MercuryMarc

Well-known member

I currently have my elect fan temp sensor switch tapped into a "T" fitting on the lower rad hose. I'd like to drill out the thermostat housing and tap a hole to mount the temp switch there.

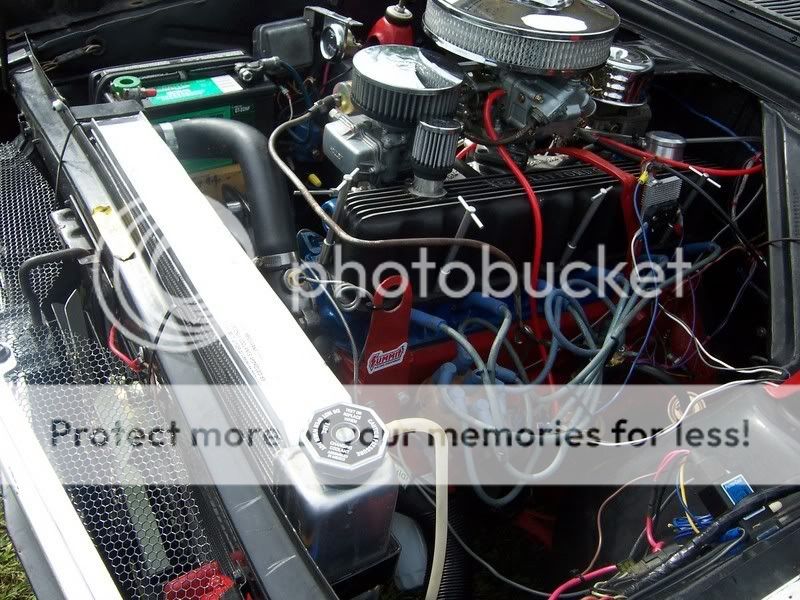

My thermostat housing has an area that looks like it was designed to be drilled and tapped:

Any suggestions on how to drill and tap the housing?

Thanks!

My thermostat housing has an area that looks like it was designed to be drilled and tapped:

Any suggestions on how to drill and tap the housing?

Thanks!