You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Offy with steinjager

- Thread starter mluck

- Start date

mluck":10wfw3lz said:I see there is a linkage set up for the offy setup call steinjager for the 68 mustangs....why won’t it work with a 67 ..

Because of a whole range of Federal and California emissions upgrades, it was decided by Fords powerplant engineers that the Falcon based Mustang would became a Big Block 390/427 and 250 in line six capable chassis which would be air conditioned with power steering and power brakes.

Hence five things were different on the 1968 verses the 1967 Mustang. These were executive decisions that Lee Iacocca and the team didn't have much control over. A compact Mustang suddenly became a heavier intermediate, and 1968 pushed a whole bunch of very significant changes.

So five things changed.

1. Ignition

2. Carb vacuum advance

3. C4 or FMX or C6 Kickdown Operation

4. chassis width

5. Accelerator operation.

The accelerator linkage changed for C4 Green Dot down shift and the actual operation of accelerator in 1968 changed when the Falcon six in the Mustang became Autolite vacuum advance rather than Load-o-matic.

By 1969, it was cable operated, and by 1970, it was progressing to either YF Carter or Autolite 1101 or, eventually, the Carter RBS carb.

The Offenhauser linkage form 5205 triple Holley's , Autolite or Weber 34 ICT/ICN combinations never worked properly.

The 1969 Mustang cable linkage does, but you have to do a lot of upgrading work to get it to work smoothly.

viewtopic.php?f=1&t=77043&p=592939#p592939

Varilux":10wfw3lz said:One of the frustrating quirks of my 3x1 Offy set up has been the tendency of the linkage to "stick" from time to time- especially after the engine is hot, resulting in the throttle sticking open. Unsticking it required some rather violent stabs at the accelerator pedal. A few months ago, I finally identified the culprit- the metal connecting rods and the guides they slide through.

When cold they slide easily, but as they heat up they stick. I suspect this is because they sit right above my header. Also, the guides have sharp edges on the holes, which creates nicks on the rods- which causes them to stick even more. I've wanted to chamfer those guides and increase the diameter of the guide holes- but didn't want to risk messing up my linkage (since I have no spare parts, and didn't want to purchase another whole kit just to get some new guides).

Anyway, I finally found Offenhauser's website- offenhauser.co (.co not .com) and spoke to one of their staff about purchasing some spare parts. He referred me to their distributor- offyparts.com. The guy there was very helpful and sold me new connecting rods and guides (they call them "buttons") for $42 delivered. Armed with "spares," I increased the size of the hole in the guides (the diameter of the holes are 3/16" from Offy) to 7/32". Then I used a 3/4" chamfering bit (followed by a beveled grinder bit to smooth) to take off the sharp edges. Bingo! I went for a spirited drive in 100+ degree weather over the weekend and absolutely NO sticking! In fact, the accelerator functions far more smoothly.

Now I need to find a solution to overheated fuel. After one of my stops, it was a bit hard to get started, and it ran rough for a few minutes. I saw another thread that suggested aluminum clothespins on the fuel line to dissipate the heat- will try that.

posting.php?mode=quote&f=1&p=589492

Varilux":10wfw3lz said:How about some more pictures of the engine- especially the linkage. Thanks, in advance.

