I will participate on this thread's train of dots, and do my part to help connect them while I wait for Admin solutions to posting issues.

Multiple points to consider here from the rich side. First, the purpose of "rich" and what it does, then the use of "rich" for certain applications. Power applications use optimal max-torque fueling for optimal power; not too rich and not too lean for peak torque. Just right. Note the reference to "rich" is relative to best power AFRs, not stoichiometric as referenced in the first post to emissions.

When you say "it's running a bit rich", you are referring to rich of your best tuning, not rich of stoich, right? So, "rich" is relative to peak power in this discussion.

Peak power Lambdas/AFRs are certainly 'hot' from the standpoint that the engine is doing maximum work and

total heat production is high, so your cooling system better be good so it doesn't over-heat; but the combustion is not relatively hot, and is burning at the optimal AFR to convert fuel to energy. Important relationships and terms. All good.

Power does not melt parts at optimal fueling and timing, as temperatures are right where they should be, NA or power-adder. We can see evidence of this on our spark plugs. We are assuming at this point the fuel octane is sufficient and ignition timing correct, so they are not factors involved in AFRs at this point. There is no reason to run rich of optimal power AFRs if all is good. End of story.

Ah, but octane and timing do come into play, especially if insufficient or incorrect. Here is where AFR manipulation comes into play, often incorrectly.

Detonation is caused by heat. Period. Many sources of cumulative heat, from compression heat to intake heat, coolant heat, spark plug and exhaust valve heat, and so on. Some confusion results from comments to always run rich or timing retarded in order to delay combustion and resulting peak cylinder pressure point (crank angle), typically to avoid detonation. Delayed PCP means late burn = lower pressure = reduced tendency to det on low octane.

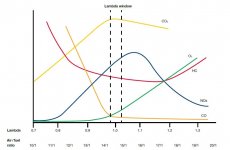

Again, correct PCP is required for max efficiency, which translates to power, or economy, emissions, etc - in this case power. If timing is correct, and fuel is correct, but octane is low and detonation is detected, one option is to slow the burn by adding more fuel. Peak-torque fueling is fastest burn, while richer or leaner are slower. Delaying PCP adds late-heat, but is somewhat offset by added excess over-rich cooling fuel. A band aid and inefficient de-tune, and it works sometimes in a pinch when you can't get better fuel - but there are downsides.

Conversely, with low octane and potential for detonation; we could delay the burn by retarding timing, to again delay and lower PCP for a similar de-tuning effect. What is not good is adding these delays if you don't need them, as you just reduce power and add late-heat, and the problem returns with a vengeance on long pulls as that added late-heat accumulates. Unfortunately, juggling fuel and timing to get past issues tends to result in chasing one's tail, more retard needs more fuel, but eventually needs more retard... vicious cycle. Of course, we could also de-tune by reducing throttle for the same effect, but it's against our nature to do that.

Note in all these cases the burn rate will change with AFR, a little or a lot, which means ignition timing that

was correct is now not correct. Richer or retarded is often claimed to be "safe". It is not. Correct, where the engine is happiest, is safest. Especially timing, retarded means lower efficiency, reduced power or economy, and added heat. Fuel and spark are a team, so when you change fueling, you change timing.

Yes, rich from best power. It reduces performance as a de-tune, but helps the immediate issue of detonation, which

does melt parts. Literally. As it heats and melts stuff by blasting-off the boundary layer of insulating air clinging to the parts, the accumulated heat can also ignite the incoming fuel before the spark occurs, called pre-ignition. Even more destructive than detonation, and can destroy the engine in one stroke. As a diagnostic in engine failure analysis, a "holed" piston is one softened by detonation, but then blown-through by the extreme pressure of pre-ignition on the up-stroke. Bent rods and lifted heads are yet other signs of pre-ig. While all of these comments are related to rich and lean, they are focused on the why's of rich, but also how they are different than lean.

Knowing all that, what about "lean"? How about adding timing to stop detonation?

Yes, following the above principles, I have had that situation, and it highlights using the correct timing found by tuning, not advanced or retarded by suggestion or guessing. In this case, I was diagnosing an engine that would cruise fine, but then began to creep into detonation after a bit. The short story is that vacuum advance was not sufficient at lean cruise, the late-heat of the effective retard heated the spark plug and exhaust valve, and it accumulated enough heat to initiate detonation increasing with time. Solution? Add timing to

correct timing, increasing efficiency and economy, reducing late-heat, and solving the detonation issue completely.

Moral of the story is to build the engine to use the chosen fuel, or use fuel with sufficient octane for the engine build. Else, there are workarounds, but never as-effective or reliable as using the right stuff, tuned for best values. How best fueling and best timing are found in tuning might be a good next-step. Hope that helps.