You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six 68 small log head porting [ including final DYNO RESULTS ]

- Thread starter clochard68

- Start date

This relates to all small sixes

A little update on the progress:

It's been a little over 900 miles now since the cam break in and the 200 runs good except for the head gasket that leaks from time to time (project for the winter again!). So I thought it's time for the second dyno test to see how much gains the small log head is capable of. It is scheduled on saturday, and I will post the results with the comparison of the first dyno test (it's also on page 1) and a summary of all modifications.

In the meantime I wanted to share a picture of my wife from 3 weeks ago on our wedding day "working" on the 200

So I wish everyone also a happy 2024 and may all projects go as planned!

It's been a little over 900 miles now since the cam break in and the 200 runs good except for the head gasket that leaks from time to time (project for the winter again!). So I thought it's time for the second dyno test to see how much gains the small log head is capable of. It is scheduled on saturday, and I will post the results with the comparison of the first dyno test (it's also on page 1) and a summary of all modifications.

In the meantime I wanted to share a picture of my wife from 3 weeks ago on our wedding day "working" on the 200

So I wish everyone also a happy 2024 and may all projects go as planned!

that’s great. Like to see a 1/4 drive ratchet w/3/8th socket in her left hand lol

Hopefully the dyno runs are on the same machine, all other factors are consistent but

“...to see how much gains the small log head is capable of...” what’s measured. Let us

know how ya do.

Good Luck !

Hopefully the dyno runs are on the same machine, all other factors are consistent but

“...to see how much gains the small log head is capable of...” what’s measured. Let us

know how ya do.

Good Luck !

Thanks Chad!

Yes the dyno is exactly the same as the last time

Yes the dyno is exactly the same as the last time

please delete

Last edited:

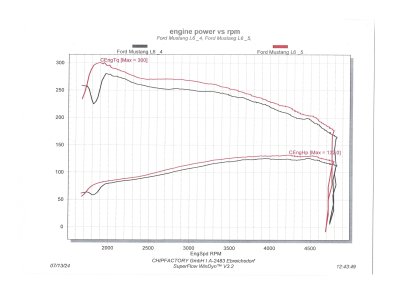

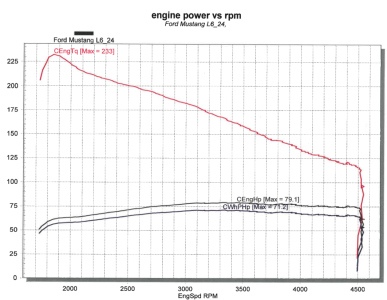

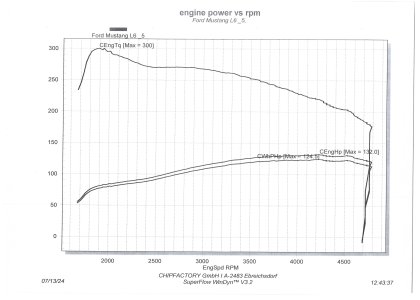

So we were at the same dyno today like we were way back in october 2020 and made 2 pulls. One with my personally designed velocity stack for the weber 32/36 (that was the worse pull) and one without the velocity stack. So my idea of a velocity stack inside a stock air cleaner didn't work unfortunately, maybe it is to close to the top lid and chokes the carburetor a little...

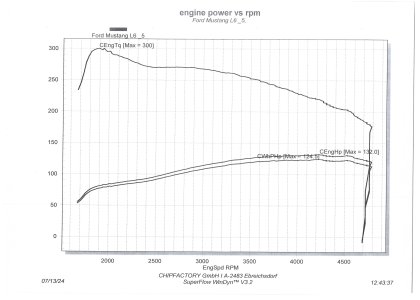

The results exceeded my expectations to be honest.

The best pull made 124.5 hp at around 4200 rpm at the wheels with a max of 300 Nm (=221 ft lbs). That is a gain of 53.3 hp to my baseline from almost 4 years ago.