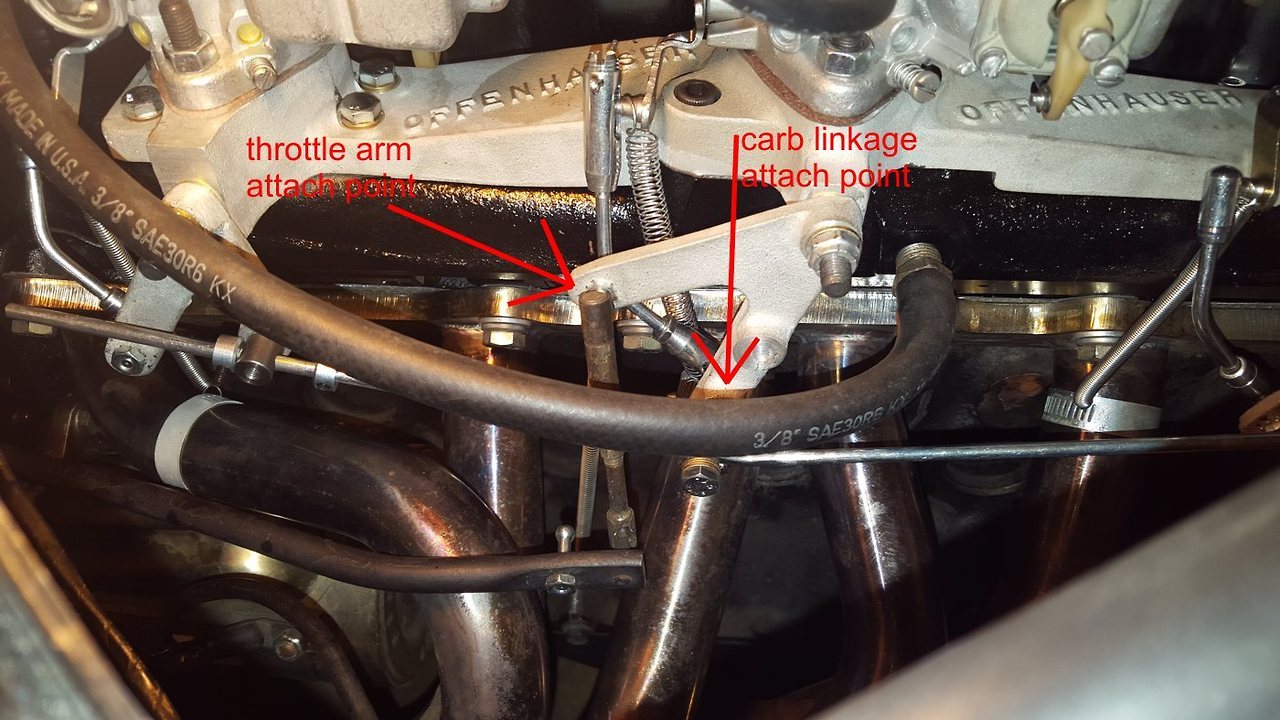

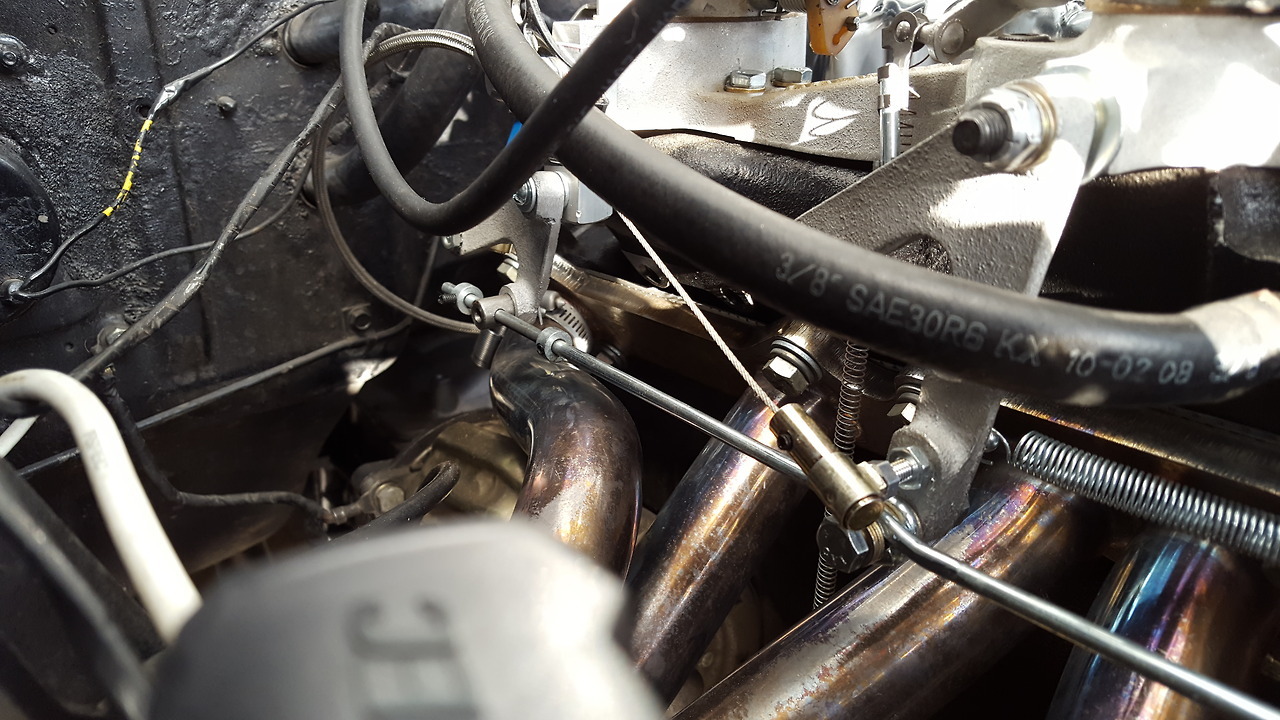

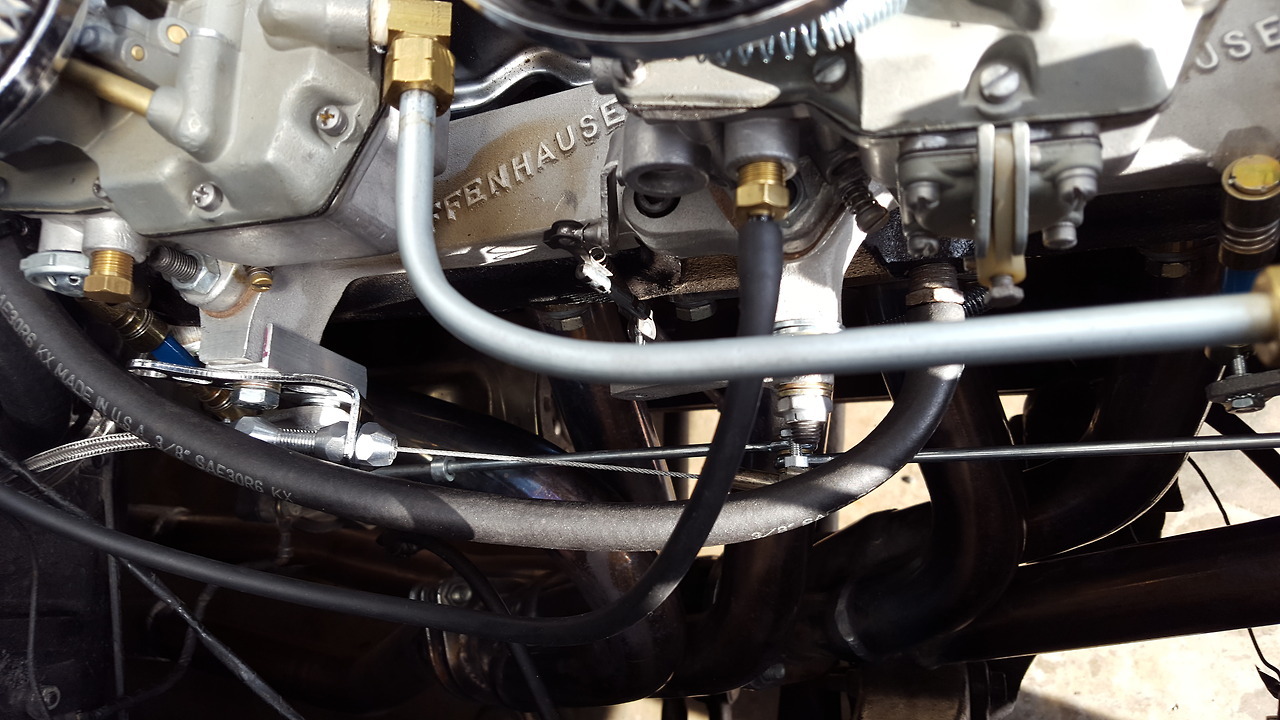

More than happy to post pics of the linkage- heaven knows it is embossed on my brain. It took all of a couple hours to install the head and hook up the fuel supply lines, but I've easily spent 80+ hours fiddling with the linkage to get it just right.

