goldfinger1957

Well-known member

Ok, it's been a while but this is what's been done.

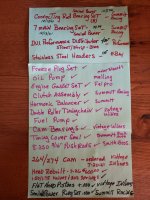

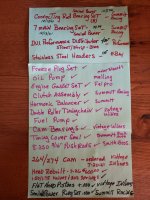

Pulled the 200 and rebuilt the head. Nothing fancy but put 1.50 & 1.75 intake and exhaust valves along with 302 springs and viton seals. Also took .090 off of head. ( small log head )

Bottom end. New silverlite flat top pistons and moly ring set. (+.030 over) New 264/274 cam, bearings ect. ect....

Oil pump, fuel pump, ARP fasteners, water pump, new harmonic balancer, double roller timing chain, push rods, stainless steel headers and DUI distributor ( street/strip)...along with new clutch assembly for the " on a tree "...No A/C and no Power steering. Waiting on the Weber 32/36 conversion carburetor with manual choke.

All that said I've got 3 qurstions:

1. Without a Dyno, any guesses as to the available horse power or am I still looking at 120 hp after all this ?

2. Given i ordered the DUI without all the additional information provided will this need to be "revurved" and is it really necessary?

3. Short of a blower, nitrous or a turbo charger is their anything I'm missing to get the most power I can out of this assembly ? ( roller rockers were pricey)...

Not sure what else I could do, besides the 250 cylinder head swap which I'm not doing. And wondering if I should just spend a little more money and buy the EFI rather than the Weber 32/36.

I've pretty much fillowed the Ford Six Performance handbook .

Looking forward to your input. Go ahead..I can take it...lol

Pulled the 200 and rebuilt the head. Nothing fancy but put 1.50 & 1.75 intake and exhaust valves along with 302 springs and viton seals. Also took .090 off of head. ( small log head )

Bottom end. New silverlite flat top pistons and moly ring set. (+.030 over) New 264/274 cam, bearings ect. ect....

Oil pump, fuel pump, ARP fasteners, water pump, new harmonic balancer, double roller timing chain, push rods, stainless steel headers and DUI distributor ( street/strip)...along with new clutch assembly for the " on a tree "...No A/C and no Power steering. Waiting on the Weber 32/36 conversion carburetor with manual choke.

All that said I've got 3 qurstions:

1. Without a Dyno, any guesses as to the available horse power or am I still looking at 120 hp after all this ?

2. Given i ordered the DUI without all the additional information provided will this need to be "revurved" and is it really necessary?

3. Short of a blower, nitrous or a turbo charger is their anything I'm missing to get the most power I can out of this assembly ? ( roller rockers were pricey)...

Not sure what else I could do, besides the 250 cylinder head swap which I'm not doing. And wondering if I should just spend a little more money and buy the EFI rather than the Weber 32/36.

I've pretty much fillowed the Ford Six Performance handbook .

Looking forward to your input. Go ahead..I can take it...lol