The ITZOLD Mustang project slowly commences.

Is anyone interested in a log headed 6-bbl 3.3 producing a flywheel 200hp and 220 lb-ft?

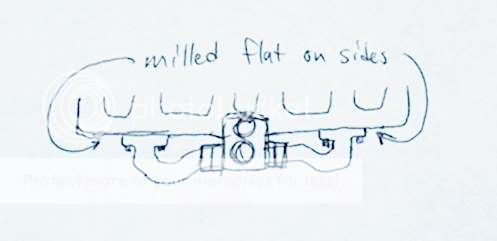

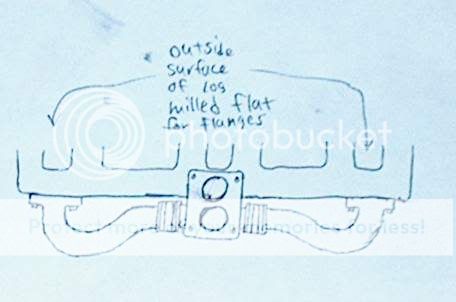

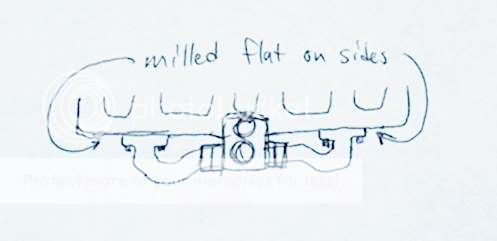

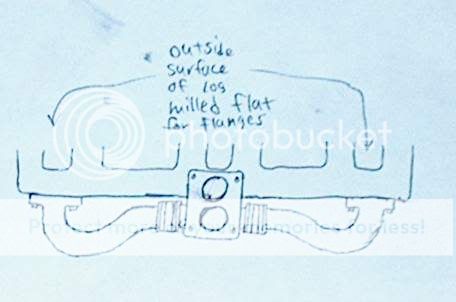

I'm designing a triple Holley 2300 kit based on a multiple throttle body derivation of Linc's 200's ideas

see Multiple TBI's (revisiting)

old link was viewtopic.php?f=51&t=26454&start=0

Basically a 'port on port' independent runner conversion to the log head engine.

Uses carbs like this, in a similar manner, but backwards, facing the firewall for carb linkage access.

Shamelessly raided from the wooden boat forum

http://forum.woodenboat.com/showthread. ... s-restored

Each carb is placed backwards like on this Aussie 13 second nitrous 63 Ford Futura

Been thinking over this one for a l-o-n-g while, so its time to do it.

Although it's just a carb set up for a Log head now, it's calibration and sizing will allow upgrading to triple 350 or 500 cfm carbs to the superior 2V and Classic Inlines head for any 3.3 or 4.1. Longer term, it will allow for a log head to recieve port EFI.

Since I don't have a 2v or CI head yet, I've started on my 82 Mustangs 3.3 engine. It's a 200 6V HO project

1. Based around the 3.3/200 cid engine,

2. Runs three non emisson #7448 2-bbl Holley 2300 series carbs.

-Initially, with the power valve channel restrictions altered

-the venturis honed out to 1.277" from a stock 1 3/16".

3. Air cleaner is stock tri power Cobra/427 element, but its designed to be emissions compliant, so has a tin enclosure allowing stock 5.0 HO 4-BBL dual snorkel and exhast heat stove

4. It has EGR ports.

5. It uses the stock Fox body emissons bits..thermal reactor converter exhast manifold, but altered to suit the Cologne V6 dual cat exhast used in Rangers and Explorers

6. It's ultimately designed to run with a roller cam from a kit I've devised,

7. If I can fund it, be potentially 49 or even 50 states emmisions compliant for 1965-1984 cars. That's based around the premis that I can get the 7448 emissions converted and an approved EO endorsed replacement to the stock 'foot ball' converter B-code Fox bodies ran organised. Cost for individual back to back emission lab acceptance on a stock but altered 82 Mustang is US $27 000.