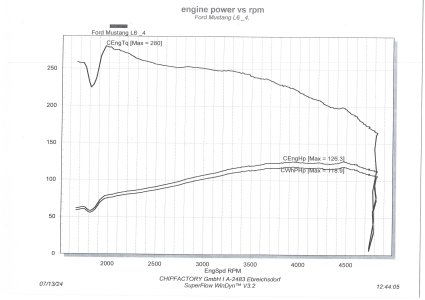

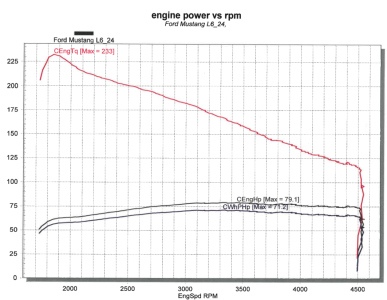

Here is the baseline pull from 2020. Ignition, carburetor and valves where not in best shape. The engine wouldn't rev over 4500 rpm, I guess because of valve float:

The specs were:

dished pistons, 0.030 over

stock hydraulic camshaft 240 advertised duration, 4.5° retarded (measured)

Holley 1940 one barrel carburetor

calculated CR 8.49:1, calculated DCR 7.48:1

stock 1-3/4" exhaust with stock manifold

Here is the dyno sheet from the best pull today, that was without the velocity stack. With the new beehive valve springs 5000 rpm was no problem:

The specs as of now:

dished pistons, 0.030 over

Isky Mile-A-Mor hydraulic camshaft 248 advertised duration, installed straight up (measured)

Weber 32/36 progressive two barrel carburetor (little work done to it, page 7) with opened up and shaped 2 to 1 adapter

calculated CR 9.08:1, calculated DCR 7.95:1

2.5" single exhaust with Flowmaster 50 eries muffler

exhaust port divider

Pacemaker longtube headers

cold air intake from grille, WIX paper air filter

ported small log head, backcut on intake valves (all valves standard size)

1.65 roller tip shaft rockers and beehive valve springs

HEI ignition, recurved from @wsa111

MSD street fire coil with low resistance bushing and MSD spark plug wires

NGK WR5 spark plugs, gap 0.055"

2 row aluminum radiator and high flow water pump

And here are some videos of the pulls:

The results exceeded my expectations to be honest.

The best pull made 124.5 hp at around 4200 rpm at the wheels with a max of 300 Nm (=221 ft lbs). That is a gain of 53.3 hp to my baseline from almost 4 years ago.

Here is the baseline pull from 2020. Ignition, carburetor and valves where not in best shape. The engine wouldn't rev over 4500 rpm, I guess because of valve float:

The specs were:

dished pistons, 0.030 over

stock hydraulic camshaft 240 advertised duration, 4.5° retarded (measured)

Holley 1940 one barrel carburetor

calculated CR 8.49:1, calculated DCR 7.48:1

stock 1-3/4" exhaust with stock manifold

Here is the dyno sheet from the best pull today, that was without the velocity stack. With the new beehive valve springs 5000 rpm was no problem:

The specs as of now:

dished pistons, 0.030 over

Isky Mile-A-Mor hydraulic camshaft 248 advertised duration, installed straight up (measured)

Weber 32/36 progressive two barrel carburetor (little work done to it, page 7) with opened up and shaped 2 to 1 adapter

calculated CR 9.08:1, calculated DCR 7.95:1

2.5" single exhaust with Flowmaster 50 eries muffler

exhaust port divider

Pacemaker longtube headers

cold air intake from grille, WIX paper air filter

ported small log head, backcut on intake valves (all valves standard size)

1.65 roller tip shaft rockers and beehive valve springs

HEI ignition, recurved from @wsa111

MSD street fire coil with low resistance bushing and MSD spark plug wires

NGK WR5 spark plugs, gap 0.055"

2 row aluminum radiator and high flow water pump

And here are some videos of the pulls:

Last edited:

PSIG

Famous Member

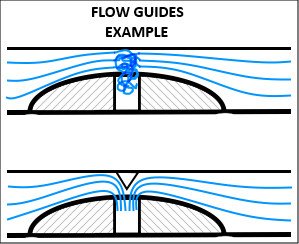

Perhaps it still could. By adding the hump, you smoothly directed air into a direct head-on collision with random turbulence. Adding a top-flow guide could direct the air down, instead of into collision chaos. OK, not as smooth as my quickie diagramAnd here is the comparison of the two pulls from today, the red one is without the velocity stack I worked so hard onI could have sworn it improved the performance, but the dyno numbers say otherwise...

This concept comes from the testing of X-Stream filter housing tops, where adding the extra filter area didn't help flow, and often hurt it on 4V carbs. The solution was a short 'funnel' insert on the stud to block the confusion and guide it into the carb inlet. Bingo, flow jumped. Your base has smooth flow guiding, but the top does not, in order to finish guiding into the inlet. That's my hypothesis, and I'm sticking to it.

Re-testing without a dyno can be found with diagnostic performance measurements (including changes in AFRs), indicating improvement or not. There is a lot we can do to gather data without a dyno. Sure, a dyno is quick and specific, but creative street testing can give answers as well.

Last edited:

clochard68- congrats on the significant improvements! Impressive.

