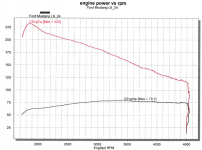

My stock cam has an advertised durstion of only 240°, and I want to stay with my C4 transmission with stock converter (stall at around 1800 rpm, car was on a chassis dyno):

That's why I'm trying to get a good understanding of the camshaft advance/retard: the plan is to put a cam between 260 and 267 and not more than 50 degree overlap into the engine to make it 1) more efficient and 2) stil be able to use the automatic transmission with stock converter.

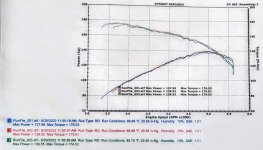

For example user "mad_science" postet his 250ci dyno results with the clay smith 274/274 (108 lsa) camshaft and made peak torque at around 2700rpm, that would be way too high for my converter.

[

https://fordsix.com/threads/built-250-dyno-results.84052/ ]

And I guess if the rule that 4° advance should get the peak torque rpm around 200 rpm lower, than I would have to advance the cam at least 20° (bad idea I would guess, valve clearences? valve events too much off from where they should be?)

And one more question I couldn't find an answer too: What factor has the most influence on the rpm the cam is used? Is it overlap? Is it the duration?

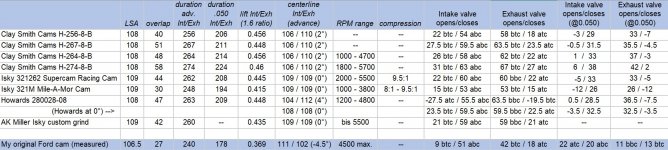

I made an overview of available 108-109 lsa camshafts for the Ford 200, but couldn't find rpm ranges for the 256 and 267 Clay Smith cams:

What confuses me a little is that the 264 Clay Smith (duration 264, overlap 48) and the 321262 Isky cam (duration 262, overlap 44) and even the Howard cam (duration 263, overlap 47) seem so similar in their specs, but differ so much in their rpm range!? Why is that?

As bubba said, the biggest factor in the power band is the .050" duration, not the advertised duration.

Secondly, where the power band begins relies on the .050" intake valves closing point.

All of this is relative to the engines displacement. The more displacement the engine has the lower and wider the torque curve will be.

Right now it looks like the cam makes it's best torque around the stall speed of the torque converter.

If you install an aftermarket cam, the torque peak will move upward in the power band and the engine will make more horsepower thanks to the improvements you made on the intake and exhaust systems.

It doesn't mean there will be less torque at 1800 rpms.

If the cam change is moderate it can make more torque at 1800 rpm but will continue to increase to its peak further up in rpm.

To start with "Mad Science" has a 250 engine which is 50 cu in. more than your engine.

Because your engine has 50 cubes less displacement it will actually move the torque peak up at least another 500 rpms with the same cam.

If you look at the stock 240 cam there is 62 degrees between the advertise and .050" duration.

The aftermarket cams have a lot less difference.

I'm thinking that you looked at the specs for the stock 200/250 cams and saw 256 degrees and thought that a 256 degree aftermarket cam was comparable. It is not. They will have a lot more .050" duration than the stock cams with the same advertised duration.

If you want to keep a low rpm torque band for a 200 six, use the smallest cam on you list.

That would be the Isky 321M.

These cams are used in the 144 to 250 cid sixes and because there is such a large variation in displacement there is no way to post an accurate rpm range for the cams unless the supplier wants to specify which engine they are referring to and even then it still won't be correct because most people are modifying the engines to varying degrees.

In other words, you CANNOT use the rpm range being shown with the cam specs.

The next important factor is the intake valves .050" closing point, and this is what is affected by moving the cam timing.

The stock cam you listed with the intake lobe center at 111 closes the intake valve at 20 degrees ABDC.

That is very early and is why it makes a lot of torque at 1800 rpm and below.

The Isky 321M cam's intake valve will close at 26 degrees ABDC which isn't far from the stock cam but the extra duration and valve lift will create a much longer and higher torque curve and a lot more horsepower.

Question: The 240 cam is shown as being the stock cam for the 170 but you have a 200?

How did your 200 end up the 240 cam instead of the 256?