Hello, I was asked to give the particulars of my build so I figured I would start a new post so it is easier to find for anyone doing a search or may be interested in doing this.

First let me say that my intention with this project was to take a page from Linc's 200 project drag car and adapt his idea to my daily driver. I too am very budget conscious and used what I had while spending the necessary money where needed for reliability and always erred on that side of the coin instead of trying for a few extra horsepower. I have not taken the car to the dragstrip and doubt that I will, but I have raced before and would guess by my experience in "seat-of-the-pants-ology" that it is a 14 second car at 5 pounds of boost. I took it up to 15 PSI once and it pulled VERY hard and felt like a 13 second car without a doubt. Nothing to write home about, but keep in mind this car runs 87 octane, starts immediately in 10 below zero weather, commutes 400 miles to work, on a weekly basis, and returns 30+ miles per gallon.

There are many new parts on this project and a ton of used ones as well, but they all work just the same. I will try to summarize what I did and the mods I made but will gladly elaborate for anyone that needs that info. Just ask. 8)

My pile of parts are as follows:

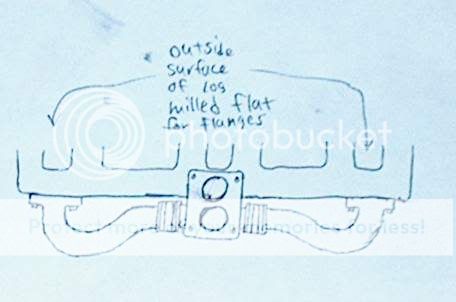

1979 large log 200, all stock with a fresh re-ring and bearings, 260 comp cam, stock short block, no special head work etc. just real bread and butter stuff here. One barrel Holley 1946 carb with a few mods, a boost referenced mechanical pump and a DS2 with timing locked at 28 ish degrees.

I installed the fresh engine in the car last winter along with a T5, it was previously an automatic car. I drove it for a while naturally aspirated and broke it in and I then added the turbocharger on a long weekend as this is my daily driver and it had to get me to work the following Monday.

The turbocharger is a cheap eBay hybrid unit with an internal watsegate, 50 trim wheel, .63 A/R hotside/.50 A/R coldside. It is a 150 dollar turbo brand new all day. I planned to replace it with a better unit at the first sign of trouble but it has been absolutely trouble free so far. I also bought a cheap intercooler and installed it at the same time. Turbo Oil supply and drain lines were stuff I had in the garage from other projects and the intercooler piping was leftover 2.25" exhaust scraps and radiator hose. I made the carb hat out of sheetmetal and more scraps.

The other guys (Linc's200 and Bort62) detailed the actual installation and all that is entailed much better than I ever could so I won't bore you with that stuff, but one thing they were right about is the need for a ton of welding. I bought a used 110 volt wire feed welder and I basically taught myself to weld with it on this project, Its nothing to be afraid of guys, really.

I will update with some more info if I think of it or answer any questions on here or via PM. I will be glad to help anyone where I can.

First let me say that my intention with this project was to take a page from Linc's 200 project drag car and adapt his idea to my daily driver. I too am very budget conscious and used what I had while spending the necessary money where needed for reliability and always erred on that side of the coin instead of trying for a few extra horsepower. I have not taken the car to the dragstrip and doubt that I will, but I have raced before and would guess by my experience in "seat-of-the-pants-ology" that it is a 14 second car at 5 pounds of boost. I took it up to 15 PSI once and it pulled VERY hard and felt like a 13 second car without a doubt. Nothing to write home about, but keep in mind this car runs 87 octane, starts immediately in 10 below zero weather, commutes 400 miles to work, on a weekly basis, and returns 30+ miles per gallon.

There are many new parts on this project and a ton of used ones as well, but they all work just the same. I will try to summarize what I did and the mods I made but will gladly elaborate for anyone that needs that info. Just ask. 8)

My pile of parts are as follows:

1979 large log 200, all stock with a fresh re-ring and bearings, 260 comp cam, stock short block, no special head work etc. just real bread and butter stuff here. One barrel Holley 1946 carb with a few mods, a boost referenced mechanical pump and a DS2 with timing locked at 28 ish degrees.

I installed the fresh engine in the car last winter along with a T5, it was previously an automatic car. I drove it for a while naturally aspirated and broke it in and I then added the turbocharger on a long weekend as this is my daily driver and it had to get me to work the following Monday.

The turbocharger is a cheap eBay hybrid unit with an internal watsegate, 50 trim wheel, .63 A/R hotside/.50 A/R coldside. It is a 150 dollar turbo brand new all day. I planned to replace it with a better unit at the first sign of trouble but it has been absolutely trouble free so far. I also bought a cheap intercooler and installed it at the same time. Turbo Oil supply and drain lines were stuff I had in the garage from other projects and the intercooler piping was leftover 2.25" exhaust scraps and radiator hose. I made the carb hat out of sheetmetal and more scraps.

The other guys (Linc's200 and Bort62) detailed the actual installation and all that is entailed much better than I ever could so I won't bore you with that stuff, but one thing they were right about is the need for a ton of welding. I bought a used 110 volt wire feed welder and I basically taught myself to weld with it on this project, Its nothing to be afraid of guys, really.

I will update with some more info if I think of it or answer any questions on here or via PM. I will be glad to help anyone where I can.

Just need a turbo that makes more than your system loses :rolflmao:

Just need a turbo that makes more than your system loses :rolflmao: