It was very easy to chop, I gave the head and a 12 pack of Sierra Nevada pale ale to my brother, and it came back chopped and milled about three hours later (we then drank most of the beer). He used a very large band saw and then a vertical mill to make it pretty.

This was mostly an information gathering experiment. I may not use this head for anything, depending on how the hex-log head looks. If I do use it, I think six runners to a plenum topped with a TBI unit would be just the ticket.

What I learned was:

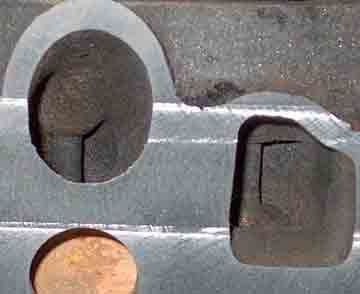

The C1 casting's intake runners are nearly round in cross section with an inner diameter of about 1 1/8". They look oval in that original pic, but that's because they run at a 40 degree angle to the plane of the cut.

There is enough meat left for freeze plugs.

The valve guide boss on the intake is huge.

There isn't one on the exhaust side, but there is a big ridge that should be smoothed out.

I'm going to do a later hex-log next to see the what the differences are. Also I think I'll have it cut it at a little bit of an angle toward the valve cover. More pics soon.

Rick(wrench)