Double Flair 3/16 “ Break Lines

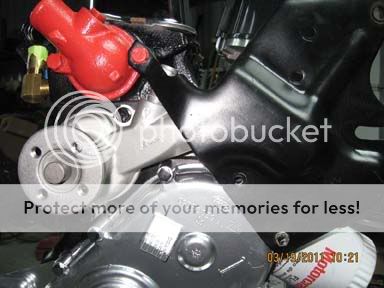

CobraSix gave me the idea to change my single cylinder master cylinder to a dual cylinder. Thank ya CobraSix.

I took pix of the change over but I cant find where I put them.

But CobraSix has a good review

HERE

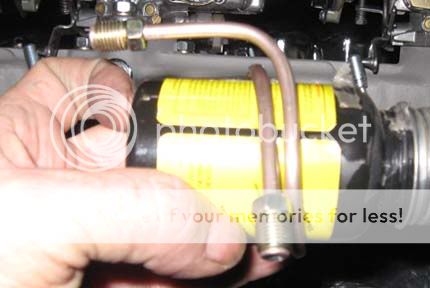

I used 3/16 “ CNF-3B Cunifer Alloy Brake Line from

FEDHILL

The use of FEDHILL idea came from jdn21758. Thank you jdn21758 it works great…

I had the good fortune of growing up wid a twin brother. I could never tape and float an inside corner. I could never get a good double flair using the tube cutter.

My brother could tape and float an inside corner fast, sharp as a tack and smooth as silk. He could also make a double flair using the normal tube cutter with one eye closed, the other eye staring at me and laughing his (buttock) off.. at me.. :mrgreen:

Any way this is how I dun did it and I don’t see any leaks..

I started here.. Thank you CobraSix..

As you can see my tube cut sucked big time. So I fell back on my trusty ban saw. Good straight cut.

1: File burs off and straight.

2: File a good chamfer

3 & 4: I Used 500 grit and repeated 1 & 2:

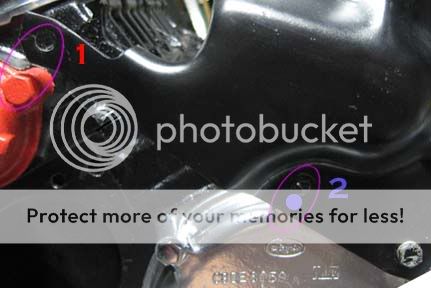

The left image is flushed to top of fitting or miss slightly on the low side.

Right side with fitting in place and a drop of oil.

1: With fitting centered ready to shape this guy.

2: Compressed until fitting is flush with holding tool.

1: I removed the 1 st flair tool then applied oil to the head and compressed until I ran out of strength.

2: What I ended up wid..

Another look at the results. On the right side you can see the only mark the tool left. Not bad at all for me any way..

My Prototype. Man I like high-plooten words… Worked great.

A plastic bottle of liquid tape and I had a perfect form.

Finished and in place. Don’t look half bad..