tjnavyblue

Well-known member

Hey folks.

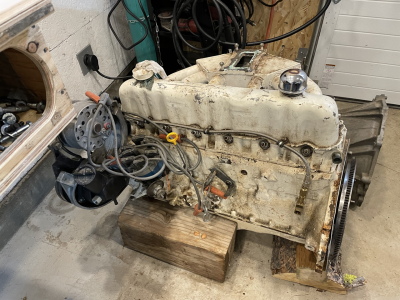

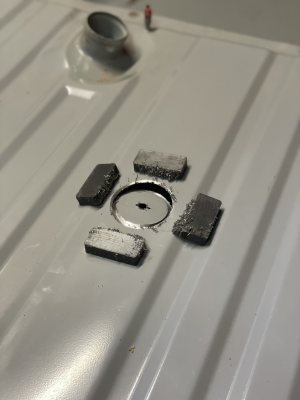

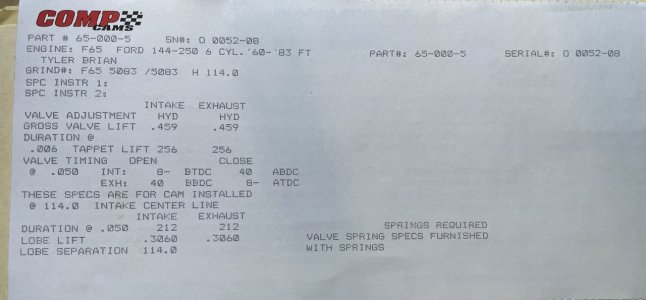

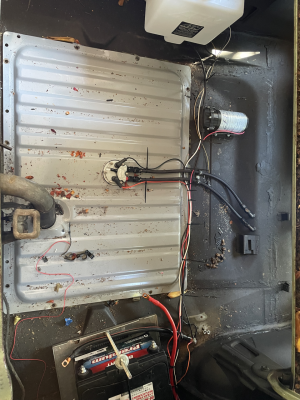

Got a turbo 250 project here. Some of you will recognize this motor. I started building it with Jake Good, JGTurbo, about 20 years ago. It was fired up NA and broke in for about 2000 miles, before I swapped in a V8 to sell the car and stowed this 250 and all the turbo related parts in a barn for over a decade. Here's where it sits as of today:

This project was started when I was younger, poorer, less experienced. Life happens, and necessitated selling the car it was originally in, but I kept the motor.

Fast forward to January 2024 and I'm about to start in on a squarebody Chevy 5.3 LS turbo project. But one night I was down at the barn - and got to looking at the engine over a couple of beers, thinking about how it never really saw it's potential. It just never sat right with me the way it ended.

So - I'm gonna finish it, figure out how much power it makes and give as much info and my own lessons learned as I can back to the community.

So that's the plan. This is not a precious restoration kind of project. I'm just going to document it for the community and for my own sake of just closing the chapter and learning something. Follow if it interests you.

DISCLAIMER:

I just want to say up front here - for any especially younger person that has just bought a 60/70's Ford with an inline 6 and thinks that turbo-ing it is a good or unique idea and thus somehow landed here reading this thread of me doing exactly that: probably just don't do it.

These Ford small sixes are NOT a good performance platform. Just get it running and enjoy it for what it is.

These motors with typical bolt ons - headers, 2V carb, DUI timing - will make about 100 WHP on a good day. Often more like 80 WHP. See Dyno 6A in that link for a realistic sense of what you'll get with a log head motor with cam and all the bolt ons. Which is fine. It is what it is. Leave it alone. Even with the new head and intake and EFI they only make 150whp.

You'll see some folks saying that "a hopped up six can surprise a V8" or some variation on this quote, and I think it's a little misleading. That could have been true until about the early 90's (when Corvettes still made 185hp) but it's just not anymore. I wish someone had given it to me straight when I was a 20 year old kid.

