Another side project I've been working on for a while is a mount for the coil packs near the spark plugs. My original thought way back when was a custom inspection cover with screw bosses machined in and running the coils "flat" against the inspection cover, but the price of material alone made that a nonstarter, not even considering machining costs. Then I thought, what about welding bosses to the (aussiespeed cast aluminum) inspection cover or valve cover, which could work, but I'm not a welder so again a bit of a non starter. Plus, I already had the valve cover in wrinkle black, and didn't want to grind it off.

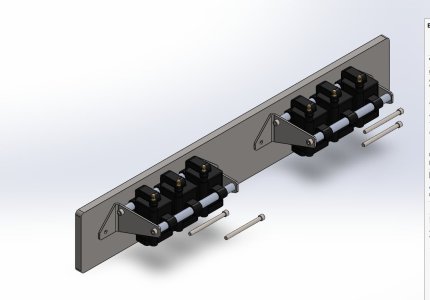

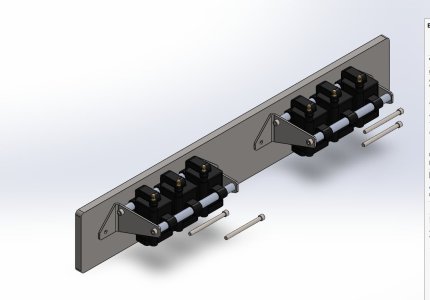

So I thought, you know what is cheap and easy is bent sheet metal parts, and I still have the inspection cover bolt holes to work with. And here we are - The inspection cover is symmetric around the middle, so whatever worked for the front stack should also work for the rear stack. This meant just 2 unique brackets, with similar designs, but the rearward one being a bit longer. Spacers are 3/4" at each end and 1.5" in the middle, and the whole thing goes together with 2 pieces of 1/4" all thread rod.

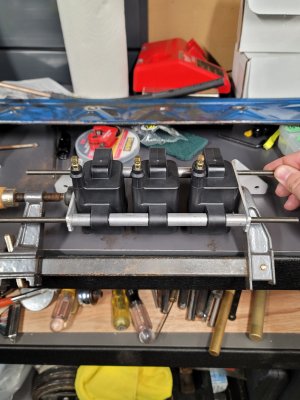

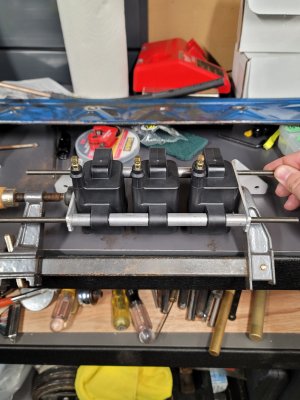

Shoot off the brackets to sendcutsend, and a donation to McMaster Carr for the spacers and rod, and a week later I was able to test fit.

Add in the matching aussiespeed side plate (after 3 years lol), and here we are.

Truthfully, the vertical offset was a bit arbitrary. When designing in Solidworks I assumed the inspection cover was completely vertical, so I offset up to make sure there would be room to the injector harness underneath, but it ended up being less of a problem than I thought because the cover angles inwards a bit, splaying the plugs out. And I biased the packs toward the front (at least, in the front stack) to make sure there'd be enough room for the distributor.

At any rate, I'm pretty happy with how these have turned out. Didn't look 100% like I imagined (sticks out more than I thought it would), but it keeps the plug wires short and the coils tidy.