You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This will be fun

- Thread starter Ikosix

- Start date

You would do the work around the valve guide in the bowl before the head goes into the shop.

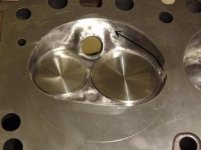

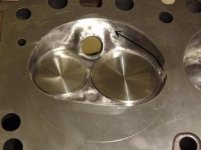

This is the intake.

The exhaust bowl guide is just cut straight across.

You also have the option of working on the combustion chamber.

Are you good with a die grinder?

I prefer ordering from Summit whenever possible.

This is the intake.

The exhaust bowl guide is just cut straight across.

You also have the option of working on the combustion chamber.

Are you good with a die grinder?

I prefer ordering from Summit whenever possible.

Last edited:

Yes. I just bough a couple new burrs. I’ll give it a shot. I’ve read some of your advice to others on the topic. It looks like fun. Thanks! I just ordered the springs and retainers. I can’t seem to find a 1.625” installed height rocker stud. I’m sure I just need to look harder. I’m not opposed to buying new rocker if you think it’d be a better setup

You can use the ARP SBC 1.75" 3/8 stud and take .100" off the stud towers.

You will have to use the ARP locks also.

I like the Harland Sharp roller rockers. I was just trying to keep the budget low.

If you go that direction you might think about using the 1.75 ratio rocker arm which would add more valve lift.

You will have to use the ARP locks also.

I like the Harland Sharp roller rockers. I was just trying to keep the budget low.

If you go that direction you might think about using the 1.75 ratio rocker arm which would add more valve lift.

Last edited:

You can do most of the work in the bowl and combustion chamber with large and small cone/radius-end burrs.

The port walls coming to the bowl from the manifolds only need to be cleaned up without much material removed.

That can be done with a cylindrical/radius-end burr.

This is my preference but you may prefer some other variation of burrs.

If you are going to use a HS roller rocker, hold off on deciding which ratio until you actually have the cam.

The port walls coming to the bowl from the manifolds only need to be cleaned up without much material removed.

That can be done with a cylindrical/radius-end burr.

This is my preference but you may prefer some other variation of burrs.

If you are going to use a HS roller rocker, hold off on deciding which ratio until you actually have the cam.

Last edited:

It is a custom cam so you will need to order directly from Crower.

If you know for sure that you want to use the HS roller rocker arms you could use the larger 7/16" stud which will have less flex but that means there's no going back to stock stamped rockers.

If you use the roller rockers the stud towers may not need to be shortened.

The roller rockers may need the extra stud height.

If you know for sure that you want to use the HS roller rocker arms you could use the larger 7/16" stud which will have less flex but that means there's no going back to stock stamped rockers.

If you use the roller rockers the stud towers may not need to be shortened.

The roller rockers may need the extra stud height.

Last edited:

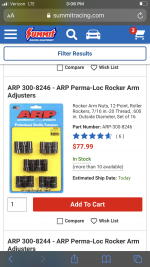

That’s what I was thinking thanks. So I ordered the cam and lifters they will take a month to get here. I have the studs in he cart at Summit. I wasn’t sure which locks to order with them. These are the style but there’s a couple choices in the 7/16x20. I thought it might depend on the rockers which brings me to my next question. Should I wait to order them still?

Attachments

Those are the correct locks. The HS rockers for the 7/16" stud use a .600" body diameter lock.

The HS roller rockers come with locks. I know ARP says to use their Perma-Locs but no one using the HS locks have reported a problem when used with a hydraulic lifter.

I mentioned using a HS 1.75 ratio rocker to pick up some extra torque but that also puts extra stress on the lifters and pushrods.

Extra torque can always be added by running more boost.

So I'm going to recommend staying with the 1.6 ratio 7/16" HS roller rocker PN S4002-7

The HS roller rockers come with locks. I know ARP says to use their Perma-Locs but no one using the HS locks have reported a problem when used with a hydraulic lifter.

I mentioned using a HS 1.75 ratio rocker to pick up some extra torque but that also puts extra stress on the lifters and pushrods.

Extra torque can always be added by running more boost.

So I'm going to recommend staying with the 1.6 ratio 7/16" HS roller rocker PN S4002-7

benchracer

Well-known member

which yr. head is pictured?

The top picture of just the intake port is an aftermarket Engine Quest head.which yr. head is pictured?

The bottom two pictures of the exhaust port and the combustion chamber is an 1985 300 head with Chevy 2.02" intake and 1.60" exhaust valves.

Nice find!

The stock wastegate canister is set for very high boost.

I don't know if the spring in the canister can be changed.

Also regulating at a lower boost requires a larger wastegate port since you have to dump more exhaust.

You can slowly apply air pressure with a regulator to see when the wastegate begins to open.

If you go to an external wastegate you can set it for low boost and be be able to increase the boost by using a simple pressure regulator.

The stock wastegate canister is set for very high boost.

I don't know if the spring in the canister can be changed.

Also regulating at a lower boost requires a larger wastegate port since you have to dump more exhaust.

You can slowly apply air pressure with a regulator to see when the wastegate begins to open.

If you go to an external wastegate you can set it for low boost and be be able to increase the boost by using a simple pressure regulator.