To make power with these motors, you have to use forced induction. Research this. Don't trust anything except dyno sheets or ET/MPH through the traps. Take with many grains of salt speculation on a cars weight or power. It's great to love your car, but that's not math.

To boost one of these is not complicated, but it is expensive and it is delicate in the tune - the chambers are shrouded and prone to detonation and hot spots. They're unforgiving. A single episode of overboost or lean AFRs can destroy an engine in less than a second. And it's a lot of down time with your car - this isn't a weekend or even month long project. Most ford small six turbo projects on this forum start well intentioned but end up years long. Just double check yourself - is that what you're prepared for?

I say all of this because I think one of the worst things that can happen to a young person just getting into cars (Ford inline 6 cars from the 60's can still be bought as runners for sub $5k, so they're attractive to younger/shallower pockets) is making modifications that take the car off the street for long periods of time.

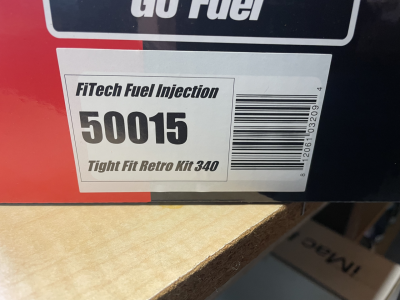

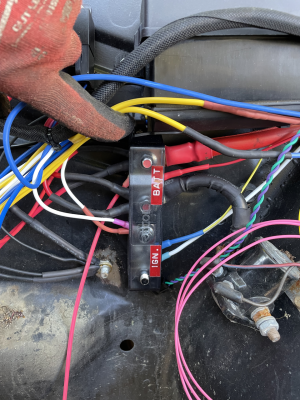

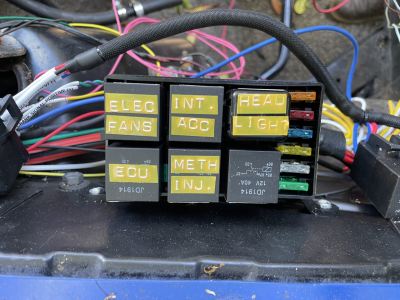

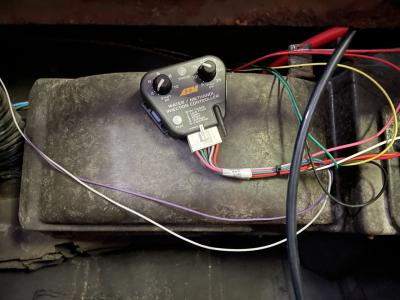

It does not make sense to turbo one of these unless you control your afr's against boost, and timing against boost, and detonation at all times. A Holley Super Sniper complete system is currently the only off the shelf way to do that (with a 2.5 bar MAP), with timing control (dizzy, coil, box) for a little over $2k all in, in May of 2024. Add in a progressive water/meth kit (also kind of a necessity IMHO) for a little more tuning window, and you're at $2500.

So just do the quick math - you don't yet have a car, an engine, a turbo, intercooler or a fuel system and you're already at $2500 just for the EFI, spark and water/meth. Motor with machine work and forged pistons is going to be $4k minimum. Turbo kit - varies a lot. Let's say $1k for turbo and intercooler, wastegate and BOV for cheap Chinese stuff (which I have no problem using). Fuel system - at least $500.

This is already $8k to make 180 to 400 finnicky WHP and take your car off the road for months. And I'm talking about the absolute cheapest side of things. We still haven't talked transmission, rear end, wheels/tires or suspension and brakes. All of which you... need.

Sure, if you've built a bunch of other hot rods, have the pockets, the experience and the context for approaching something like this - that's different. But being informed is really important, especially for young folks with a first old car. I wasn't back then. I am more so now. So I'm going to try to share as much info as I can in this thread. If you're still reading - here we go.

