You have at least a 1978 or maybe even a 1979 200 Six Short Block with the High Mount Starter. Plus one of the best of the Large Log Heads stock these will out flow any of the earlier 1963 !/2 to 1968 200 small log heads even if they were fully ported with big valves installed. They have the larger 1 3/4 inch intake valves, a larger 1 3/4 inch Carb mounting hole, and are designed to run on the current unleaded fuels. That is one of a late model about 1978 up large Bell Housing with the Cable Clutch Type with its matching Throughout Bearing Arm for use with the Larger 1967 up Flat Flywheels and the 9 inch Clutch Assembly. These later models also used the Diagram type Clutches not sure on which transmission that Bell was used with might of been the Top Loader 3 speed with overdrive or else the T4 trans if it happens to be for a T4 it would then also work with a T5 5.0 Trans swap without needing an adapter plate. That's a nice Bell housing and you can use it with a Cable Clutch conversion kit (such as the good one that's made by Mustang Steve's) this would give you a much easier operating clutch pedal along with using the later Diagram Pressure Plate assembly. Since it was an Automatic be sure if your going with a Manual Trans that it has a Pilot Busing installed in the center hole of the Crankshaft. Looks to me like a excellent engine with lots of the great up grade parts. Best of luck.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

200ci I know this has probably been asked before. The 1966 200 CI 6 cyl is listed at 120 hp. I am thinking about replacing it with a 1979 200 CI,,,,,,but

- Thread starter myrod1937

- Start date

This applies only to 200ci

a quick ck of the 'free' archive I linked has ID methodology. I all ways ID what I have B4 wrking too much (ie ordering stuff).

I may B the only 1 here encouraging U to do so - a lill further. That might B more abt me than the vehicle. I want to B positive

abt every thing B4 me. (Tech IDs w/H2O Pump bolts, etc. C what they say).

I may B the only 1 here encouraging U to do so - a lill further. That might B more abt me than the vehicle. I want to B positive

abt every thing B4 me. (Tech IDs w/H2O Pump bolts, etc. C what they say).

My rod, you are looking at the exhaust manifold design code, the head design code is under the metal bracket, rear of the carb... The engine block design code is hidden but can be seen behind the exhaust pipe flange. Remember that these cast on codes are when the part was designed and not what year it is...You can find earlier design codes if they saw fit not to change it, but you will not find let us say a D7 code on a 66-year car because it was designed in 77 or for that model year...Well maybe on a Delorean.

Last edited:

Well, got back out to the engine. I guess it's for a 9" clutch, as it has the 2 bolt starter, which he said has only been used a couple times, but haven't pulled the bell yet to check it out. Since he started it a couple times in the wooden cradle he built, I assume it's the right flywheel (136 tooth?).

Attachments

yeah from a cursory glance I'd say 'late model' (77 - 80/83) but just see (swapables) like football ex, 'powered by ford vc. DSII ing, some smog-a-roochi stuff. Luv to C head/block castings (a ringer for a 200, stretch? might Ba 250?) 3.3, 4.1. (50 posts'n 3 pages later)/ Glad there's other members here as I could not place that transmis~

Ok, is there any other place I can look for the head casting (besides tearing the head off the block, and looking?)

The block number, on the outside is: D8BE (6015-GE) Why is that "not enough" to tell what block it is?

Someone said the head design code is under the metal bracket, rear of the carb..(since this is a “design code” will it mean anything?)

I pulled the bell housing shown and the number there is ElZR-6394-AA. (Not sure where it came from)

The fork for the "throw out bearing" has the number D9BC-7515 BA on it.

The flywheel attached to the engine (which I'm not sure where it came from) has 138 teeth (counted a dozen times, and couldn't come up with 136) not sure where it came from either.

(I just noticed that the Ford 4.0 V6 used a 138 tooth flywheel, not sure what I have)

The block number, on the outside is: D8BE (6015-GE) Why is that "not enough" to tell what block it is?

Someone said the head design code is under the metal bracket, rear of the carb..(since this is a “design code” will it mean anything?)

I pulled the bell housing shown and the number there is ElZR-6394-AA. (Not sure where it came from)

The fork for the "throw out bearing" has the number D9BC-7515 BA on it.

