You're just judging health by how much air leaks out of a sealed cylinder (top-center, valves closed). One part of the test is reading leak-down, and the other is determining where the leak(s) are. I do leak-down at 100 psi, as that makes all readings direct percent leakage, e.g., 93 psi is 7% leak-down.

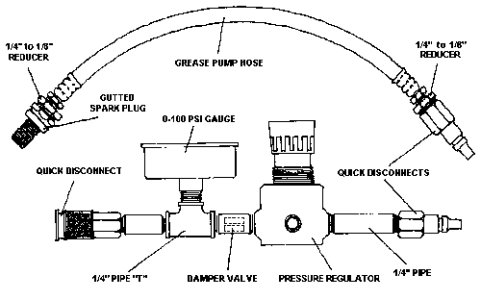

I use a home-made tool (below), and set pressure with my thumb over the open end, adjusting the compressor regulator until the leak-down gauge reads 100. I install in the cylinder that is at TDC compression stroke. I mark the damper in quarters so I'm sure it's right at TDC, or the air pressure will spin the crank around. That sucks if your wrench is still on the crank bolt.

Turn the air on and read the gauge.

Leakdown is judgmental for the type of build. A blueprinted and carefully-broken-in racing engine may have 1 to 3% leak-down. Performance engines in good shape 5 to 10%. Mom's car 10-20%. Beyond that is on it's way out the door, and while 30% might still limp to the grocery, it's on last legs and suffering badly. So for me, if it's towards the high-end for the type, I'll find what's leaking by sound.

Hissing heard at the oil filler cap are rings. From the carb is intake valve, and from the exhaust is exhaust valve. Stuff like that. A tired engine will be hissing everywhere.

Turn the crank 90° for the next cylinder in firing order. Test at part-stroke or BDC for comparative readings, such as 18% at TDC and 7% at BDC is a worn tapered bore. Bubbling in the radiator at TDC is probably a gasket, or at BDC is likely a crack. More on making and using one by Mike Nixon 25+ years ago here:

https://www.wheelhorseforum.com/topic/8183-leak-down-tester/

Here' is the DIY build in the article, bigger so you can see it. Note only one gauge is needed, as it is after the damper (restrictor), and pressure set closed-off. I simplified mine by using a Tee with 2 male ends and no regulator, using the one on the compressor. Leakdown testers are under $30 online these days if you're not the DIY type, and many auto parts stores loan them for free:

View attachment 21415

Leak-down is next, then decide the future from there on your terms.

Leak-down is next, then decide the future from there on your terms.