Got a turbo 250 project here. Some of you will recognize this motor. I started building it with Jake Good, JGTurbo, about 20 years ago. It was fired up NA and broke in for about 2000 miles, before I swapped in a V8 to sell the car and stowed this 250 and all the turbo related parts in a barn for over a decade. Here's where it sits as of today:

This project was started when I was younger, poorer, less experienced. Life happens, and necessitated selling the car it was originally in, but I kept the motor.

Fast forward to January 2024 and I'm about to start in on a squarebody Chevy 5.3 LS turbo project. But one night I was down at the barn - and got to looking at the engine over a couple of beers, thinking about how it never really saw it's potential. It just never sat right with me the way it ended.

So - I'm gonna finish it, figure out how much power it makes and give as much info and my own lessons learned as I can back to the community.

So that's the plan. This is not a precious restoration kind of project. I'm just going to document it for the community and for my own sake of just closing the chapter and learning something. Follow if it interests you.

DISCLAIMER:

I just want to say up front here - for any especially younger person that has just bought a 60/70's Ford with an inline 6 and thinks that turbo-ing it is a good or unique idea and thus somehow landed here reading this thread of me doing exactly that: probably just don't do it.

These Ford small sixes are NOT a good performance platform. Just get it running and enjoy it for what it is.

These motors with typical bolt ons - headers, 2V carb, DUI timing - will make about 100 WHP on a good day. Often more like 80 WHP. See Dyno 6A in that link for a realistic sense of what you'll get with a log head motor with cam and all the bolt ons. Which is fine. It is what it is. Leave it alone. Even with the new head and intake and EFI they only make 150whp.

You'll see some folks saying that "a hopped up six can surprise a V8" or some variation on this quote, and I think it's a little misleading. That could have been true until about the early 90's (when Corvettes still made 185hp) but it's just not anymore. I wish someone had given it to me straight when I was a 20 year old kid.

To make power with these motors, you have to use forced induction. Research this. Don't trust anything except dyno sheets or ET/MPH through the traps. Take with many grains of salt speculation on a cars weight or power. It's great to love your car, but that's not math.

To boost one of these is not complicated, but it is expensive and it is delicate in the tune - the chambers are shrouded and prone to detonation and hot spots. They're unforgiving. A single episode of overboost or lean AFRs can destroy an engine in less than a second. And it's a lot of down time with your car - this isn't a weekend or even month long project. Most ford small six turbo projects on this forum start well intentioned but end up years long. Just double check yourself - is that what you're prepared for?

I say all of this because I think one of the worst things that can happen to a young person just getting into cars (Ford inline 6 cars from the 60's can still be bought as runners for sub $5k, so they're attractive to younger/shallower pockets) is making modifications that take the car off the street for long periods of time.

It does not make sense to turbo one of these unless you control your afr's against boost, and timing against boost, and detonation at all times. A Holley Super Sniper complete system is currently the only off the shelf way to do that (with a 2.5 bar MAP), with timing control (dizzy, coil, box) for a little over $2k all in, in May of 2024. Add in a progressive water/meth kit (also kind of a necessity IMHO) for a little more tuning window, and you're at $2500.

So just do the quick math - you don't yet have a car, an engine, a turbo, intercooler or a fuel system and you're already at $2500 just for the EFI, spark and water/meth. Motor with machine work and forged pistons is going to be $4k minimum. Turbo kit - varies a lot. Let's say $1k for turbo and intercooler, wastegate and BOV for cheap Chinese stuff (which I have no problem using). Fuel system - at least $500.

This is already $8k to make 180 to 400 finnicky WHP and take your car off the road for months. And I'm talking about the absolute cheapest side of things. We still haven't talked transmission, rear end, wheels/tires or suspension and brakes. All of which you... need.

Sure, if you've built a bunch of other hot rods, have the pockets, the experience and the context for approaching something like this - that's different. But being informed is really important, especially for young folks with a first old car. I wasn't back then. I am more so now. So I'm going to try to share as much info as I can in this thread. If you're still reading - here we go.

Last edited: