You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

This will be fun

- Thread starter Ikosix

- Start date

(removed)

Can't count the times I've done that

Can't count the times I've done that

Last edited:

You can also go back and edit too.

Just some thoughts on using the integral waste gate. As pmuller says, check the pressure required to crack and to fully open the gate valve. And there may be some flexibility there depending on push-rod adjustment that determines the amount of spring pre-load. I doubt you can change the spring without cutting the can apart but you may be able to find an alternative actuator from another application that will be more in line with what you want.Nice find!

The stock wastegate canister is set for very high boost.

I don't know if the spring in the canister can be changed.

Also regulating at a lower boost requires a larger wastegate port since you have to dump more exhaust.

You can slowly apply air pressure with a regulator to see when the wastegate begins to open.

If you go to an external wastegate you can set it for low boost and be be able to increase the boost by using a simple pressure regulator.

Regarding improving waste gate flow, would it be possible to open up the valve seat and use a larger valve head? Something to look into.

I intend to use the internal waste gates on my project as it simplifies the down-pipe plumbing and saves the cost of, in my case, two waste gates.

Thank you for this. I’ve already ordered the non wastegate housing. I’m wondering would the top of the HD manifold work for wastegate. I could probably build a custom piece for this. I’m assuming usually it’s just blocked off with a plate. Maybe there’s not room between the intake and exhaust manifolds. Just a thought.

Firepower354

Famous Member

Thank you for this. I’ve already ordered the non wastegate housing. I’m wondering would the top of the HD manifold work for wastegate. I could probably build a custom piece for this. I’m assuming usually it’s just blocked off with a plate. Maybe there’s not room between the intake and exhaust manifolds. Just a thought.

With the 1v, the smaller opening is direct to intake, so an EFI will require a blockoff anyway. Mine's welded shut. You'd have to cut some of the bracing between the center runners, But it seems like a 2x1 section of tube could extend out, and mount the wastegate to the bottom of it.

Obv not an EFI but shows the space.

I removed it from the thread because I figured you would post it when you were ready.Pmuller I got the housing off. It fought till the end but I won. I saw that you asked on my email alerts but didn’t see in the thread.

No need to have extra post in your thread like this one. LOL

All you need to complete the parts collection picture is a Christmas tree.

So Matt at VI just let me know he can’t get the larger valve set from SI. He said SI will only ship them on a bulk order. I guess they aren’t a stock item. Do you think I should order the SBC valves? If so are they going to be compatible with the HS rockers and valve springs and push rods?

Thanks

Thanks

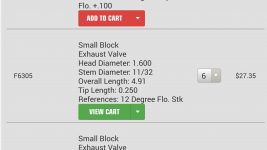

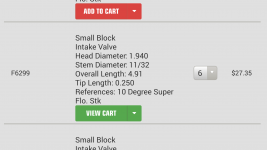

I’ve almost got the bowl work done on the head then it’s going to the shop. I’m having a hard time getting valves from SI. They don’t have any SBC valves for a few weeks. He recommended calling Ferrea. I found these on their site.

Whadaya think?

Whadaya think?

Attachments

Here’s an update on progress thus far. I got the head back from the machine shop Friday. It looks nice. I guess the next step is to cc the chambers. I need to get a head gasket ordered or at least figure out what I’m gonna use. Any preference?

Also what are y’all usin for a valve cover that fits over these rollers?

Thanks!

Also what are y’all usin for a valve cover that fits over these rollers?

Thanks!