hucklburry

Well-known member

I bought Xflowecono's (Dave in TX) 76DA block with 82 alloy head, it sat for years, I thought I had oiled it enough before start up but bent 2 pushrods (hard to know until I got an exhaust on it, then started tuning carb, and finally did a compression test). Anyway, here is where I am at:

#2 intake seems the hydraulic lifter didn't pump up, I can spin the lifter but not getting it out too easy yet, working on that

#5 intake valve seems to be stuck closed, I am working on freeing it up (soaking now) hoping to not remove the head

This engine has like 3000 miles on a crow cam 14613, a bit of a "torq" cam, and crow recommends HT900 lifters, not a problem to source in the US

Crow recommends PR-917 push rods, which are 5/6" ball ends .080 wall, 9.7" long - mine aren't marked but that seems to be what it has (I will double check measurements) - I can get these in the US, and I can even get 5/6" .105 wall, is it worth it or better to just bend a push rod if there is a problem?

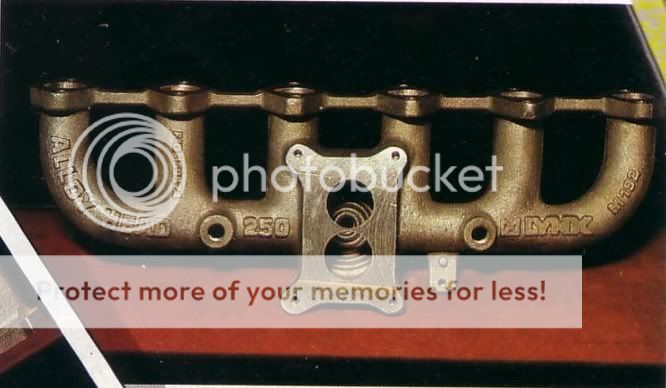

So I had pulled the valve cover and got the bent pushrods out, and out of 12 rocker arms, 2 are different. See the picture, I have two of the one on the top or left, and 10 of the one on the bottom or right. A google search looks like the one on the bottom or right references correctly to a stock crossflow rocker, part #181-1034, that I can get in the US also pretty easy. I don't know why it has 2 that are different??

Assuming I get the valve freed up, I am thinking of getting all new hydraulic lifters and pushrods, and at least 2 rocker arms. Perhaps some would recommend just going through the existing lifters cleaning etc as they were already used on this cam?

I've searched through the forum, I see roller rockers using a kit talked about, but that conversion kit from crane cams seems to be obsolete. This isn't a high reving engine with this cam (its installed in a 66 Bronco with a 3 speed on the column, 4.11 gears, and soon 33" tires), I wouldn't mind installing roller rocker arms, but I don't know the latest way to do that and what it does to my pushrods? Any current info would be appreciated.

To summarize - my big question is why the 2 odd ball rocker arms, and info on a roller rocker arm conversion (keeping the hydraulic lifters to fit the crow cam)

Thank you! --Jim

#2 intake seems the hydraulic lifter didn't pump up, I can spin the lifter but not getting it out too easy yet, working on that

#5 intake valve seems to be stuck closed, I am working on freeing it up (soaking now) hoping to not remove the head

This engine has like 3000 miles on a crow cam 14613, a bit of a "torq" cam, and crow recommends HT900 lifters, not a problem to source in the US

Crow recommends PR-917 push rods, which are 5/6" ball ends .080 wall, 9.7" long - mine aren't marked but that seems to be what it has (I will double check measurements) - I can get these in the US, and I can even get 5/6" .105 wall, is it worth it or better to just bend a push rod if there is a problem?

So I had pulled the valve cover and got the bent pushrods out, and out of 12 rocker arms, 2 are different. See the picture, I have two of the one on the top or left, and 10 of the one on the bottom or right. A google search looks like the one on the bottom or right references correctly to a stock crossflow rocker, part #181-1034, that I can get in the US also pretty easy. I don't know why it has 2 that are different??

Assuming I get the valve freed up, I am thinking of getting all new hydraulic lifters and pushrods, and at least 2 rocker arms. Perhaps some would recommend just going through the existing lifters cleaning etc as they were already used on this cam?

I've searched through the forum, I see roller rockers using a kit talked about, but that conversion kit from crane cams seems to be obsolete. This isn't a high reving engine with this cam (its installed in a 66 Bronco with a 3 speed on the column, 4.11 gears, and soon 33" tires), I wouldn't mind installing roller rocker arms, but I don't know the latest way to do that and what it does to my pushrods? Any current info would be appreciated.

To summarize - my big question is why the 2 odd ball rocker arms, and info on a roller rocker arm conversion (keeping the hydraulic lifters to fit the crow cam)

Thank you! --Jim