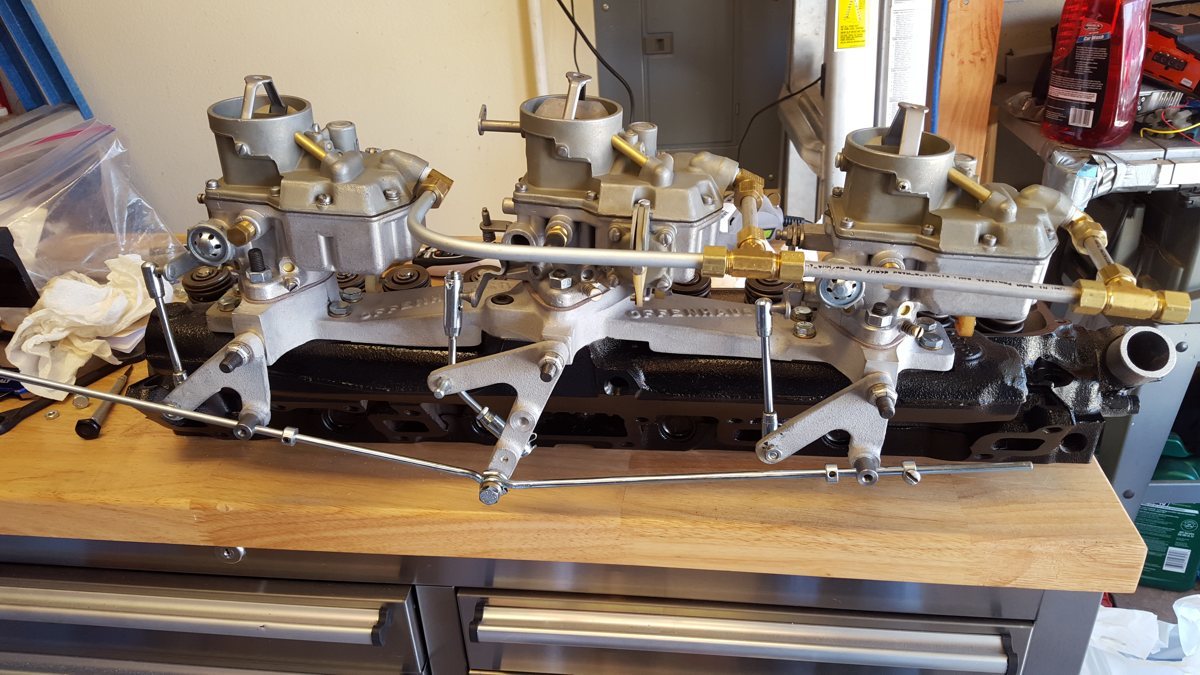

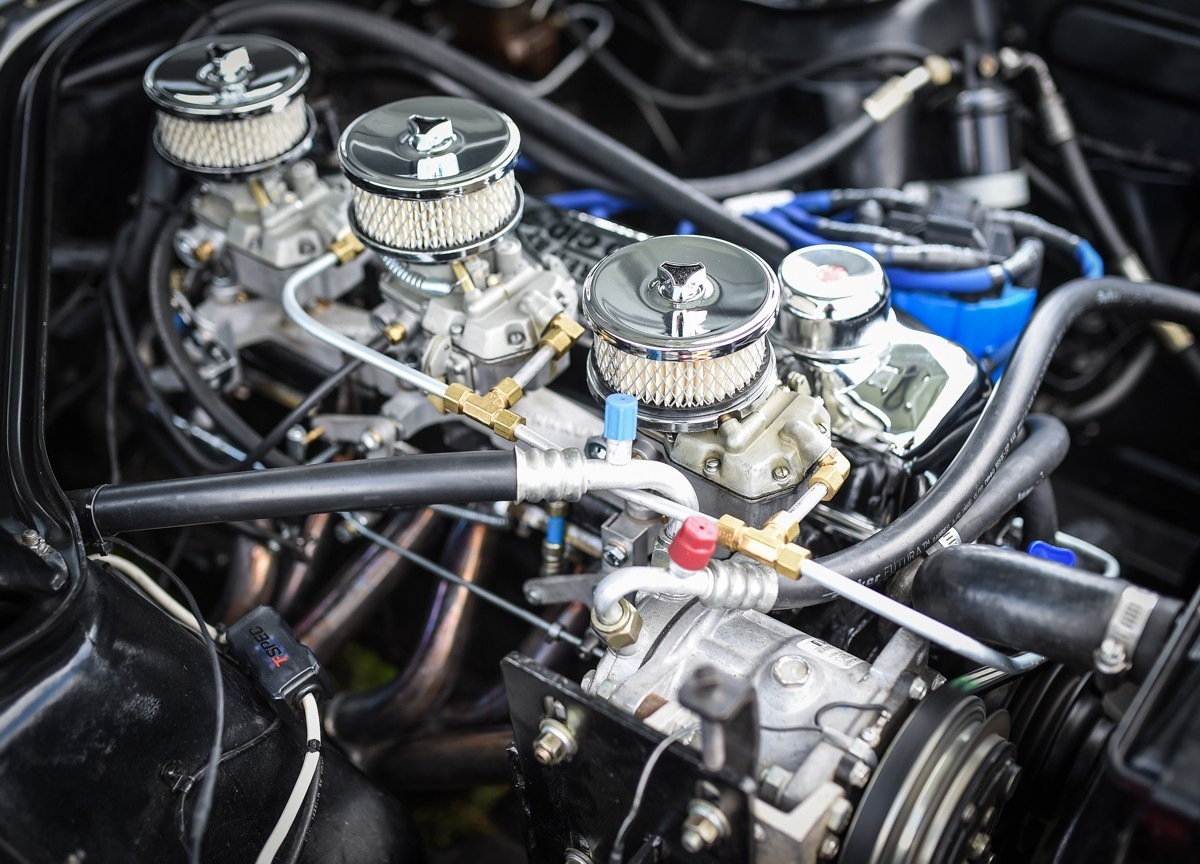

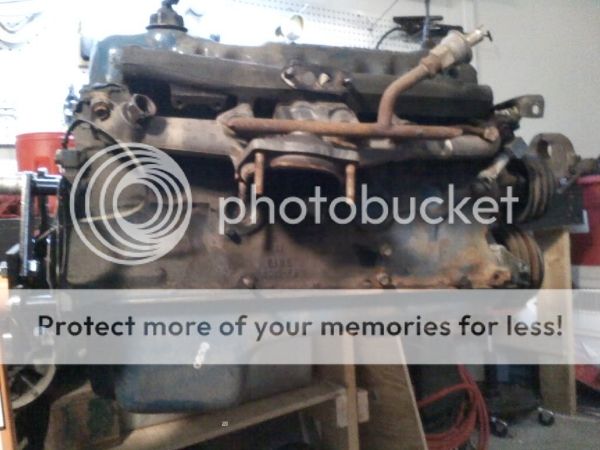

Here is the Offy setup plumbed and sitting on the bench (ah the innocence of that moment- little did I know the hours of frustration that were about to occur). In fact, I couldn't even lower the head onto the engine at first (because the front carb's fuel line caught on the A/C hoses).

