I like the idea of this ' no weld' version.

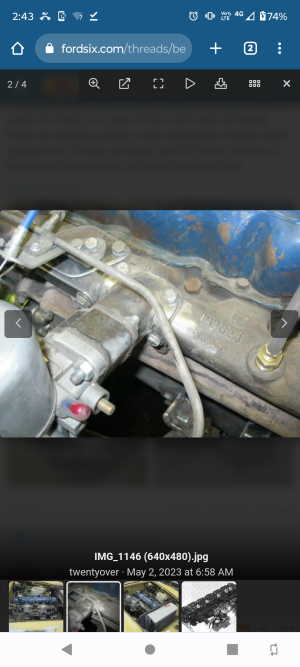

Twin side draft SU carbs with inlets stubs with plate formed to the log outline and some tapped bolts and gaskets to hold it all together.

Looks like a six in an MGB

View attachment 24323View attachment 24324

my 66 volvo 122 had those stock, dual HS-6 SU's. were used on the 1800 and 2 litre. the 300 could probably run three of them quite nicely. I think a lot of british cars used them too. you can get different jet sizes,, I went with the ones that came with a 2 litre. bored mine from 1800 to 2 litres. they work nice, very reliable anyway. the atomization might be different or better with other carbs. the 4.9 litre is a lot higher displacement-wise but the max revs are a lot lower so I guess that is part of the full throttle, flow equations.

there is no choke plate, , instead the choke lowers the bottom hole of the jet letting more fuel through, simple. the little damper pots take a little ATF and that stops the cylindrical part which is joined to the jet from moving too suddenly and causing jerkiness or a stall. as air goes through it lifts the cylinder up lifting the jet and opening up the fuel flow. no accellerator pump. with the air cleaners off you can see it move as you give it throttle, and they should be synchronized. with 3 you'd have a bit more to do to syncronize all 3 to get the right fuel mix but it probably wouldn't be too hard. one could probably keep the same throttle shaft setup, but with some mods.. I put new bushings and throttle shafts and jets in mine and its run flawlessly for some 25 years. no adjustments.

I think as they moved forward there were other larger versions in 70's with their early 240's and I believe some of those had single SU's .. until FI took over. some of those larger carbs , I think had diaphrams, and getting new diaphrams may have been a problem? this one , the HS6 was simple, it had none of that. I might be a bit swayed towards them just because I'm familiar .

my brother got fed up wiht ECU issues and converted three 240's from FI to carbs, removing all the complicated electronics in the process, they had less power but better reliability.. that was his basic goal, not performance, just simplicity. It did work.

like the ford since there were at one time carb models its basically a matter of using a few of the older parts and you can dumb it down , increasing reliability..

FI was an imporovement, more power, better mileage, but it brought with it a lot of complexity and not really huge gains ..more relays and wiring complexity. for their expected lifetime they were still quite reliable. My interest in them faded as the complexity increased into the 90's

The manifold is coming along nicely... It looks fun.