Ultimately, its block can be US, Argentine or 1970 to 1992 Australian 3.3/4.1 based, use the CI alloy head , and I'm looking at a 300hp 6V HO 250 cubic inch roller cam version.

General reasons for doing this are: As long as there is no emissions increases, a stock 1982 spec 3.3 Mustang with my induction system and a log , 2V or CI head would be an ideal crate engine for any 6 cylinder Mustang, Falcon, Futura/Rancero, early Bronco, Ranger/Fairmont/Granada/Monarch/Cougar/T-bird/Comete/Capri et al. Anything 1984 and earlier would comply. Other reasons are that port on port carburation is a 25% power boost, and that the little I6 is the worlds best economy engine proposition.

Is anyone interested in a log headed 6-bbl 3.3 producing a flywheel 200hp and 220 lb-ft?

I'm designing a triple Holley 2300 kit based on a multiple throttle body derivation of Linc's 200's ideas

see Multiple TBI's (revisiting)

old link was viewtopic.php?f=51&t=26454&start=0

Basically a 'port on port' independent runner conversion to the log head engine.

Uses carbs like this, in a similar manner, but backwards, facing the firewall for carb linkage access.

Shamelessly raided from the wooden boat forum

http://forum.woodenboat.com/showthread. ... s-restored

Each carb is placed backwards like on this Aussie 13 second nitrous 63 Ford Futura

Been thinking over this one for a l-o-n-g while, so its time to do it.

Although it's just a carb set up for a Log head now, it's calibration and sizing will allow upgrading to triple 350 or 500 cfm carbs to the superior 2V and Classic Inlines head for any 3.3 or 4.1. Longer term, it will allow for a log head to recieve port EFI.

Since I don't have a 2v or CI head yet, I've started on my 82 Mustangs 3.3 engine. It's a 200 6V HO project

1. Based around the 3.3/200 cid engine,

2. Runs three non emisson #7448 2-bbl Holley 2300 series carbs.

-Initially, with the power valve channel restrictions altered

-the venturis honed out to 1.277" from a stock 1 3/16".

3. Air cleaner is stock tri power Cobra/427 element, but its designed to be emissions compliant, so has a tin enclosure allowing stock 5.0 HO 4-BBL dual snorkel and exhast heat stove

4. It has EGR ports.

5. It uses the stock Fox body emissons bits..thermal reactor converter exhast manifold, but altered to suit the Cologne V6 dual cat exhast used in Rangers and Explorers

6. It's ultimately designed to run with a roller cam from a kit I've devised,

7. If I can fund it, be potentially 49 or even 50 states emmisions compliant for 1965-1984 cars. That's based around the premis that I can get the 7448 emissions converted and an approved EO endorsed replacement to the stock 'foot ball' converter B-code Fox bodies ran organised. Cost for individual back to back emission lab acceptance on a stock but altered 82 Mustang is US $27 000.

Ultimately, its block can be US, Argentine or 1970 to 1992 Australian 3.3/4.1 based, use the CI alloy head , and I'm looking at a 300hp 6V HO 250 cubic inch roller cam version.

General reasons for doing this are: As long as there is no emissions increases, a stock 1982 spec 3.3 Mustang with my induction system and a log , 2V or CI head would be an ideal crate engine for any 6 cylinder Mustang, Falcon, Futura/Rancero, early Bronco, Ranger/Fairmont/Granada/Monarch/Cougar/T-bird/Comete/Capri et al. Anything 1984 and earlier would comply. Other reasons are that port on port carburation is a 25% power boost, and that the little I6 is the worlds best economy engine proposition.

Thanks for the write up,AND the link to the wooden boat site.AWESOME build on the 430 Lincoln engine.

Thanks for the write up,AND the link to the wooden boat site.AWESOME build on the 430 Lincoln engine.