You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six Cylinder walls question

- Thread starter goldfinger1957

- Start date

-

- Tags

- 200 inline 6

This relates to all small sixes

The cylinder ridge / lip is left or formed by the top ring's travel of each of the Pistons in the blocks cylinder bores. The answer to your question is going to depend on if you are planing on removing the Pistons and installing a new set of rings into your short block? If your not going to take the Pistons out then it won't mater and you can leave it as is since the old rings are already worn into and all ready match the shape of those ridge lips. Good luck

"yes". A few 10ths of a thousandth is not much. The ol adage is if the finger nail snags good it's time to think abt a hand reamer (its a triangular file, sharp point, bulky diameter) also named scraper to run over the surface. Bigger? to the machine shop. I'd say U have neither here...

Y is the head off?

Y is the head off?

goldfinger1957

Well-known member

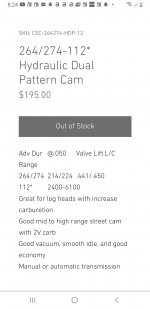

Hey Chad. The engine ran like crap. No power. So I took the head to my machinist to rebuild the 200 head. 1.75 & 1.50 intake/exhaust. Installing new valves with 302 springs. New lifters, New pushrods, fuel pump, water pump, oil pump and DUI distributor along with new double roller timing chain. Once the head is ready I'll give him the bottom end to clean. Check the crank and replace the cam bearings. Im still having trouble finding a 264/274 112° cam for this as no one has blanks right now. Machinist will check pistons and replace rings and check piston bores. I do have a new set of headers to go on when ready to put back into the car."yes". A few 10ths of a thousandth is not much. The ol adage is if the finger nail snags good it's time to think abt a hand reamer (its a triangular file, sharp point, bulky diameter) also named scraper to run over the surface. Bigger? to the machine shop. I'd say U have neither here...

Y is the head off?

goldfinger1957

Well-known member

I'll take a new look and post better picks.Could just be the picture, but I’m a little concerned with cylinder #3. Looks like something got loose in there at one time and nicked the piston top up, and there are some dark vertical areas in the cylinder walls. Check that one out very closely for cracks.

sounds like "a full re-do". No need for immediate back to the rd. Some of us avoid the DUI. Others use the DSII system. U may have "the Handbook" (I C the "use 302 springs") many of us like. The tech archive is above as well:

last, Schnider custom grinds for same price as others do a stock (or is this where the correct blank is missing)?

last, Schnider custom grinds for same price as others do a stock (or is this where the correct blank is missing)?

The Clay Smith 264/274 cam is very close to the same as the Schneider 270-280H cam.

Either of those cams are fairly big for a 200 six if you are looking for a smooth idle and low rpm performance.

What rpm range do you want for a power band?

Either of those cams are fairly big for a 200 six if you are looking for a smooth idle and low rpm performance.

What rpm range do you want for a power band?

goldfinger1957

Well-known member

Vintage Inlines has the exact cam i want for my build but they're out of stock. I've contacted schneider but they're out too and said call back in a couple of weeks. Its the only thing holding me back from starting the bottom end. Even with all the new internal parts and DUI distributor along with the headers and the larger intake /exhaust valves....I'm not sure my horsepower will be that significant. It's really hard to just see what I have and put a number to the horsepower I will achieve but I welcome ALL guesses. I initially was hoping to get 200 HP out of the 200ci straight six. Last item will be the Weber 32/36 carb kit with the straight bolt on feature. If I can squeeze even 150 horsepower I'd be happy considering the parts I have weren't really that expensive, minus the DUI of course...I don't think I'll be running it over 5k rpms that often but I would like to keep up with highway traffic.The Clay Smith 264/274 cam is very close to the same as the Schneider 270-280H cam.

Either of those cams are fairly big for a 200 six if you are looking for a smooth idle and low rpm performance.

What rpm range do you want for a power band?