PSIG is right about the shape of the air entering the airhorn. Before computers to assist the efforts, in the 1960's the designers of the Quadrajet got max dyno results with the factory drop-base air filter housing with the paper element installed. (It was a high performance dual snorkel model, BB Chevy). 15 more HP than no filter housing at all, and 10 more than the filter housing with no element in it. The smooth upward curve of the filter base gave the air a curved arc which smoothed and concentrated it just above the airhorn. No element in the housing, the air was streaming in directly from the snorkels and was more turbulent.

Reducing turbulence at the carb entrance assists mixture balance, and this can be as much of a power factor as smoother air=more air. Turbulence or vacuum on the fuel bowl vent that's in the airhorn changes the head pressure on the fuel in the bowl which changes the pressure of the fuel entering the jet(s). A restricted intake (vacuum at the vent tube mouth) causes the carb to go lean. Turbulence at the vent has the same effect. When I straightened out the air into an Edelbrock with a 3" tall stack between the air filter and carb, there was a slight but noticeable performance increase, and the heavy throttle mixture enriched 8% with no jet changes. The E'brock has a terrible shape where the air enters, and causing all the air to come straight down into the carb gained power and mixture stability.

The net effect of turbulence varies with every carb design, but regardless, tumbling air entering the carb hurts performance.

PSIG is right about the shape of the air entering the airhorn. Before computers to assist the efforts, in the 1960's the designers of the Quadrajet got max dyno results with the factory drop-base air filter housing with the paper element installed. (It was a high performance dual snorkel model, BB Chevy). 15 more HP than no filter housing at all, and 10 more than the filter housing with no element in it. The smooth upward curve of the filter base gave the air a curved arc which smoothed and concentrated it just above the airhorn. No element in the housing, the air was streaming in directly from the snorkels and was more turbulent.

Reducing turbulence at the carb entrance assists mixture balance, and this can be as much of a power factor as smoother air=more air. Turbulence or vacuum on the fuel bowl vent that's in the airhorn changes the head pressure on the fuel in the bowl which changes the pressure of the fuel entering the jet(s). A restricted intake (vacuum at the vent tube mouth) causes the carb to go lean. Turbulence at the vent has the same effect. When I straightened out the air into an Edelbrock with a 3" tall stack between the air filter and carb, there was a slight but noticeable performance increase, and the heavy throttle mixture enriched 8% with no jet changes. The E'brock has a terrible shape where the air enters, and causing all the air to come straight down into the carb gained power and mixture stability.

The net effect of turbulence varies with every carb design, but regardless, tumbling air entering the carb hurts performance.

Thanks Frank!

As you and PSIG mentioned the area above the velocity stack might be the problem. The inlets of the carb are off-center in the air cleaner housing and therefore the lid sits in an angle above the openings, it's far from ideal...

For now I will leave the velocity stack off, and maybe somewhere in the future print an adapter for the lid to straighten the air flow like PSIG has pictured above.

Would require another dyno test to verify that it works also

As you and PSIG mentioned the area above the velocity stack might be the problem. The inlets of the carb are off-center in the air cleaner housing and therefore the lid sits in an angle above the openings, it's far from ideal...

For now I will leave the velocity stack off, and maybe somewhere in the future print an adapter for the lid to straighten the air flow like PSIG has pictured above.

Would require another dyno test to verify that it works also

JoeCrozier

Well-known member

Sorry to dig up an old thread, but regarding your 3d printed velocity stack, have you considered redoing it with a different shape? I've seen a lot that look like this:

And I've seen some pretty cool 'interactive' dyno videos where the person would literally lift the stack off and put it back on and you could see the hp change in real time. I feel like its gotta work.

And for the price of 3d printing filament (i.e. cheap), why not?

Lastly, awesome thread. I have an old 144 with a small log that I've just been tinkering with to see if I could even rebuild an engine and you opened my mind to all sorts of possibilities.

And I've seen some pretty cool 'interactive' dyno videos where the person would literally lift the stack off and put it back on and you could see the hp change in real time. I feel like its gotta work.

And for the price of 3d printing filament (i.e. cheap), why not?

Lastly, awesome thread. I have an old 144 with a small log that I've just been tinkering with to see if I could even rebuild an engine and you opened my mind to all sorts of possibilities.

par for "ol thread”.

We revisit M U C H older threads

w/o objection. My add? that’s what the

site is all about, an archive of ideas, a visit site

of ol dudes, all for questions, ideas and comments.

Tha Cutts 3D looks like a fit here? Top row, third in from L?

We revisit M U C H older threads

w/o objection. My add? that’s what the

site is all about, an archive of ideas, a visit site

of ol dudes, all for questions, ideas and comments.

