mad_science

Well-known member

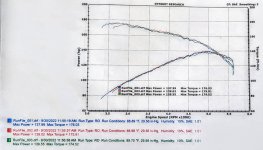

Just ran my 250-powered Ranchero in Lemons, but on Friday we had time to get it dyno-ed.

Figured it could be a useful benchmark for what you get from a build.

The specs:

Results, at the wheels:

140hp @ 5000

175lbft @ 2600-2700

(see attached)

At 10% drivetrain loss, that's 156 crank

15% --> 164 crank

20% --> 175 crank

It makes sense in a way because the Sniper is rated to support 300-350hp and at max RPM we were running the injectors at about 50% duty cycle.

Honestly it's more than I thought we'd get but also basically on par with a mediocre V8.

Figured it could be a useful benchmark for what you get from a build.

The specs:

- 250 D5DE block, standard bore

- 255 V8 pistons

- D3 Head opened up for 2V conversion, decked level but not milled down. Combustion chambers measure 62cc.

- Clay smith 274/274 108 LSA cam

- ^^^Based on my calculations this gives a static CR of 9.58:1 and a dynamic CR of 8.47:1

- Holley Sniper 2300 TBI EFI system kinda sorta tuned, but far from completely dialed in

- eBay HEI distributor, plugs gapped like 35-40thou

- Long tube headers running through dual 2.5" exhausts + glass packs

- Toploader 4 speed, 3.55:1 8" diff

- 205-50-R15 Falken Azenis tires on aluminum wheels

Results, at the wheels:

140hp @ 5000

175lbft @ 2600-2700

(see attached)

At 10% drivetrain loss, that's 156 crank

15% --> 164 crank

20% --> 175 crank

It makes sense in a way because the Sniper is rated to support 300-350hp and at max RPM we were running the injectors at about 50% duty cycle.

Honestly it's more than I thought we'd get but also basically on par with a mediocre V8.