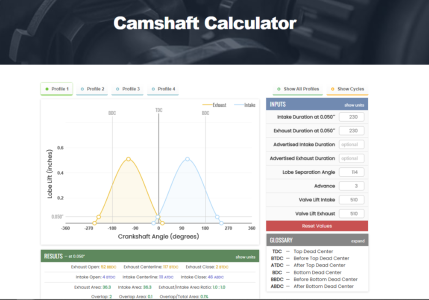

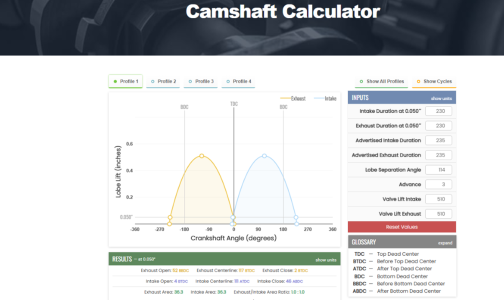

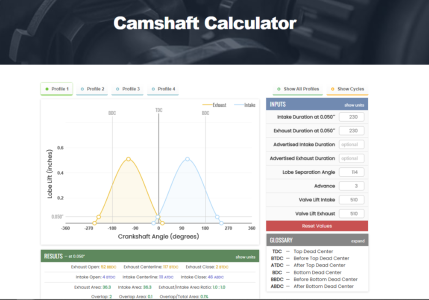

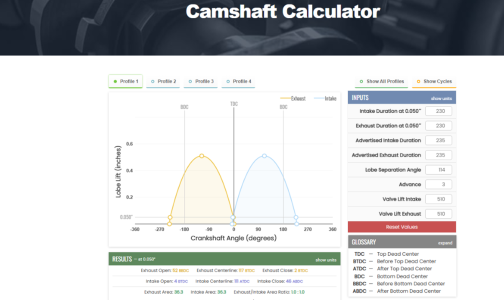

Testing my understanding. The program I'm using is https://mgispeedware.com/camshaft-calculator/. It doesn't differentiate between cam type when it builds a model. I'm just playing with my understanding of a roller vs flat tappet cam profile with similar specs and LSA's. The one on the right is my attempt to create a roller cam profile (using the advertised duration). Am I on the right track?