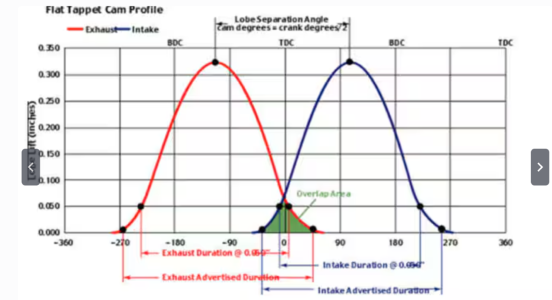

LSA discussions are new to me so I've been doing some research. At this time this is an academic exercise that will let me better understand some of tradeoff decisions when building my engine. Though there are lots of discussions with LSA included I was hoping to have more of an broad theory discussion relative to the 300 but not specific to engine build goals (high rpm, low rpm, turbo etc.) Then again if someone has a link they really like I'd love to read it. And if I missed a post during my search please let me know.

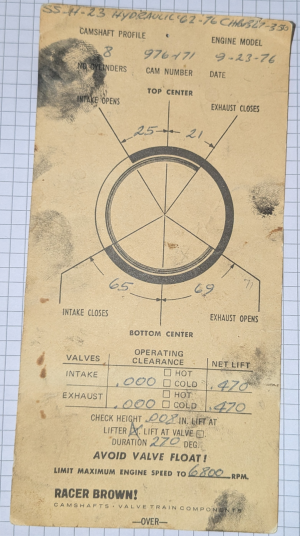

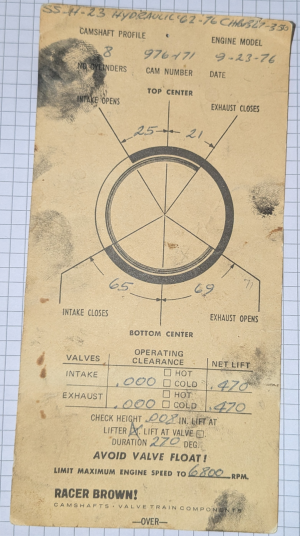

My baseline for this discussion is one of my early builds that used the cam below (just for fun). This was in a 350 Chevy and resulted in an engine with a nice lope at idle and nearly instant torque off idle as measured by my calibrated butt dyno. I was a fun street engine.

Looking at the cam card above I believe that the LSA was 112 degrees (on the "wide" side by internet standards). Are my calculations correct? Would this cam profile in a 300 have a similar effect?

Also I'm a little confused (the internet does that) so can we discuss LSA and specifically how it impacts a 300 engine build? Some of the items that I read go a little counter to what I understood. Other issues are just not understood. So in no particular order:

Sorry for the long post but this is now becoming interesting to me.

Bart

My baseline for this discussion is one of my early builds that used the cam below (just for fun). This was in a 350 Chevy and resulted in an engine with a nice lope at idle and nearly instant torque off idle as measured by my calibrated butt dyno. I was a fun street engine.

Looking at the cam card above I believe that the LSA was 112 degrees (on the "wide" side by internet standards). Are my calculations correct? Would this cam profile in a 300 have a similar effect?

Also I'm a little confused (the internet does that) so can we discuss LSA and specifically how it impacts a 300 engine build? Some of the items that I read go a little counter to what I understood. Other issues are just not understood. So in no particular order:

- A tight LSA helps the low/midrange torque but can create a rough idle condition. Accurate or oversimplified?

- I always equated a rough idle to a cam that targeted power in higher RPMs. Something is going on here beyond just LSA I'm sure. Clarification?

- A tight LSA creates a "narrow power band". This doesn't feel accurate, thoughts?

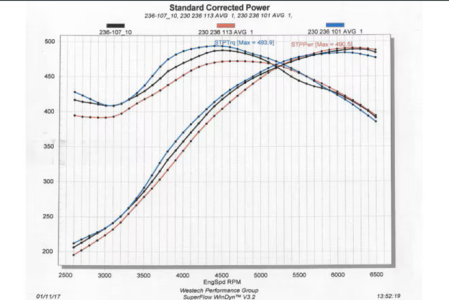

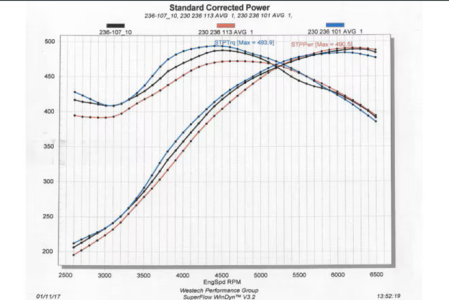

- The graph below is the result of testing a cam with different LSA's. The tightest LSA created torque and horsepower curves with the greatest area under the curves which, to me, implies a wide power band. Ok I understand that across an rpm range is probably a more common view of power band but….. Thoughts?

- The chart and comment are from this article, https://www.hotrod.com/how-to/camshaft-shootout-lobe-separation-angle-tested-explained/

- It feels like overlap amount and overlap timing should be discussed more when talking about LSA. Am I missing something here? For instance in the model above cylinder pressure was highest with the tightest LSA but isn't the reality more of a function of valve timing. In other words by changing the timing of the events couldn't the cylinder pressure have been maintained even though the LSA's changed?

- Other LSA "impacts" that should be understood?

- Finally, for a 300, what is considered a tight/wide LSA?

Sorry for the long post but this is now becoming interesting to me.

Bart