So what exactly makes a turbo cam a turbo cam? I always subscribed to the Richard Holdener theory that every cam is a turbo cam. Whatever power curve you had before a turbo you’ll have the curve, just more power. It makes sense because all the turbo does is compress the air to be more dense. It still flows the same volume of air as it did before, just denser air.

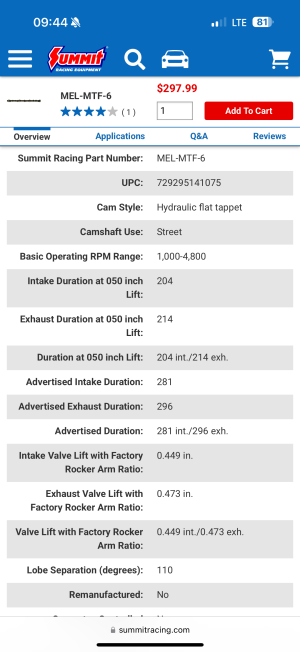

After @pmuller9 chastised me for buying a Melling MTF6 cam I’ve been thinking more about it. He said it’s a bad turbo cam because it has too much exhaust duration. In Richards video he shows multiple dyno graphs to illustrate his point, but on the dyno it’s always wide open throttle. So maybe it doesn’t matter at WOT but under regular cruising it would? Is the difference the spool rate? Cam A will spool the turbo quicker than cam B, and that’s what makes it a better turbo cam?

As always any info is greatly appreciated. The amount of knowledge on this forum is unbelievable and everyone is always so helpful. Any pointers to other resources to learn more would be appreciated! I included the link to the video mentioned in case anyone is interested.

After @pmuller9 chastised me for buying a Melling MTF6 cam I’ve been thinking more about it. He said it’s a bad turbo cam because it has too much exhaust duration. In Richards video he shows multiple dyno graphs to illustrate his point, but on the dyno it’s always wide open throttle. So maybe it doesn’t matter at WOT but under regular cruising it would? Is the difference the spool rate? Cam A will spool the turbo quicker than cam B, and that’s what makes it a better turbo cam?

As always any info is greatly appreciated. The amount of knowledge on this forum is unbelievable and everyone is always so helpful. Any pointers to other resources to learn more would be appreciated! I included the link to the video mentioned in case anyone is interested.