Tha Cutts 3D looks like a fit here? Top row, third in from L?

JoeCrozier

Well-known member

Definitely. There's probably something else on printables as well (4th one in). I like the interface on printables as well, easy to search.par for "ol thread”.

We revisit M U C H older threads

w/o objection. My add? that’s what the

site is all about, an archive of ideas, a visit site

of ol dudes, all for questions, ideas and comments.

Tha Cutts 3D looks like a fit here? Top row, third in from L?

I am obviously a total beginner to engines and inline 6's, but if anyone has any questions about 3d printing let me know. My previous job 'in real life' was 3d printing surgical models at a hospital and i've used everything from the $200 printer in my basement up to a quarter million dollar behemoth.

Its crazy how far 3d printing has come in recent years as well. All sorts of high tech filaments that can be used in functional, final product pieces. Many of which that can be printed at home by the DIY enthusiast. I've seen a bunch of intake manifolds and car interior/exterior pieces printed, and with the advent of cheaper metal 3d printing we're even beginning to see things like connecting rods and pistons being developed. Cool stuff

Hi Joe,

I do run it at the moment with an commercial aluminum velocity stack (as pictured). After giving it more thought, I think also a big mistake I made with my design is that it covers partly the opening for the air corrector jets, so at high engine speeds there is a restriction.

I will be posting again in autumn, I did upgrade to a Weber 38/38 (must say, big improvement in torque and power) and I got bigger SI-valves for the intakes, but not installed yet...

Plan is to upgrade to the bigger valves (throat size will stay the same though!) to have a bigger curtain area and hopefully some intake flow improvement at low lift, and then test the bigger valves with weber 38/38 combo again on the dyno.

Will post the results here in the thread.

Your 144 with the small log will perform great, your relation of plenum volume to displacemet is even better than with a 200ci engine! Have fun with the rebuild, I am interested to see your progress!

Regards, Martin

I do run it at the moment with an commercial aluminum velocity stack (as pictured). After giving it more thought, I think also a big mistake I made with my design is that it covers partly the opening for the air corrector jets, so at high engine speeds there is a restriction.

I will be posting again in autumn, I did upgrade to a Weber 38/38 (must say, big improvement in torque and power) and I got bigger SI-valves for the intakes, but not installed yet...

Plan is to upgrade to the bigger valves (throat size will stay the same though!) to have a bigger curtain area and hopefully some intake flow improvement at low lift, and then test the bigger valves with weber 38/38 combo again on the dyno.

Will post the results here in the thread.

Your 144 with the small log will perform great, your relation of plenum volume to displacemet is even better than with a 200ci engine! Have fun with the rebuild, I am interested to see your progress!

Regards, Martin

JoeCrozier

Well-known member

Can’t wait to see the new dyno results

What size intake valve do you plan on using?

Guy dwn da st. hasa Maker’s Shop (might B wrong word). He’s willing to invite guys in to play w/the mo chene. A sorta club. Odd hrs (not much) and other strings attached. I’d lub ta visit ! Jealousa Joe. 8^ )Definitely. There's probably something else on printables as well (4th one in). I like the interface on printables as well, easy to search.

I am obviously a total beginner to engines and inline 6's, but if anyone has any questions about 3d printing let me know. My previous job 'in real life' was 3d printing surgical models at a hospital and i've used everything from the $200 printer in my basement up to a quarter million dollar behemoth.

Its crazy how far 3d printing has come in recent years as well. All sorts of high tech filaments that can be used in functional, final product pieces. Many of which that can be printed at home by the DIY enthusiast. I've seen a bunch of intake manifolds and car interior/exterior pieces printed, and with the advent of cheaper metal 3d printing we're even beginning to see things like connecting rods and pistons being developed. Cool stuff

@drag-200stang

I got the 1.76 SI-valves for the intake side.

I am keeping the current throat size, that will shift the throat to valve diameter percentage from ~91% to ~86% (if I remember correctly).

My goal is to get better cylinder filling at low lift (my max lift with my cam/rocker combination is 0.415")

I got the 1.76 SI-valves for the intake side.

I am keeping the current throat size, that will shift the throat to valve diameter percentage from ~91% to ~86% (if I remember correctly).

My goal is to get better cylinder filling at low lift (my max lift with my cam/rocker combination is 0.415")

Similar threads

All Small Six

Winter Project: Better breathing with a large log

- Replies

- 24

- Views

- 731

- Replies

- 27

- Views

- 2K

- Replies

- 10

- Views

- 2K

- Replies

- 29

- Views

- 1K

- Replies

- 22

- Views

- 1K