Attachments

goldfinger1957

Well-known member

Piston walls look good to me. No gouges or scoring. But what's with the grooves on the crank journal caps ?? Is that how they balance the crank ?? Always wondered about that...Could just be the picture, but I’m a little concerned with cylinder #3. Looks like something got loose in there at one time and nicked the piston top up, and there are some dark vertical areas in the cylinder walls. Check that one out very closely for cracks.

Attachments

The grooves are where material has been removed to balance the big end of the rods, so they all weigh the same, the small end is done the same..

Last edited:

goldfinger1957

Well-known member

I wasn't sure but I'm glad you were. I kinda thought so. I'm certain the botton end is all original . If the piston walls are acceptable ill just have the rings replaced along with new crank bearings. Is there anything else I should be doing down there besides new freeze plugs and seals ?The grooves are where material has been removed to balance the big end of the rods, so they all weigh the same, the small end is done the same..

Attachments

If you can catch your fingernail on the ring wear ridge at the top of the cylinder there is risk of your new rings coming into contact with it when running; damaging the top ring

goldfinger1957

Well-known member

That is true and I do have minor wear up top. I was going to purchase a set of moly rings from Summit but I thought I'd hold off until my machinist evaluated the piston bore to see if it needed polishing or possibly go .010 over to get them cleaned up. Would .010 over mean replacing the pistons at that point or would the rings compensate for this ??If you can catch your fingernail on the ring wear ridge at the top of the cylinder there is risk of your new rings coming into contact with it when running; damaging the

Attachments

At this point were just making speculative conversation. Let's see what your machinist says the dimensions your cylinders mic out at. Unless you have access to a bore gage and micrometer.

goldfinger1957

Well-known member

AbsolutelyWith either of those cams you need flat top pistons to get the compression over 10-1.

Your DUI also needs to be recurved for top performance.

I think I should get close to 10:1 by taking the head down .090 which I'm having my machinist do plus the deck will come down at least .005 just to clean it up and make sure its flat. I know I can get flat top pistons from another year/make & model...the name escapes me, but not sure I really need to go that route...

goldfinger1957

Well-known member

I don't have access to them anymore, but I know how to use them. Sometimes you just leave it up to the professionals that have the knowledge and equipment to make it the best it can be. I really want this to perform well without being so radical I spend more time under the hood than behind the wheel. It can't be that difficult to get 150-200 horses out of these inline sixes. Everything will be brand new except for the crank. Not sure what else to purchase, since I've got just about everything covered.At this point were just making speculative conversation. Let's see what your machinist says the dimensions your cylinders mic out at. Unless you have access to a bore gage and micrometer.

Attachments

philford

Famous Member

if you leave the rings im place leave it be. If you change the rings there is a tool called a ridge reamer so the new top compression ring wont get damaged. If you see damage that looks like a piece of a piston ring broke off and got on top of the piston then it may rattle up and down in there and make marks. look around te circumference of that piston if you see any holes there near the edge above the top ring then I'd call the pistons done. you could see vertical scratches from where rings broke and scored the bore.

I think with the extent you are going , fitting oversized pistons and doing a rebore might be best beacuse it's dissapointing to spend money and see it burn oil.

I think you should talk to the mechanic. he may advise better on how far you can let thtings go . consider the cost of new oistons and the block removal and boring. but it's ultimately your decision how much to spend.

the cylinders dont wear evenly because of piston slap etc so you'll probably have more ridge where the wear is higher.

then you can choose to polish the crnk and put in new shells or to turn the crank and you can go on to replacing rod end bearings and such but that might not be necessary. if you still want ot spend more you can get the crank, pistons con rods and flywheel balanced and that will make it smoother especially if you are going to do performance mods.

my gut reaction is do it right and then youll be happy but its easy to just say go spend more money. I like the car it looks nice. you have to decide if you want this to be a "farmer rebuild" or basically a new engine and both make sense under certain conditions.

if you have the option to rebore then you may decide to jsut go the next size up or to go with larger pistons. some blocks have more meat. I increased the size of my volvo from 1800 to 2 liters by using larger pistons. others will know how big you can go with that ford without risking going intot he waterjacket. one school of though tis it probably made it this far and if you do rebuild it it may be good for the life of the car. If you wanted to keep the matching numbers and its somethign really special then you could opt to not remove more but it isnt; much more expensive to punch it out. if you can do that. It might be cheaper than other performance mods. that thing must have pretty good power with that engine. with my old volvo I wanted to end up with a bit more power to keep up in modern day traffic.. I did one wharre I just went from stock to the maximum stock oversize of .o30 and it did make a difference.

