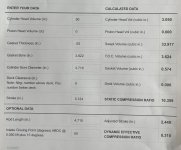

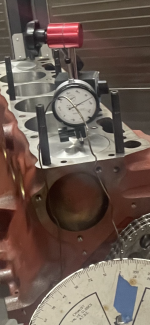

Just some info on my own behalf  , I kinda inherited this engine. The bottom end was together and the cam was in when I got it. I was not involved in any of the planning on cam selection, compression or machine work. The head work was done, no springs or push rods and tells terra rockers in a box. I think the motor had set for 2 to 3 years. The extent of what the have done is, plastiguage the mains and rods, had the head freshened up, seats, intake runners and face touched up removing surface rust. I have selected the springs to match to cam requirements, smith bros push rods, timed the cam with double roller chain, plugged the oil passage to the head in the block, put groves in the two lifters over the distributor gear, drilled a .030 hole in oil plug behind cam chain. Re- worked my oil slinger to clear the double roller(torch and tie rod tools and a hammer). CC the head to see where it is at, installed the rockers/pushrods, timing cover, modified oil pump to clear main studs. The head is : DODE-6090 modified for two barrel carb, 1.75 SI intake valve, 1.5 SI valves. Silvolight flat top pistons. The deck was milled to 0 piston height. 50-51 cc chambers. Compression is figured at 10.3 static and 8.3 dynamic. I have jet coated headers, and DUI dizzy and wires ( will be re-curved by Bill

, I kinda inherited this engine. The bottom end was together and the cam was in when I got it. I was not involved in any of the planning on cam selection, compression or machine work. The head work was done, no springs or push rods and tells terra rockers in a box. I think the motor had set for 2 to 3 years. The extent of what the have done is, plastiguage the mains and rods, had the head freshened up, seats, intake runners and face touched up removing surface rust. I have selected the springs to match to cam requirements, smith bros push rods, timed the cam with double roller chain, plugged the oil passage to the head in the block, put groves in the two lifters over the distributor gear, drilled a .030 hole in oil plug behind cam chain. Re- worked my oil slinger to clear the double roller(torch and tie rod tools and a hammer). CC the head to see where it is at, installed the rockers/pushrods, timing cover, modified oil pump to clear main studs. The head is : DODE-6090 modified for two barrel carb, 1.75 SI intake valve, 1.5 SI valves. Silvolight flat top pistons. The deck was milled to 0 piston height. 50-51 cc chambers. Compression is figured at 10.3 static and 8.3 dynamic. I have jet coated headers, and DUI dizzy and wires ( will be re-curved by Bill ) and I have a Holley 2300 350 cfm carb

) and I have a Holley 2300 350 cfm carb

This is why I am now concerned about what I have. I really don’t want to get into mixing additives to my gas. I just want to run ethanol free. I can get 91oct locally. I just don’t know if I need to maybe open up the chambers to get my compression down a little. Or maybe it will be ok to just adjust timing as needed

I have an assoc degree in automotive technology so I have a basic understanding and knowledge of how engines work. As they say, enough to be dangerous . But the knowledge and understanding of engine building and engine engineering and how they affect the end product is past me. I even understand the cam terms and what they are, but to know how different variables affect The end performance is beyond my knowledge. I am impressed by reading posts and the knowledge of members here is impressive.

. But the knowledge and understanding of engine building and engine engineering and how they affect the end product is past me. I even understand the cam terms and what they are, but to know how different variables affect The end performance is beyond my knowledge. I am impressed by reading posts and the knowledge of members here is impressive.

So please be gentle on me if this build hasn’t been done properly and in order. I am just trying to make sure I have it sorted as much as possible.

And again, my cam specs:

This is why I am now concerned about what I have. I really don’t want to get into mixing additives to my gas. I just want to run ethanol free. I can get 91oct locally. I just don’t know if I need to maybe open up the chambers to get my compression down a little. Or maybe it will be ok to just adjust timing as needed

I have an assoc degree in automotive technology so I have a basic understanding and knowledge of how engines work. As they say, enough to be dangerous

So please be gentle on me if this build hasn’t been done properly and in order. I am just trying to make sure I have it sorted as much as possible.

And again, my cam specs: