Frank, thanks so much for your post. Wish I could have tried your advice earlier this week, but I just got over my knee's steroid shots. These are not fun.

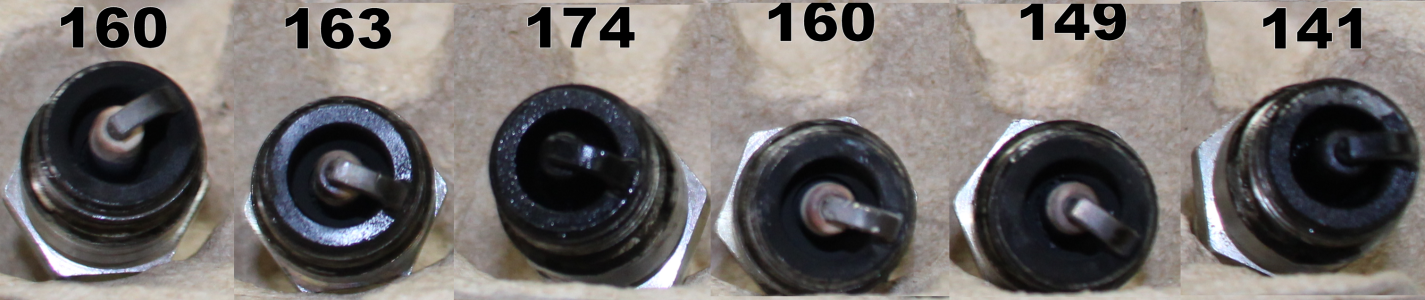

Before continuing, I cleaned and regapped all six plugs and spent an hour resetting the points to as near perfect as I can get them (points gap was on the high side). Following a different thread, I also checked my harmonic balancer by turning the engine over by hand until #1 was exact top - timing point was exactly at zero, so spun balancer is not my issue.

Following your directions, I propped the throttle about 25% and set the thermostat so it was just barely closed and easy to open. I guess I need to completely ignore the marking on the thermostat. Following your directions, the thermostat index ended up about 90º looser (i.e., it's pointing straight starboard now). I had the idle set way high to keep the engine running (due to my miss on cylinder #6). Car started immediately, ran very rough, and clattered loudly (just like it did before). I ran it at high RPM until it warmed up. Seems like it burnt away the stuff in #6 once it got hot because now the clatter stopped, it's running pretty smooth, and the idle went way up. Even though warmed up, it was still on the fast idle screw. How hot is it supposed to get before it drops off fast idle to the regular idle setting?

More importantly, do you think my OCD-ing the points gap and your procedure for thermostat setting actually fixed my super-rich condition that was fouling my plugs and killing my MPG?

After warmup I hooked up my old Sears 'Engine Analyzer'. Despite my careful points setting, it shows 25.5º at 680 RPM. Spec says dwell should be 35º to 38º at idle. There's no way I was that far off. Not sure I should trust the meter now or can something else be wrong to get a different dwell angle (when running) even when point gap is correct (with engine off)?