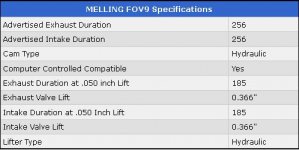

The large log ENGINETECH ES658 + MELLING FOV9 cams are both 256 .366" lift. Early small log cams were around 246 at .350" lift

Higher lift aftermarket cams will have a smaller base circle which will lower the lifters in their bores. I think the smaller base circle would increase the chance of a lobe going flat.

My 200 with an ENGINETECH ES658 will wind to 5,300+ in low. I usually do WOT shifts at 5,000.

RockAuto ships auto parts and body parts from over 300 manufacturers to customers' doors worldwide, all at warehouse prices. Easy to use parts catalog.

www.rockauto.com

View attachment 19410