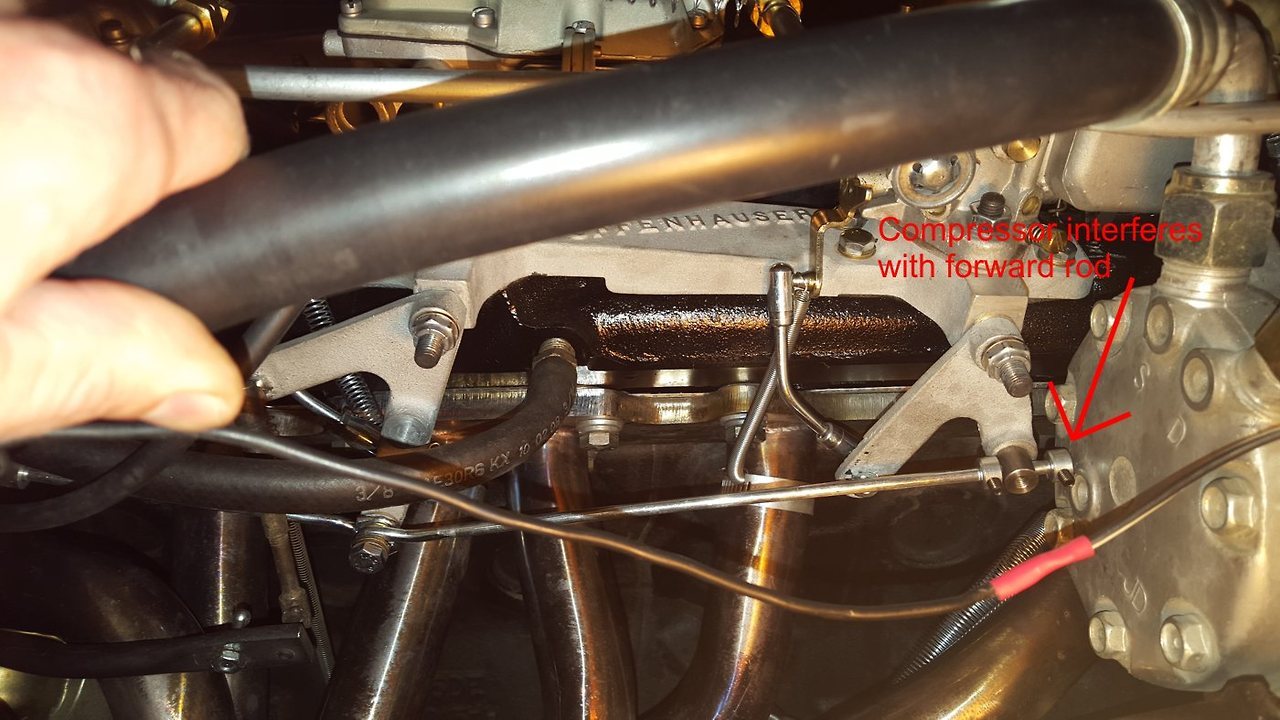

Issue #2 was also immediately evident. The front carb rod was unable to travel far enough forward due to the A/C compressor. Given that I do not have power steering, I would LOVE to figure out how to relocate the A/C compressor to the driver's side of the engine. It has been a constant challenge (e.g., had to adjust the mount to install the header). Solving the problem involved shortening the front rod of the Offy and relocating the compressor forward (there are two "Vs" on the pulley, so I went from using the front to the back- happily, this also solved a squealing issue I had).

