Heyo! Recently picked up a 200 from someone locally that was doing a V8 swap on their mustang. When I came to view it before purchasing, I saw it fire up cold, ran well, didn't have really any issues to speak of. I thought I was going to be on easy street, and got it for a reasonable deal.

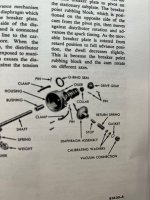

Before installing in the van, I did a small tune up job - fresh gaskets all over, new plugs and wires, HEI Distributor, and a sweet enamel rattle can job. I spent a couple of months working on it in a stand, a few hours a week, and thought I had done something that I'd really be proud of. It looked great and installed fairly easily.

After getting everything hooked up, the first crank was met with a large smoke cloud and pretty substantial puddle of coolant. The one thing I had not given attention to was the head gasket, due to the fact that I saw the engine run without any similar type of issue. So I removed the head to inspect and couldn't see anything obvious, but replaced the head gasket, and tried again - came up with the same issue. I took the head in for machining and found it needed a bit of planing. This did the trick, and after getting everything assembled with new head bolts and a fresh gasket, she fired up without the water in the cylinders.

But she wouldn't idle. She will rev, but will die instead of resting at an idle. I had another Autolite 1100 carb so I did a swap and found the issue was persistent. I drained the gas from the tank and added some fresh 91, still no idle. I replaced the metal vacuum line with a fresh rubber hose, still no idle. I disassembled the carb, blew it all out with carb cleaner, sealed it back up, and got a hint of idle, but nothing of substance. After a few cranks while fiddling with the distributor position and idle screw, the battery seems to have taken a crap, and she wasn't even firing up.

Have I gone overboard? Or is there something small that I am overlooking? I know that a fresh battery wouldn't hurt, it's damn near 4 years old, but could that really be the solution to my mounting woes?

Thanks for any input/advice/help/support you might have to offer, I am running on fumes (emotionally).

Before installing in the van, I did a small tune up job - fresh gaskets all over, new plugs and wires, HEI Distributor, and a sweet enamel rattle can job. I spent a couple of months working on it in a stand, a few hours a week, and thought I had done something that I'd really be proud of. It looked great and installed fairly easily.

After getting everything hooked up, the first crank was met with a large smoke cloud and pretty substantial puddle of coolant. The one thing I had not given attention to was the head gasket, due to the fact that I saw the engine run without any similar type of issue. So I removed the head to inspect and couldn't see anything obvious, but replaced the head gasket, and tried again - came up with the same issue. I took the head in for machining and found it needed a bit of planing. This did the trick, and after getting everything assembled with new head bolts and a fresh gasket, she fired up without the water in the cylinders.

But she wouldn't idle. She will rev, but will die instead of resting at an idle. I had another Autolite 1100 carb so I did a swap and found the issue was persistent. I drained the gas from the tank and added some fresh 91, still no idle. I replaced the metal vacuum line with a fresh rubber hose, still no idle. I disassembled the carb, blew it all out with carb cleaner, sealed it back up, and got a hint of idle, but nothing of substance. After a few cranks while fiddling with the distributor position and idle screw, the battery seems to have taken a crap, and she wasn't even firing up.

Have I gone overboard? Or is there something small that I am overlooking? I know that a fresh battery wouldn't hurt, it's damn near 4 years old, but could that really be the solution to my mounting woes?

Thanks for any input/advice/help/support you might have to offer, I am running on fumes (emotionally).