18

- Views

- 846

- Replies

- 13

- Views

- 988

- Replies

- 5

- Views

- 949