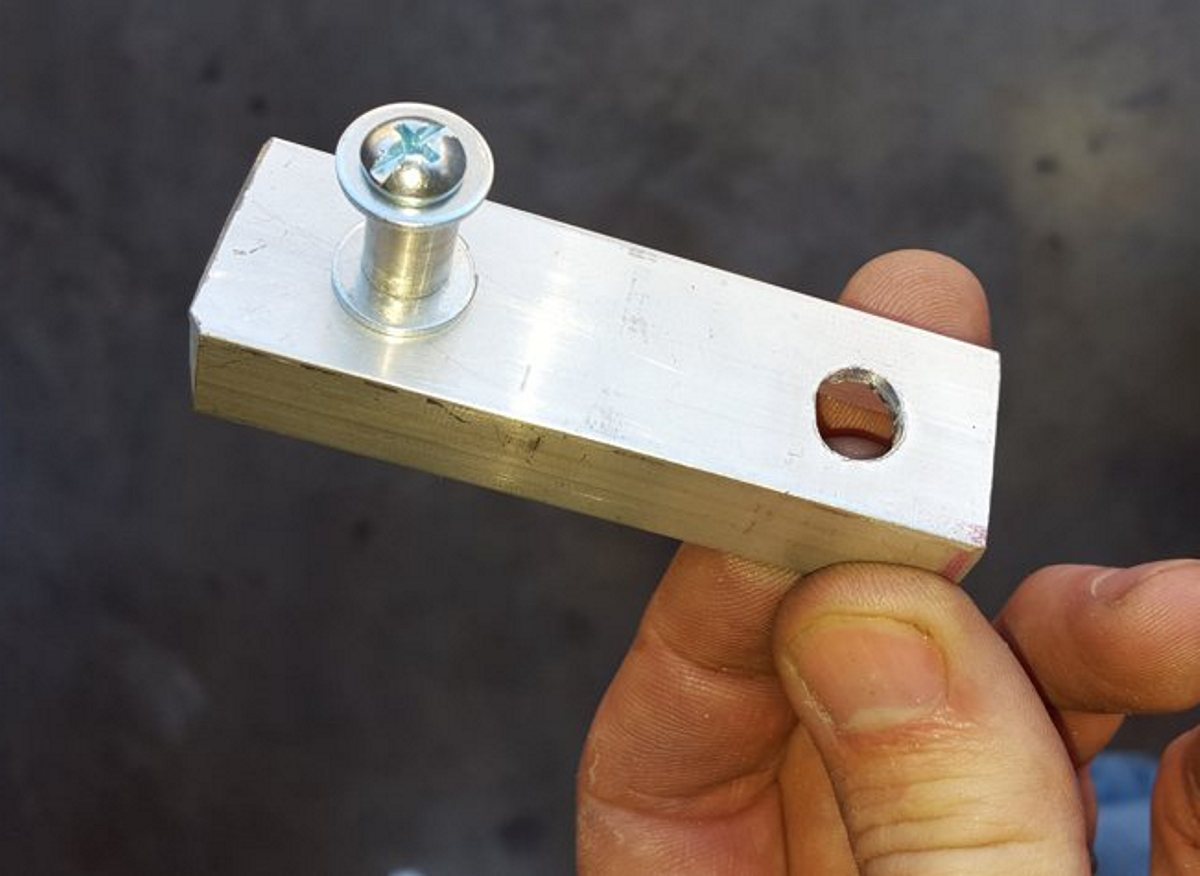

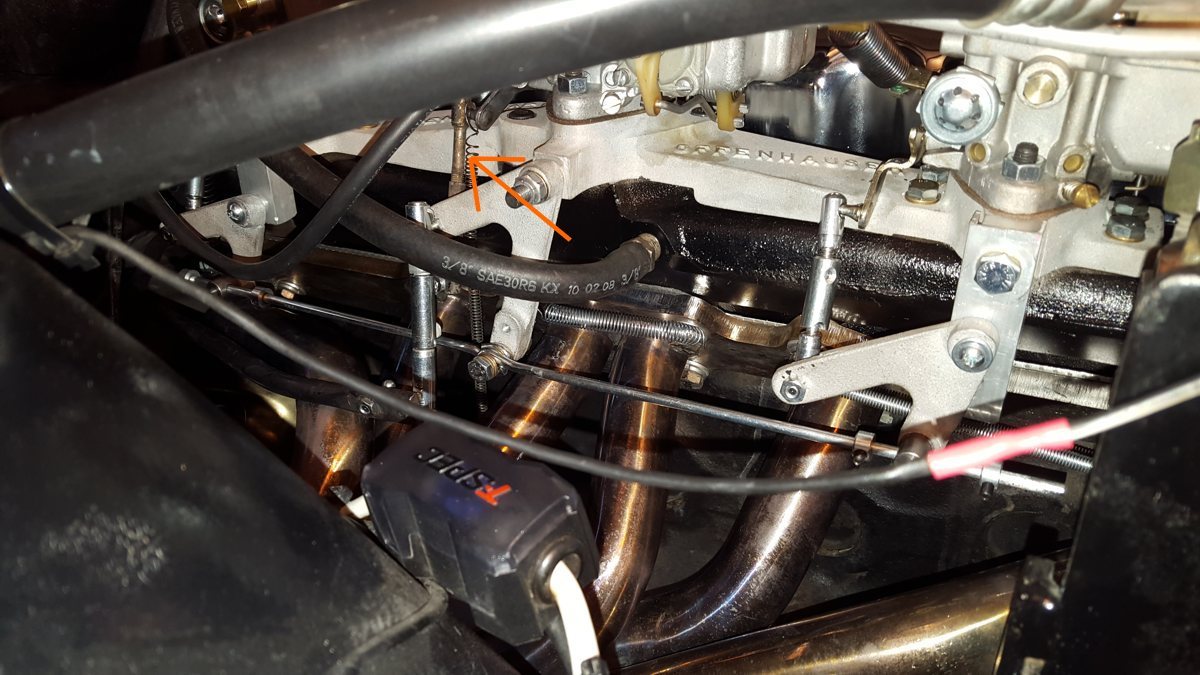

The next issue had to do with the angle the carb rods were held at. The kit caused a "V" pattern to the rods, which just didn't seem to work, plus it would have required carb linkage rods that would be <1" long (completely impractical). After some thinking, this was easily solved with some aluminum "U channel" from Lowes (its back where they have the metal rods and metal bars). The U fits perfectly over the rectangular pivot mount on the Offy adapter, and- with a couple of holes- you can put the pivots at whatever height you like. The linkage rods still needed to be exceptionally short, so I created them from the components shown in the last picture.

At this point, I had things basically "working," but driving the car was VERY frustrating. The throttle activation bar (that long bar that goes from the gas pedal to the center linkage) just had to go for several reasons. First, the header interfered with the bar (it could not travel down far enough to allow the center carb to return to idle). With a single carb this wasn't a problem because I could adjust the linkage rod shorter, but with the Offy, the center linkage rod was already as short as it was going to go. The second issue is the extra return springs for the three carbs created an issue where the bar would try to "deflect" towards the passenger shock tower rather than push the throttle up. Finally, as the throttle was engaged, the bar would occupy the same space as the center carb's pivot. After messing with it for months, I finally decided to bite the bullet and convert to a cable throttle. I purchased a '69 gas pedal, drilled a few holes to relocate the pedal mount, and yes- this was definitely a better solution. Additionally, the mount for the rear carb's pivot (the U piece I had fabbed earlier) provided the PERFECT mount for the end of the cable. For the first time, I was really really glad I had installed the 3x1. If I could go back and change any part of the process, I would have converted to the cable throttle as I was swapping the head. It would have probably cut at least 75% of the time from this project.