The flywheel attached to the engine (which I'm not sure where it came from) has 138 teeth (counted a dozen times, and couldn't come up with 136) not sure where it came from either.

(I just noticed that the Ford 4.0 V6 used a 138 tooth flywheel, not sure what I have)

Last edited:

I;m still encouraging use of the tech archive (I think U said U await delivery of the Handbook - this is free while U wait & a great companion. After reading both I knew what Qs to ask, how to ask them).

"...tearing the head off the block..."

I saw ur pic I believe. There is a part of the head that hasa 'log' (looks just like one) under the carb to pass's side of motor. There R 2 or 3 sets of castings on top of it in plain sight (If U have it exposed in frnt of U). No wrenchin involved - may B stretch oudda da way some components (any that obscure R that easy to shove asside). Facing the motor frm pass's side to the L on top of the log R Numbers/Ltrs. Read up to abt where carb is. I think there, a 2nd set to R of them is what Bubba writes of "2 screw-had looking embossments". Grab those too, bring to him. Eyes travel dwn some more to R & "Firing Order 536241" (OR SOMETHING). IF U FIND THE LATTER JUST GO IN REVERSE ORDER TO C. o0OP, SORRY 4 CAPS. Ur doing the research saves me from writting all this. Again:

HTH

"...Why is that "not enough" to tell what block it is?..." (Ur in chebby land now). I'm gunna close out for now. Will ck in w/U later~

"...tearing the head off the block..."

I saw ur pic I believe. There is a part of the head that hasa 'log' (looks just like one) under the carb to pass's side of motor. There R 2 or 3 sets of castings on top of it in plain sight (If U have it exposed in frnt of U). No wrenchin involved - may B stretch oudda da way some components (any that obscure R that easy to shove asside). Facing the motor frm pass's side to the L on top of the log R Numbers/Ltrs. Read up to abt where carb is. I think there, a 2nd set to R of them is what Bubba writes of "2 screw-had looking embossments". Grab those too, bring to him. Eyes travel dwn some more to R & "Firing Order 536241" (OR SOMETHING). IF U FIND THE LATTER JUST GO IN REVERSE ORDER TO C. o0OP, SORRY 4 CAPS. Ur doing the research saves me from writting all this. Again:

HTH

"...Why is that "not enough" to tell what block it is?..." (Ur in chebby land now). I'm gunna close out for now. Will ck in w/U later~

On the E1ZR-6394-AA Bell Housing Congratulations you got the best one.Ok, is there any other place I can look for the head casting (besides tearing the head off the block, and looking?)

The block number, on the outside is: D8BE (6015-GE) Why is that "not enough" to tell what block it is?

Someone said the head design code is under the metal bracket, rear of the carb..(since this is a “design code” will it mean anything?)

I pulled the bell housing shown and the number there is ElZR-6394-AA. (Not sure where it came from)

The fork for the "throw out bearing" has the number D9BC-7515 BA on it.

The flywheel attached to the engine (which I'm not sure where it came from) has 138 teeth (counted a dozen times, and couldn't come up with 136) not sure where it came from either.

(I just noticed that the Ford 4.0 V6 used a 138 tooth flywheel, not sure what I have)

That bell housing is the cable pull type and so is the clutch release arm so both of those work together. That Bell Housing is made for a Borg-Warner T-4, 4 speed transmission used on a 200 six (for a high mount starter block). They were used in the Fox chassis Mustangs, Mercury Capri‘s, the Fairmont's and probably in the Mercury Zephyr’s. The T-4 trans was a 4 speed (No Overdrive) they were made near the end of the 200 sixes production so the little six never had a T-5, 5 speed. But no worries the 5.0 V8 T-5 transmission will be a direct bolt on to the 6 cyl. T-4 bell without an adapter plate. You use the larger136 tooth 6 cyl. flat flywheel with its 9" dia. clutch.

Its been said by our recently deceased site member Mike Lavern that he was able to use the later 1990’s V6 bell housing and T5 on his 250 six i wonder if the V6 flywheel can fit on the inline six crankshaft it might or not I don’t know for sure. But being a V type of engine I don’t think it would work due to its imbalance unless it was re balanced for use on a 200 inline six, it would need to be a Zero imbalance. The 138 tooth count might be close enough to work in the bell.

