You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

All Small Six i6 250

- Thread starter jaymac2012

- Start date

-

- Tags

- 250 cylinder head

This relates to all small sixes

jaymac2012

Active member

It's amazing how this 250 is much more of a puzzle than my current 302. I've found the first expensive part that I may need to break down and buy: Crank pulley. I haven't been able to locate any new ones except on NPD for $245. The only other thing I've found is the harmonic damper repair sleeve. Does anyone have experience with this? I found some kind of repair kit on Napa with a rubber o-ring, but unsure of its use.

The rubber around my original damper is definitely old, hard and chipping. When I removed it, I got the gear puller ready, but didn't need it because it almost fell out. Is this what the repair sleeve does? Firms up the old harmonic damper into the block?

Also, how much cross model compatibility is there with parts for a 250? I keep pulling up Chevy 250s and Jeeps with my google searches.

The rubber around my original damper is definitely old, hard and chipping. When I removed it, I got the gear puller ready, but didn't need it because it almost fell out. Is this what the repair sleeve does? Firms up the old harmonic damper into the block?

Also, how much cross model compatibility is there with parts for a 250? I keep pulling up Chevy 250s and Jeeps with my google searches.

... isn't a damper repair sleeve a thin sleeve repair for scored crank seal ?, used to call them 'speedy seals'..

. typical

;

www.oreillyauto.com

.

www.oreillyauto.com

.

'typical 170-200/250 'Balancer's

.

.

.

...'have a 'speedy seal' on the HiPo 170 Falcon

.

.

.

untypical 250 W / 'Fisher' Balancer

.

.

.  .

.

.

have fun

. typical

;

Harmonic Balancer Repair Sleeve | O'Reilly Auto Parts

Shop for the best Harmonic Balancer Repair Sleeve for your vehicle, and you can place your order online and pick up for free at your local O'Reilly Auto Parts.

'typical 170-200/250 'Balancer's

.

.

.

...'have a 'speedy seal' on the HiPo 170 Falcon

.

.

.

untypical 250 W / 'Fisher' Balancer

.

.

.  .

.

.

have fun

Last edited:

Send yours to this company for full overhaul. Several big6 guys on the forum have had their original rebuilt here, and the quality is A+. Small operation, the guy takes pride in his work.It's amazing how this 250 is much more of a puzzle than my current 302. I've found the first expensive part that I may need to break down and buy: Crank pulley. I haven't been able to locate any new ones except on NPD for $245. The only other thing I've found is the harmonic damper repair sleeve. Does anyone have experience with this? I found some kind of repair kit on Napa with a rubber o-ring, but unsure of its use.

The rubber around my original damper is definitely old, hard and chipping. When I removed it, I got the gear puller ready, but didn't need it because it almost fell out. Is this what the repair sleeve does? Firms up the old harmonic damper into the block?

Also, how much cross model compatibility is there with parts for a 250? I keep pulling up Chevy 250s and Jeeps with my google searches.

DamperDoctor

The #1 source for new and rebuilt harmonic balancers, Dampers for internal combustion engines. vibration dampers rebuilt to OEM specs. replacement harmonic vibration balancers a

www.damperdoctor.com

www.damperdoctor.com

jaymac2012

Active member

Got quoted $175 for rebuilding a crank pulley. Doesn't look as though I have much choice since I can't find a new one anywhere. Not sure of the dampers for the 170 or 200 will fit a 250. Weird that there aren't any new dampers out there.

That's a deal, if Damper DR is doing it. The rebuilt units are superior to the overseas new ones available, there has been at least one rapid failure of new ones on the 300 that have been posted on this site. The guy was miles from anywhere with his 4x4 when the new damper with only a handfull of hours came apart and left him stranded.Got quoted $175 for rebuilding a crank pulley. Doesn't look as though I have much choice since I can't find a new one anywhere. Not sure of the dampers for the 170 or 200 will fit a 250. Weird that there aren't any new dampers out there.

IMO $175 for a dependable rebuild of such a critical component is worth every $.

jaymac2012

Active member

So I have read that there are two different 6 cylinder engine mounts for the 65 mustang: one for the coupe and one for the convertible (lowers the engine by a half an inch). How do I identify this for my convertible? I've read that that it only affects the exhaust system. That doesn't really matter to me because I'm probably going to get a custom exhaust for it. Any idea how to find the right brackets? And does it really matter in the long run.

TrickSix

Famous Member

I've had a '66 six-cylinder convertible for a while now. Just put new motor mounts in it (the second time) a few years ago. I have never heard of any motor mount differences between the coupes and convertibles. I can't imagine why the convertible engine has to be just a half inch lower than the coupe's. There are differences with the V8 brackets and the later 250 six brackets. The convertibles do have a chassis brace under the car the coupes don't have. If your exhaust system is sagging there could be an interference problem then. But if you're depending on a single half inch of engine height to determine whether the exhaust system fits or not there's bound to be trouble ahead. Call me skeptical.So I have read that there are two different 6 cylinder engine mounts for the 65 mustang: one for the coupe and one for the convertible (lowers the engine by a half an inch). How do I identify this for my convertible? I've read that that it only affects the exhaust system. That doesn't really matter to me because I'm probably going to get a custom exhaust for it. Any idea how to find the right brackets? And does it really matter in the long run.

There are 2 different mounts for the 1965 I6 Mustangs: the one for the left side differs from the one for the right side. There are differences in 250 convertible engine mounts in some of the later cars. If I remember correctly, the 1969 and 1970 250 isolators - the parts that attach to the engine - were different for the convertible and are no longer available, other than in used form.

jaymac2012

Active member

My dad put this 250 in my mom's 66 coupe, so I'm unsure of how it fits in my vert. Guess I'll solve that problem when it pops up. I did see a listing for a functioning 200 for $600 and I was super tempted... This 250 is a bit of oddity.