And that brings us to current status. The drive is just great- at about 60% throttle, you feel the resistance on the pedal increase and- assuming you push through it- you get pushed back in your seat as the secondary carbs kick in. The only remaining issues are the front carb slider keeps hanging up once the car is hot (really frustrating, because the idle will hang up at 2000 RPMs and you have to goose it to get it to kick down). I noticed there is a bit of some sticky stuff on the rod, but I think I need to take the "slider" (the part attached to the pivot that glides on the rod) off and smooth out the entrance holes a bit. The other thing is I cannot find a center throttle rod that is short enough (so I have fabbed one with some bar and clips- but I don't like the appearance of the clips and am worried they could pop off). I ordered a Ford tractor linkage that is 2.25", and it is so cloooose, but it really needs to be 2.00" in length. One of these days, I'm going to see if a shop can cut the center, and reweld it together.

I am a rank amateur in the garage, so if you have ANY kind of mechanical prowess, you can easily do this project (and probably spend a lot less time doing it than it has taken me). As mentioned before, simply adding three carbs really changes the whole show experience. Just pop the hood up, and wait for people to start seeking you out to ask questions and make comments!

The 67 linkage is rod operated while the 1969 is cable.

In my opinion, the 1968 wasn't a successful transition year...the engine and frames mounts were similar to 1967, but lots of work on the six cylinder stuff was being done because Ford couldn't get many small block 289 or 302 V8's that year.

For 68 model year, a lot of 200 and 390 engines were sold in 1968 to make up for the factory strikes and Windsor, Cleveland and Lima engine plant supply problems as the production lines were being refitted for 351 Windsor and 351 Cleveland's and 429/460 Limas. The 200 and FE 390/427s came from the other Cleveland plant.

The 69 Mustang linkage was what the 1970-1978 Maverick, 1978-1983 Fox frame and 1973-1986 F-truck in line six vehicles started perfecting during the 70's. Its what Lockar copies and sells today.

The rod operated 67 verses cable operated 69 details from Vintage Mustang forum.

The 1967 was rod operated everything, and if automatic, its a complicated rat trap system of parts.

In my opinion, the 1968 wasn't a successful transition year...the engine and frames mounts were similar to 1967, but lots of work on the six cylinder stuff was being done because Ford couldn't get many small block 289 or 302 V8's that year.

For 68 model year, a lot of 200 and 390 engines were sold in 1968 to make up for the factory strikes and Windsor, Cleveland and Lima engine plant supply problems as the production lines were being refitted for 351 Windsor and 351 Cleveland's and 429/460 Limas. The 200 and FE 390/427s came from the other Cleveland plant.

The 69 Mustang linkage was what the 1970-1978 Maverick, 1978-1983 Fox frame and 1973-1986 F-truck in line six vehicles started perfecting during the 70's. Its what Lockar copies and sells today.

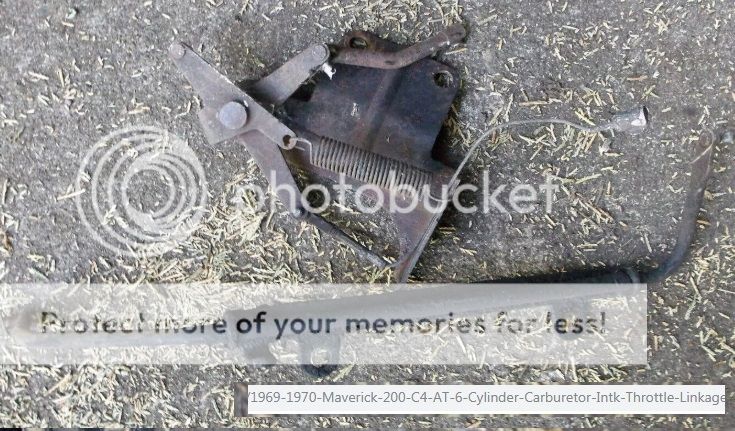

xctasy":1y4n3kjo said:The throttle linkage and kickdown rod on early 69-70 Ford small sixes with the 250 carb before the RBS had the 9728 bracket as a throttle bracket.

When EGR was introduced, the whole actuation changed, but the part continued to be mounted to the same two bolts at the rear exhaust manifold plane of the head.

Note the following

I'm certain there are high resolution pictures of bracket BPN 9728.

Just can't find em.

1969-1983 200/3.3 or 1969-1980 250/4.1 is whacha whacha whachawant...

Every C9 onwards head till E0 had the two bolt hole boss cast into the back part of the head, some early ones weren't drilled.

from http://www.fomoco.org/tech-tips/how-to- ... t-numbers/

BPN

9500-9599 is the Carburetor

9700-9999 = Accelerator and choke control rods

As of the advent of the C5 and AOD, it went to a cable linkage on the YFA Big Sixes, but the 1969-1970-1/2 Falcon, 69-73 250 Mustang, 69-77 Comete/Maverick/1975-1983 Granada/1975-1980 Monarch/1979-1982 Mustang/Capri/ 1978-1983 Fairmont/Zephyr all used a rod operated version.

The internal BPN number will most likely be #9728

the 6 cylinder 240/300 F-Truck and E-Van system.

It should be under the Ford Six Performance old Classic in lines tech articles

Its not under 1bad6t.coms 170/200/250 69-77 Maverick rod operated kickdown linkages.

They were under this link

03-12-2012, 03:26 PM #1 by pd59

https://www.ford-trucks.com/forums/1146 ... s-etc.html

Both the Big Six and Small six rod operated kickdown bracket were similar, but not 100% the same.

