This is my first build where I'm taking the time to degree the camshaft and I'm running into problems. I'm hoping someone can help me figure out what I'm doing wrong. Here's what I've done (twice now) and I continue to come up with the same numbers.

1) I'm using the JP Performance double roller timing chain that I got from Vintage Inlines. I lined up the camshaft (timing mark down) and crankshaft (0 degree up, no advance or retard) sprockets and installed the timing chain on the keyways.

2) I cranked the engine clockwise to get #1 piston coming up on compression stroke. Installed a piston stop strap and continued to bring the piston to the stop and wrote down the degree from the degree wheel. I then went counterclockwise and brought the piston back to the stop writing down the degree. Added them together and divided by two. TDC was at 24 degrees. I rotated the wheel to 24 degrees and then cranked the engine both directions to confirm 24 degrees was TDC. It was. Removed the strap and cranked the engine to show TDC (0) on the wheel and the piston at it's highest point of travel.

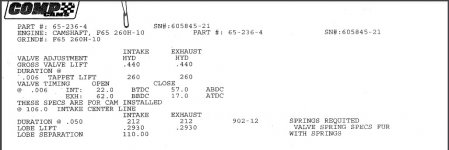

3) Dropped a solid lifter in the #1 intake lifter bore and set up my dial indicator and zeroed it out. Cranked the engine clockwise until intake lifter was at max lift. (Which was confirmed by cam card lobe lift of .293.). Zeroed out the dial gauge again and then went counterclockwise about .100 and then clockwise to .050 to get before max lift. The degree wheel reading was 51.5. I continued clockwise back to 0 then to .050 after max lift and got 137.5. That totaled 189, divided by two gets me to 94.5. My cam card has ICL at 106. I can't imagine being that far off, which is why I think I'm doing something wrong.

I've included cam card and a couple of photos. Any help would be appreciated. Thanks!

1) I'm using the JP Performance double roller timing chain that I got from Vintage Inlines. I lined up the camshaft (timing mark down) and crankshaft (0 degree up, no advance or retard) sprockets and installed the timing chain on the keyways.

2) I cranked the engine clockwise to get #1 piston coming up on compression stroke. Installed a piston stop strap and continued to bring the piston to the stop and wrote down the degree from the degree wheel. I then went counterclockwise and brought the piston back to the stop writing down the degree. Added them together and divided by two. TDC was at 24 degrees. I rotated the wheel to 24 degrees and then cranked the engine both directions to confirm 24 degrees was TDC. It was. Removed the strap and cranked the engine to show TDC (0) on the wheel and the piston at it's highest point of travel.

3) Dropped a solid lifter in the #1 intake lifter bore and set up my dial indicator and zeroed it out. Cranked the engine clockwise until intake lifter was at max lift. (Which was confirmed by cam card lobe lift of .293.). Zeroed out the dial gauge again and then went counterclockwise about .100 and then clockwise to .050 to get before max lift. The degree wheel reading was 51.5. I continued clockwise back to 0 then to .050 after max lift and got 137.5. That totaled 189, divided by two gets me to 94.5. My cam card has ICL at 106. I can't imagine being that far off, which is why I think I'm doing something wrong.

I've included cam card and a couple of photos. Any help would be appreciated. Thanks!