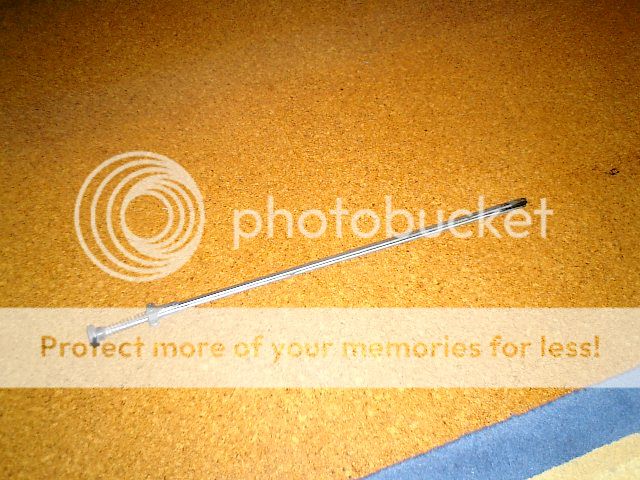

Anybody like to share there tips on changing lifters with the head still on the engine .Ive just done the change but didnt have a lifter tool .All i had was a magnetic extension tool .Most were easy to do but the very front and rear were a real challenge .Whats the secret to changing these two lifters?

If i had to do it again and the engine was older i would certainly take the head off .I assembled my engine with the lifters from my first cam that had only done 100ks ,but thought i better put a new set in with the new crow unit.The engine hasnt been started yet so the cams still new .Checking the lash was easy enough with the book stating between 2.5--5.00mm .What would be the best lash just on 2.5mm or just before 5.0mm ? Mine are measuring 4.5mm totally colapsed.

Dave

If i had to do it again and the engine was older i would certainly take the head off .I assembled my engine with the lifters from my first cam that had only done 100ks ,but thought i better put a new set in with the new crow unit.The engine hasnt been started yet so the cams still new .Checking the lash was easy enough with the book stating between 2.5--5.00mm .What would be the best lash just on 2.5mm or just before 5.0mm ? Mine are measuring 4.5mm totally colapsed.

Dave