FALCONAROUND

Well-known member

How much power can a stock 200 rod take?

Are there any stronger alternatives when one want's to turn 7500+ rpm's?

Are there any stronger alternatives when one want's to turn 7500+ rpm's?

FALCONAROUND":3f4q3i1s said:I want to erods to compliment the friggin 7 bearing crank...

My original log head will flow BETTER than any of you can imagine.

I am designing the carb stack myself and porting the head and taking in larger valves too... 1.499 dia exhaust and as large as I can get on the intake.

I am porting the complete log not just cutting holes in it like a schoolboy doing an Offy log....

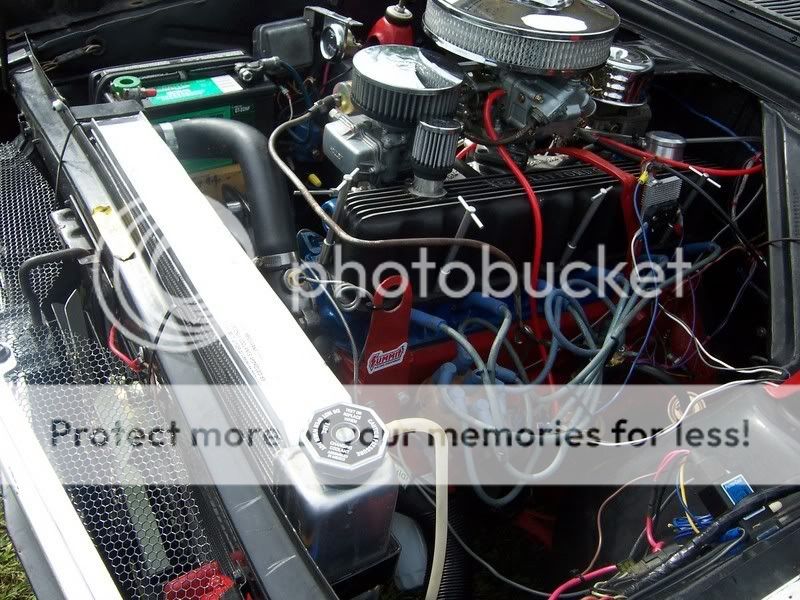

I'll post pictures.

FE

How much power can a stock 200 rod take?

Are there any stronger alternatives when one want's to turn 7500+ rpm's?