Yes sadly has been several months ago now the info is all on his Budget 250 Build Thread.

If the 170 oil pump was a 1/4 drive it may be a shorter pump with a pickup that will hit the pan when used on a taller 1965 + 5/16" drive oil pump. I know a guy who had this problem. Use a 1965 + 200 oil pickup if the pan won't go all the way on with an early pickup and newer pump. You should be able to compare oil pump heights on Rockauto.Thank you Bubba, the Mustang I have was an early '65, with the 170 engine, WILL the oil pan and oil pickup still fit on this '79 200? Would you happen to have the part number for that larger bell, so I can hunt for it? As Xtcasy noted above, that dip stick tube, and oil pickup hole should already be there on the 1979 engine I'm going to look at, right. Thanks

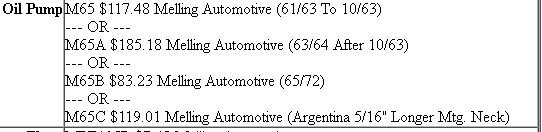

Hi 78_200_C4 and welcome to the Ford Six Forum! X2 Yes that's true that the 1/4 inch hex drive oil pumps were used used from 1960 until 1964 models. I have to wonder if the 1964 1/2 Mustang ever got the 1/4 drive oil pumps they all were technically sold as a 1965, But few people know that for the 1965 up 5/16 Hex drive Oil Pumps there are also two different heights too.

I don't know that US production oil pumps 65 and newer were 2 heights despite what may been seen in the Rockauto catalog. I know a 65 pump and pickup will bolt on a 78 200 no problem when changing to a 65 oil pan. Rockauto lists a MELLING M65C 5/16" taller pump for both a 1978 Ford 200 and a 1962 170. It can't fit both as one has a 1/4" drive the other has a 5/16" drive. I thought I read somewhere that taller pump was for South American made vehicles.Hi 78_200_C4 and welcome to the Ford Six Forum! X2 Yes that's true that the 1/4 inch hex drive oil pumps were used used from 1960 until 1964 models. I have to wonder if the 1964 1/2 Mustang ever got the 1/4 drive oil pumps they all were technically sold as a 1965, But few people know that for the 1965 up 5/16 Hex drive Oil Pumps there are also two different heights too.

Last edited:

Back in June of last year I was researching the Small Six oil pumps to see the differances the regular 170 / 200 M-65B Melling oil pump when used along with the ARP Main Studs are too close and need to be ground for clearance or a spacer made to drop the oil pump down some more. That's when I found out about the specs of the Melling M-65C oil pump it is suppose to have a 5/16 of an inch taller neck lenght over the M-65B both can be used in 170 & 200 sixes (years 1965 to 1983) both are standard pressure & volume oil pumps. If this is true then I believe that this extra 5/16 inch taller neck lenght would be just enough to help clear the ARP Main Studs without having to grind the bottom of the oil pumps body. As far as I know the block mounting bolt spacing of a 1/4 inch drive and a 5/16 oil pumps are both the same but what is different is that the early blocks from 1960 to 1964 which have a smaller .450 OD distributor shaft for the 1/4 inch hex drive plus the block pilot hole is also smaller to fit 1/4 inch drive center shaft of the distributor. The 1965 up engines have a larger .515 OD on the distributor shafts with a 5/16 hex drive in them, basicly only two parts were changed to be able to use the later M-65B oil pump versus the M-65A oil pump. The listings for both the M-65A and the M-65B oil pumps state that they are both regular lenght necks too.

Thank U for delivering what's hard news for me. Hope he got his rig done, that would B some satisfaction for him.Yes sadly has been several months ago now the info is all on his Budget 250 Build Thread.

"info... on... thread"

I read the umbolden thread titles (shows unread) and have not been back there. He (we) corresponded regularly for awhile on that thread, have not been there a good while. So I again appreciate this info.

Similar threads

- Replies

- 1

- Views

- 2K

- Replies

- 11

- Views

- 23K

- Replies

- 17

- Views

- 4K

- Replies

- 6

- Views

- 2K

- Replies

- 32

- Views

- 38K