I guess if you were serious then you can have the block checked for cracks and things too. you might punch it out and find you want a different block ..

my choice would be to opt for the maximum oversize and then check the crank. If it's not bad I'd polish the crank myself and install new shells if it's bad then regrind the crank. I doubt youll blow up the bottom end but I thik chances are high that if you just do the top end it'll have more compression and burn oil because of the old rings and wear. you could ask the mechanic about the costs of balancing and his opinion. I feel that balancing is nice even if you aren't rodding it.. itll just run smoother at higher revs.

I had new bushings pressed intpo my rods and reamed them that's probably not necessary. when they did that they put the rods in a furnace to expand them before pressing in the new bushings. If you do want ot keep on doing performance mods than there is something to making the block really sound. If you just want it to drive and work than you dont need to go too crazy. It often becomes a personal challenge to do the best you can but then the cost can go up. my brother kept doing the top end on engines and it always seemed to work out a bit disappointing because then it would work a while then burn oil and he would loose interest in the vehicle and not want to open it all back up a second time.

I think with the extent you are going , fitting oversized pistons and doing a rebore might be best beacuse it's dissapointing to spend money and see it burn oil.

I think you should talk to the mechanic. he may advise better on how far you can let thtings go . consider the cost of new oistons and the block removal and boring. but it's ultimately your decision how much to spend.

the cylinders dont wear evenly because of piston slap etc so you'll probably have more ridge where the wear is higher.

then you can choose to polish the crnk and put in new shells or to turn the crank and you can go on to replacing rod end bearings and such but that might not be necessary. if you still want ot spend more you can get the crank, pistons con rods and flywheel balanced and that will make it smoother especially if you are going to do performance mods.

my gut reaction is do it right and then youll be happy but its easy to just say go spend more money. I like the car it looks nice. you have to decide if you want this to be a "farmer rebuild" or basically a new engine and both make sense under certain conditions.

if you have the option to rebore then you may decide to jsut go the next size up or to go with larger pistons. some blocks have more meat. I increased the size of my volvo from 1800 to 2 liters by using larger pistons. others will know how big you can go with that ford without risking going intot he waterjacket. one school of though tis it probably made it this far and if you do rebuild it it may be good for the life of the car. If you wanted to keep the matching numbers and its somethign really special then you could opt to not remove more but it isnt; much more expensive to punch it out. if you can do that. It might be cheaper than other performance mods. that thing must have pretty good power with that engine. with my old volvo I wanted to end up with a bit more power to keep up in modern day traffic.. I did one wharre I just went from stock to the maximum stock oversize of .o30 and it did make a difference.

I guess if you were serious then you can have the block checked for cracks and things too. you might punch it out and find you want a different block ..

my choice would be to opt for the maximum oversize and then check the crank. If it's not bad I'd polish the crank myself and install new shells if it's bad then regrind the crank. I doubt youll blow up the bottom end but I thik chances are high that if you just do the top end it'll have more compression and burn oil because of the old rings and wear. you could ask the mechanic about the costs of balancing and his opinion. I feel that balancing is nice even if you aren't rodding it.. itll just run smoother at higher revs.

I had new bushings pressed intpo my rods and reamed them that's probably not necessary. when they did that they put the rods in a furnace to expand them before pressing in the new bushings. If you do want ot keep on doing performance mods than there is something to making the block really sound. If you just want it to drive and work than you dont need to go too crazy. It often becomes a personal challenge to do the best you can but then the cost can go up. my brother kept doing the top end on engines and it always seemed to work out a bit disappointing because then it would work a while then burn oil and he would loose interest in the vehicle and not want to open it all back up a second time.

