A

Anonymous

Guest

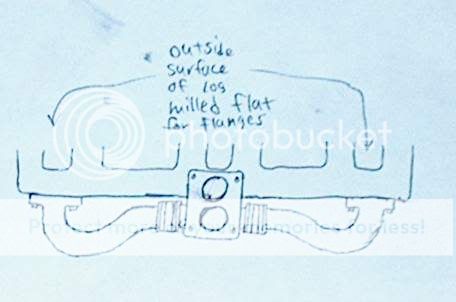

I have been studying the two barrel log Linc's had drawn up. The challenge I see is fabbing up and fitting a plenum for the secondary venturi to the outside runners. Sorry I don't know how to copy that pic. Maybe Linc's could post it.

The problem addressed is the dead ends at 1 & 6. By feeding these with that second "log" you would have a better charge.

What if the plugs on the ends of the log were opened to match the rest of the runner, and a 270 degree tube run to an opening between 5&6 and 1&2. I don't know how to put up a drawing. This would loop the charge around instead of slamming into the plugs at the ends. I can't begin to understand all the flow dynamics involved here, but on the surface it seems to make sense.

The problem addressed is the dead ends at 1 & 6. By feeding these with that second "log" you would have a better charge.

What if the plugs on the ends of the log were opened to match the rest of the runner, and a 270 degree tube run to an opening between 5&6 and 1&2. I don't know how to put up a drawing. This would loop the charge around instead of slamming into the plugs at the ends. I can't begin to understand all the flow dynamics involved here, but on the surface it seems to make sense.

:nono:

:nono:  :smash:

:smash: