Hello Jack,

Yea, I have both pipeing of exhaust and coolant into the intake. I was wondering about the coolant as well. I would like to rid myself of both of them if possible. I just wasn't sure, not getting into the engine yet if the coolant was also piped into the head. I don't want to over heat the head. How bad do you suppose the vapor lock would be? It only gets down to freezing a couple weeks or maybe a month a year, and usually it only lasts for a couple of days at a time when it does. I would have thought vapor problems were more prevelant when the engine got hot, and atomization would improve since it's usually 80 degrees or more.

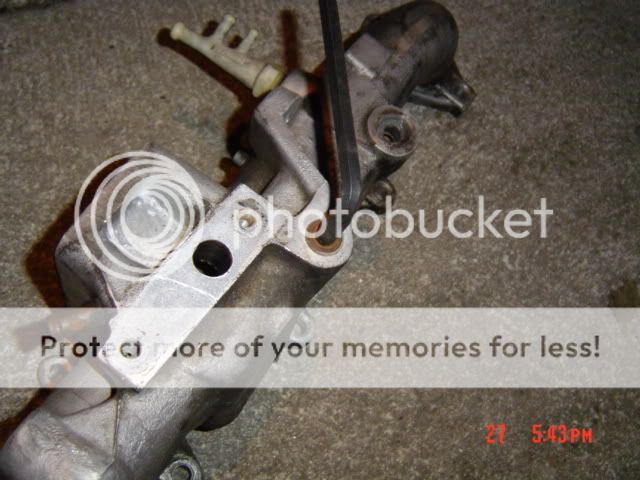

Also, like pcman, all the vacume lines, all three miles of it, on this engine aren't in the best of shape. There's another accesory next to the EGR valve (it's round and about the same size as the EGR valve with a couple of electrical connections) maybe a sensor of some sort, that I would also like to get rid of. I'm not sure what this does. It looks more like emmisions stuff than a needed sensor though.

I would like to just strip everything down to the bare neccesities. It looks like the only real vacume requirements would be (please correct me if I'm wrong) the advance for the distributor, the actuater(sp?) for the heater and what ever is required for the weber, which also has me baffeled.

Seems when I work the throttle that only one of the butterflies opens up. Does the other barrel work off of vacume or is there a linkage or method of making it mechanical?

So xtaxi,

Was the only difficult part in removing the EGR, making the plate that covers up it's hole?

Thanks for all the help guys. Getting this engine yesterday has got me pumped up. I'm real excited.

I won't ask any more questions for now but I will be needing the specifications for micing, miceing, mikeing, uh... I need to measure my crank journels and cylinders if anyone knows where I might find that info. Thanks guys,

Dave