Last edited:

goldfinger1957

Well-known member

I kind of a "One & Done" kinda guy and if it needs to be bored .020 or .030 over thats fine. I just didn't want to spend 60 bucks on rings that I won't be able to use if the pistons need replacing. I'm almost willing to "spare no expense" if it means that both the top & bottom are in harmony with one another. And if it means new rods, pistons and whatever else the bottom end needs, so be it. Im hoping with the oversized valves and 302 springs, along with the steel seats, I won't see the heavy carbon build up from the unleaded gas. I have a VP racing gas station down the street that sells non ethanol 93 octane gas and I expect that is the type of gas it will see in its future when this build is complete.if you leave the rings im place leave it be. If you change the rings there is a tool called a ridge reamer so the new top compression ring wont get damaged. If you see damage that looks like a piece of a piston ring broke off and got on top of the piston then it may rattle up and down in there and make marks. look around te circumference of that piston if you see any holes there near the edge above the top ring then I'd call the pistons done. you could see vertical scratches from where rings broke and scored the bore.

I think with the extent you are going , fitting oversized pistons and doing a rebore might be best beacuse it's dissapointing to spend money and see it burn oil.

I think you should talk to the mechanic. he may advise better on how far you can let thtings go . consider the cost of new oistons and the block removal and boring. but it's ultimately your decision how much to spend.

the cylinders dont wear evenly because of piston slap etc so you'll probably have more ridge where the wear is higher.

then you can choose to polish the crnk and put in new shells or to turn the crank and you can go on to replacing rod end bearings and such but that might not be necessary. if you still want ot spend more you can get the crank, pistons con rods and flywheel balanced and that will make it smoother especially if you are going to do performance mods.

my gut reaction is do it right and then youll be happy but its easy to just say go spend more money. I like the car it looks nice. you have to decide if you want this to be a "farmer rebuild" or basically a new engine and both make sense under certain conditions.

if you have the option to rebore then you may decide to jsut go the next size up or to go with larger pistons. some blocks have more meat. I increased the size of my volvo from 1800 to 2 liters by using larger pistons. others will know how big you can go with that ford without risking going intot he waterjacket. one school of though tis it probably made it this far and if you do rebuild it it may be good for the life of the car. If you wanted to keep the matching numbers and its somethign really special then you could opt to not remove more but it isnt; much more expensive to punch it out. if you can do that. It might be cheaper than other performance mods. that thing must have pretty good power with that engine. with my old volvo I wanted to end up with a bit more power to keep up in modern day traffic.. I did one wharre I just went from stock to the maximum stock oversize of .o30 and it did make a difference.

I guess if you were serious then you can have the block checked for cracks and things too. you might punch it out and find you want a different block ..

my choice would be to opt for the maximum oversize and then check the crank. If it's not bad I'd polish the crank myself and install new shells if it's bad then regrind the crank. I doubt youll blow up the bottom end but I thik chances are high that if you just do the top end it'll have more compression and burn oil because of the old rings and wear. you could ask the mechanic about the costs of balancing and his opinion. I feel that balancing is nice even if you aren't rodding it.. itll just run smoother at higher revs.

I had new bushings pressed intpo my rods and reamed them that's probably not necessary. when they did that they put the rods in a furnace to expand them before pressing in the new bushings. If you do want ot keep on doing performance mods than there is something to making the block really sound. If you just want it to drive and work than you dont need to go too crazy. It often becomes a personal challenge to do the best you can but then the cost can go up. my brother kept doing the top end on engines and it always seemed to work out a bit disappointing because then it would work a while then burn oil and he would loose interest in the vehicle and not want to open it all back up a second time.

Now if I can just get Jerry Cantrell from Schneider Cams to get back to me to tell me he finally got camshaft blanks in, maybe I can finally get that 264/274 cam made....

Attachments

Similar threads

All Small Six

200 6 rebuild steps

- Replies

- 121

- Views

- 14K

- Replies

- 13

- Views

- 2K

- Replies

- 42

- Views

- 7K

All Small Six

Early (1964) 200 ??

- Replies

- 12

- Views

- 2K

- Replies

- 45

- Views

- 10K