Real quick, the forums new look is fantastic!

Yes! Many updates.

First real quick, I've obtained and have completed reconditioning an original 30 cubic inch Bourke engine, one of only 4 surviving examples left in the world. I've rebored the cylinders, got them nikasil coated, treated with RF85, and coated again in WS2. All other sliding surfaces have been treated with RF85 and coated in WS2 including the rings, piston, connecting rods and rod bushings, bearings, crankshaft, wrist pins, and etc. The counterweights and inside of the crankcase I cerakoted in cerakote microslick. The piston top and top of the combustion chamber I coated with cerakote piston coating, and the underside of piston and outside of the crankcase I cerakoted with high emissivity grey cerakote. The combustion chambers outside I covered with cerakote chrom to hold in heat to get the coolant up to operating temperature fast. All I need to do now is machine glow plug adapters to convert the engine into a HCCI engine instead of spark ignited. This has been quite the experience rebuilding a veritably ancient pre-WW2 era engine. It was quite the learning experience. It made me realize that people back in the day did a whole lot with a lot less available to them. For example, instead of snap rings to prevent the wrist pin from galling the cylinder wall, cylindrical top-hat shaped pieces of felt were pressed into the hollow ends of the wrist pins! And it worked! Reminds me of the time I took apart a really old truck tire and discovered an inner tube made from an animal intestine. I'll upload pictures of the rebuilt Bourke when I assemble it.

I've recently purchased an old van-normal piston grinder that I'll restore hopefully this year to grind the connecting rods and crankshaft and etc. So thats cool. Paid $300 for it. In theory it should produce a better finish at greater accuracy than a lathe, good for crankshaft journal surfaces and etc.

I still have yet to install my leblonde servoshift lathe because my rocket heater company (rocketheater.com) has been so busy I haven't been able to keep up with demand! I've just been making stoves all this year thus far. The good is that I have plenty of money to fund the engine project finally, the bad is that I've no time to pursue it!

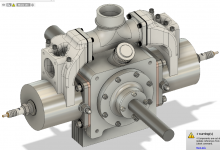

That being said, I have my 92cc design essentially completed and all blueprints made. All I need to do now is figure out whether I want to use an AMR300 roots supercharger or TVS V250 twin screw/whipple supercharger. I know that in most applications a twin screw is more efficient and I need to squeeze every ounce of power I can from this thing to break the 100cc land speed record, however the engine is so small I'll need to step down the RPM of the supercharger to be about 1/3 engine RPM. I've read in my old books that roots blowers are efficient at low RPM's and boost pressures, which is what I'm going for. However, a twin screw may still be more efficient at the end of the day. 0-5 PSI of boost is all I need, I just want to fill the cylinders to around atmospheric pressure, or a little more. I'll have to determine whether a twin screw or roots blower will be more efficient and better for this application. If you have any thoughts on the matter I'd love to hear them! As their names imply, the AMR300 pushes 300 cc's of air per revolution, and the TVS V250 pushes 250 CC's of air per revolution, whereas the engine hypothetically only needs 92cc's of air per revolution to fill the cylinders. To save energy I'm thinking about using more efficient roller chains instead of belts to drive the blower. I'm hoping that peak engine RPM will be no less than 22,000 RPM and as high as 30,000 RPM. I could also use a TVS V180 twin screw compressor that only outputs 180 cc's of air which will allow me to run the supercharger at 1/2 engine speed. Thoughts?