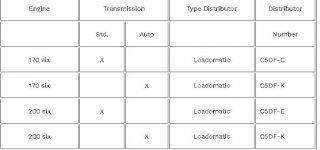

78_200_C4 - Thanks for all of the info. I tried finding a number on the distributor today but had no luck. I also took a look at the differential to find some type of ID, but it’s going to need a surface cleaning. The car did start out as a manual so there is a possibility that the distributor is the correct one. I know for sure that the Autolite 1100 carb I have is the correct one for a manual as it does not have the anti-stall dash pot that is found on the automatic models. I have been using it with the C4 despite that. As far as the differential is concerned, even if it is original to the car, it may have been for a different three speed transmission. I could be wrong, but I think that the 1965 inline six came with the 2.77 transmission not the 3.03 that I put in. Anyway, I’ll try to find out for sure. Thanks for alerting me to the gear ratio. I knew that if you put a V8 in you would have to change the gear ratio, but it did not occur to me that it would be necessary for this transmission change.

I feel that I got the valve train dialed in today. My initial cylinder compression was around 140 psi across the board. That is what I have been running for a while. The manual calls for a cylinder compression value of 155-195 psi. I have never had compression higher than than 140’s on this car since I got it. It was much lower when I first got.

When adjusting the pushrods, I used the method where you place cylinder one on TDC of the compression stroke and then adjust #1 Intake, #1 Exhaust, #2 Intake, #3 Exhaust, #4 Intake and # 5 Exhaust. Then, I rotated the engine until cylinder #6 was on TDC of the compression stroke. At that point I adjusted #2 Exhaust, #3 Intake, #4 Exhaust, #5 Intake, #6 Intake and #6 Exhaust. I tightened the adjuster until I could no longer rotate the pushrod with my fingers then I gave it about three quarters more of a turn. That extra turn at the end is where I have seen a lot of differences. Some say 1/4 turn or 1/2 turn. I even saw one individual suggest a full rotation. After I started the car back up, the engine ran terribly. It was very weak and shaking all over the place. I quickly ran another compression test. Cylinder #’s 1, 4 and 6 had zero compression! However, cylinders 2, 3 and 5 had a compression of 177, 177 and 180 psi respectively. Despite not having any compression on three of my cylinders, I was amazed to have compression value around 180 for the other three. I never had values that high. I wasn’t worried about the cylinders with no compression. I was pretty sure that the adjusters were over tightened on those cylinders keeping the valves from fully closing. I pulled the valve cover off again and backed off on the adjuster for cylinders 1, 4 and 6. I forget exactly how far I backed off. Either 1/4 or 1/2 turn. I tried the compression test again and cylinders 4 and 6 were now at 177 and 176 psi. Cylinder 1 was still at zero. I backed off cylinder one a little more and got its compression to 101 psi. After backing off a little more, cylinder 1’s compression went to 179 psi. I retested the compression of all the cylinders and got the following: #1-179, #2-177, #3-173, #4-174, #5-178, and #6-174. I have never had compression numbers on this engine that high before. Even better, when I ran the engine, it ran strong and there was no more of the clatter.

It is, though, idling very high. I have a handheld digital tachometer that sends a laser to a piece of tape placed on a rotating object. I placed the tape on the fan pulley. I wanted to place it on the crank pulley but couldn’t find a good spot. I’m guessing the fan pulley rotates in a 1:1 ratio with the crank (if not, please let me know). Anyway, the rpm reading that I was getting is 1380. That was with the engine warm. I know that is pretty high. My manual calls for an idle speed of 575 to 600 rpm. This is more than double. The next thing I need to do is readjust the cold and hot idle screw on the carburetor. I did not do it today because I am not sure of the proper procedure. I am going to do a little homework and hopefully get back out there tomorrow. Once again, thanks for all of the great information. Appreciate it.