Valleri66

New member

Hi All,

I've been searching around a bit and haven't found specifically what I'm looking for related to the stock timing curve for the 200 CID.

Engine Specs are essentially stock for me and specifically are:

500-550 [Idle - Automatic] - 12* (From Shop Manual)

1,200-1,600 - 20*

2,600-3,000 - 32*

I would ideally like to see what someone has for a timing table showing idle, tip-in, Cruise, and WOT.

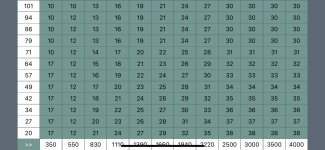

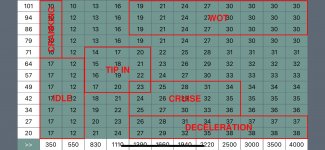

I've attached what I've plugged in for the Table Generator, its output as a timing table, and an annotation of the major points of timing per Progression Ignitions 'Tuning Guide' for reference.

The objective at this stage is driveability, with better than the stock performance from the improved carb and spark control/power.

I understand that every engine is different, so the primary discussion here is - all things equal - what is the stock curve?

Appreciate the collective experience!

I've been searching around a bit and haven't found specifically what I'm looking for related to the stock timing curve for the 200 CID.

Engine Specs are essentially stock for me and specifically are:

- 1966 200 CID

- Adjustable Rocker Arms (New Clay Smith Lifters and Chrome Moly Pushrods)

- C4 Automatic (2.83 Rear End)

- 1V Daytona Universal Carb

- Progression Ignition HEI with the ability to adjust timing via a table. (Yeah, I'm going to be the Guinea Pig)

- Maximum RPM-based Advance (Degrees)

- 'All-in' RPM

- Maximum Vaccum Advance (Degrees)

- Minimum Vaccum Advance at (Kpa/inHg)

- Maximum Vaccum Advance at (Kpa/inHg)

- Rev Limit

500-550 [Idle - Automatic] - 12* (From Shop Manual)

1,200-1,600 - 20*

2,600-3,000 - 32*

I would ideally like to see what someone has for a timing table showing idle, tip-in, Cruise, and WOT.

I've attached what I've plugged in for the Table Generator, its output as a timing table, and an annotation of the major points of timing per Progression Ignitions 'Tuning Guide' for reference.

The objective at this stage is driveability, with better than the stock performance from the improved carb and spark control/power.

I understand that every engine is different, so the primary discussion here is - all things equal - what is the stock curve?

Appreciate the collective experience!

Attachments

Last edited: