canvaspaul

Well-known member

Hello guy's

I bought a small block with automatic transmission. The same engine i have in my mustang.

Like to bring it back to live, but stumble on a few problems.

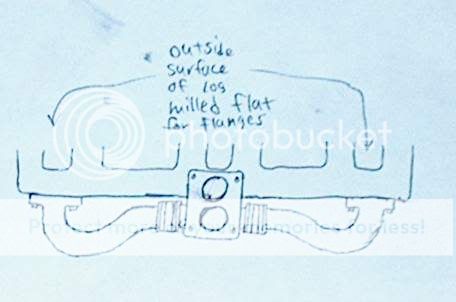

First a few picture from the complete engine.

Want to run the engine outside the car without transmission.

So i take off the transmission in the understanding the flywheel balance wheel(flexplate don't know the correct name)will stay in place, that's correct but a big part of the transmission is still on the main shaft.

Now my plan is to take of the big belthouse from the tranmission and place it back over the big black thing. In this way i can mount the starter also back in place.

but can i run the engine in this way??? do i damage something?

Because the black device is only supported by the main shaft and not in the belt-house any more.

I tough the tooth wheel will stay in place for the starter only, ore must I attach the complete transmission back to the engine again in order to run it.

Hope you can help me.

Thank you.

With kind regards Paul.

I bought a small block with automatic transmission. The same engine i have in my mustang.

Like to bring it back to live, but stumble on a few problems.

First a few picture from the complete engine.

Want to run the engine outside the car without transmission.

So i take off the transmission in the understanding the flywheel balance wheel(flexplate don't know the correct name)will stay in place, that's correct but a big part of the transmission is still on the main shaft.

Now my plan is to take of the big belthouse from the tranmission and place it back over the big black thing. In this way i can mount the starter also back in place.

but can i run the engine in this way??? do i damage something?

Because the black device is only supported by the main shaft and not in the belt-house any more.

I tough the tooth wheel will stay in place for the starter only, ore must I attach the complete transmission back to the engine again in order to run it.

Hope you can help me.

Thank you.

With kind regards Paul.