Yes, that alternator bracket should be off a 250 but if you post the part number we can tell for sure. If you look at the side with the adjuster bolted to it, there should be four holes for an AC compressor.

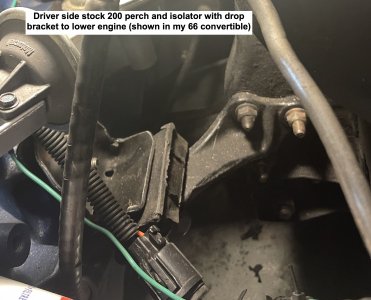

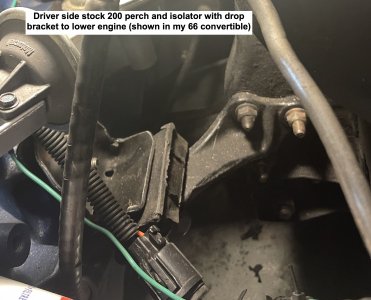

The mounts used to fit the 250 in the 66 should also work to fit it in the 65. If you don't still have them, you can look at my approach, which has worked perfectly since I installed the 250 in my 66 convertible back in 2014My dad put this 250 in my mom's 66 coupe, so I'm unsure of how it fits in my vert. Guess I'll solve that problem when it pops up. I did see a listing for a functioning 200 for $600 and I was super tempted... This 250 is a bit of oddity.

Last edited:

jaymac2012

Active member

I paid $400 to refurbish the head and $500 to bore and hone the block with new .030 pistons, so I feel like I'm kind of locked into the 250. Lol.If you sell your 250 let us know. What is your location?

I'm in St Louis.

jaymac2012

Active member

So here's what my dad did almost 30 years ago. I'm not even sure where these motor mounts come from (vehicle) , but they work if you turn them about 30 degrees and use only two holes. Here's what they look like. Left is placed in position with all three holes lined up. On the right the bracket is placed with two of the holes lining up. It works, but I'd love to use the correct engine mount.

The body brackets stuff seem like a pretty dark market. Not a lot of intel on line and most mustang retail websites don't even mention them. Not to mention most guys go from a I6 to a V8, not the other way around. I'm kind of expecting an uphill slog on this.

The body brackets stuff seem like a pretty dark market. Not a lot of intel on line and most mustang retail websites don't even mention them. Not to mention most guys go from a I6 to a V8, not the other way around. I'm kind of expecting an uphill slog on this.

Attachments

OK understood makes sense to keep going with the 250 install. Definitely some work and frustration involved but the results will be worth it.I paid $400 to refurbish the head and $500 to bore and hone the block with new .030 pistons, so I feel like I'm kind of locked into the 250. Lol.

I'm in St Louis.

Those appear to be the perches (attach to the frame) and isolators (attach to the engine and the perch) the factory used for the 200 engine. I used the same things for mine but they're in the normal positions. I confess I don't see how the one on the left in your photo connects to the engine. The angle of the isolator is all wrong and it's far too low. Is there another piece that connects that to the engine?So here's what my dad did almost 30 years ago. I'm not even sure where these motor mounts come from (vehicle) , but they work if you turn them about 30 degrees and use only two holes. Here's what they look like. Left is placed in position with all three holes lined up. On the right the bracket is placed with two of the holes lining up. It works, but I'd love to use the correct engine mount.

As an aside, I will confess that I'm a bit odd in that I removed a V8 and installed the 250 I6. It was an interesting learning experience. I'd done a website pertaining to some of the challenges I had. It's on an ISP that I have not used in a few years so I don't know how long it will stay there, but you can peruse it at your leisure.

Last edited:

jaymac2012

Active member

These were the engine perches that my dad scrounged up in the 90s when you couldn't order parts online. You had to go to the junkyard and find something that works. Not to mention, our 66 mustang was a car. We drove it all over the place, so he just got it running so we had an extra car. We were poor growing up. These perches are not the right perches for the mustang. They probably for a different ford that has a different bolt hole orientation. They were a compromise to get the new engine in. The one on the left is in the correct position according to the bolt holes in the body. But it will not mount to the engine. It will only mount to the engine if you use two bolts, like in the right one. I guess my question is this: do the i6 200 engines perches bolt up to an i6 250?Those appear to be the perches (attach to the frame) and isolators (attach to the engine and the perch) the factory used for the 200 engine. I used the same things for mine but they're in the normal positions. I confess I don't see how the one on the left in your photo connects to the engine. The angle of the isolator is all wrong and it's far too low. Is there another piece that connects that to the engine?

As an aside, I will confess that I'm a bit odd in that I removed a V8 and installed the 250 I6. It was an interesting learning experience. I'd done a website pertaining to some of the challenges I had. It's on an ISP that I have not used in a few years so I don't know how long it will stay there, but you can peruse it at your leisure.

To answer your last question first, yes. The 200 isolators will bolt to the 250. The perches will also work but if you use the 200 isolators, the engine will be too high to close the stock hood. That's why I modified my setup.

The perches you have could be from a Fairlane or Falcon. If you can find a casting number on them I can look it up.

I think I bought my perches from eBay. I MAY have another set of perches here but will have to hunt. I will PM you if I find anything.

The perches you have could be from a Fairlane or Falcon. If you can find a casting number on them I can look it up.

I think I bought my perches from eBay. I MAY have another set of perches here but will have to hunt. I will PM you if I find anything.

Similar threads

- Replies

- 1

- Views

- 169

- Replies

- 6

- Views

- 576

- Replies

- 9

- Views

- 873

- Replies

- 16

- Views

- 3K