The #9728 C4 and C5 kickdown rod bracket on the 1978 to 1985 non feedback carb F100/150'S has a similar mushroom on the rod as the stock Small Six 1969-1983 rod operated kickdown.

Gary's Garagemahal (the Bullnose bible) is still active.

http://www.garysgaragemahal.com/kickdown-linkage.html

7A185 Rod operated for Duraspark equipped Feedback MCU and non feedback non computerized 4.9 liter truck and Van YFA Carter

for FMX/C6/C5/C4 on the 4.9 big six.

"http://www.garysgaragemahal.com/uploads/6/5/8/7/65879365/300-six-linkage-illustration_orig.jpg"

The 1983-1986 cable operated bracket is #9728, and near the 57632-S (U-10-A) picture for later TFi equiped EECOV 4.9 liter truck and Van YFA Carter, for AOD 4speed autos.

"http://www.garysgaragemahal.com/uploads/6/5/8/7/65879365/aot-300-six-linkage_orig.jpg"

The rod operated 67 verses cable operated 69 details from Vintage Mustang forum.

The 1967 was rod operated everything, and if automatic, its a complicated rat trap system of parts.

I had many Mustangs over the years form 1965 to 1968 and worked on many other people cars too. A quite few of mine were1967 Mustangs including one GT 390 FE (first year FE engine was offered in a Mustang) with 4 sped plus a couple 68's I saw little differance in the chassis and body size to me 1967 was the major year for change in widening the chassis from the small Mustang chassis used in the 1964 1/2 to 1966 Mustangs. Most parts without major work should should be able to be fitted into a 1967 chassis

True over the basic chassis:-

but for 68 everything was additionally beefed up and either IMCO or Thermactor equiped, with the vacuum tree and the part references and C7 casting suffix changed, with a uniform 5 hp loss of power on each engine except the 390; the mid year 68 inclusion of the 155 hp 250, the 2bbl 220 hp 302, Shelby 230 hp J code 4bbl, dual quad 240 Hp Q code 302, 335 hp 428 CJ were all due to new ignition and emissions packages, 17 power teams with standard thermactor and its needed ignition and casting changes as opposed to just 13 in 1967.

The 50 states Federal Emissions means no water heated six cylinder head intake adaptor, and either 49 states IMCO or CA 50 th State, each with a casting and linkage change on the now 115 hp six.

See

/viewtopic.php?t=19757&highlight=vacuum+switch

And the Edlebrock F360, Offy 5017/5205/5970 linkage Never worked on the Offenhauser 5205...it had no part number change for 68 but there are custom suffix casting changes before the 5970 Offy D0 to E1 head. So lots of part number variances which stop the already defective 1967 era Offenhauser linkage working.

Not down on the Offy; it just needed the Cobra6 and Varilux improvements.

but for 68 everything was additionally beefed up and either IMCO or Thermactor equiped, with the vacuum tree and the part references and C7 casting suffix changed, with a uniform 5 hp loss of power on each engine except the 390; the mid year 68 inclusion of the 155 hp 250, the 2bbl 220 hp 302, Shelby 230 hp J code 4bbl, dual quad 240 Hp Q code 302, 335 hp 428 CJ were all due to new ignition and emissions packages, 17 power teams with standard thermactor and its needed ignition and casting changes as opposed to just 13 in 1967.

The 50 states Federal Emissions means no water heated six cylinder head intake adaptor, and either 49 states IMCO or CA 50 th State, each with a casting and linkage change on the now 115 hp six.

See

/viewtopic.php?t=19757&highlight=vacuum+switch

And the Edlebrock F360, Offy 5017/5205/5970 linkage Never worked on the Offenhauser 5205...it had no part number change for 68 but there are custom suffix casting changes before the 5970 Offy D0 to E1 head. So lots of part number variances which stop the already defective 1967 era Offenhauser linkage working.

Not down on the Offy; it just needed the Cobra6 and Varilux improvements.

As far as the 1968 428 CJ Mustangs there were very few built (I think about 100 at first) mostly for the Drag Race Super Stock class I got see those run at the 1968 Winter Nationals.

I have not had the chance to compare all the Offy intake numbers side by side or the different linkages so your are probally right. Best of luck

I did call steinjager...they said the reason they said 68 mustang only was because they tested it on a 68 and really had no idea 67 where basically the same car..after a schooling on fords with the offy...he agreed that it should fit all early mustangs along with falcons.so thanks for your help.

Mluck, since your car is in Minnesota and now has Mallory mechanical advance Unitlite Hyfire and Triple Webers then the issues are moot ones as Bubba said. Hope you get the linkages on your 67 working good.

Do consider the cable upgrade. Cobra6 found the Offy linkage a great device for keeping out of the secondary outer carbs. Very heavy. Varilux nailed the problem by...mmmm ...luck!

...luck!

Do consider the cable upgrade. Cobra6 found the Offy linkage a great device for keeping out of the secondary outer carbs. Very heavy. Varilux nailed the problem by...mmmm

Similar threads

- Replies

- 17

- Views

- 1K

- Replies

- 11

- Views

- 797

- Replies

- 2

- Views

- 486

- Replies

- 2

- Views

- 213