jaymac2012

Active member

Well, shit. The drop brackets sound like something I would need to fabricate. I think I've seen a few examples on this site. Thanks.

I don't have a small6, so can contribute nothing to the details. But I'd say for you not to toss the baby with the bathwater at this point. The perches your dad fabricated are plenty stout for the job. The car was used with them without issue. Yes finding "correct" parts is always desirable, just don't let that cause you to scrap everything that's already there, when that could potentially become an acceptable foundation for reuse with the necessary modifications.Well, shit. The drop brackets sound like something I would need to fabricate. I think I've seen a few examples on this site. Thanks.

No, there are only general guidelines. I got my handbook and read it while I was working to adapt the 250. The handbook recommends use of Maverick engine mounts, which I found to be very scarce. Worse, they appeared to me to require some significant changes to the Mustang to make them work, so that suggestion did not seem practical. In any case, the handbook is out of print and not available.Aren't there detailed instructions on what parts to use to get it done in the Handbook?

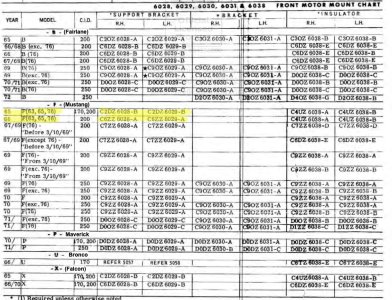

Ok thanks for the attachments.Following up - I found the perches I have and they look similar to those you have. The holes where the unit attaches to the frame of the car, like yours, don't match the ones on my 66. They have C7Z casting numbers, indicating that they are for a 1967 car, but the numbers don't appear in my reference document. So I'm puzzled. A browser search suggests that the part numbers I have (C7ZA-6061-A for the driver side and C7ZA-6037-A for the passenger side) are for a 1967 Mustang with the 200 I6 engine. I don't know what to believe about them. Sorry.

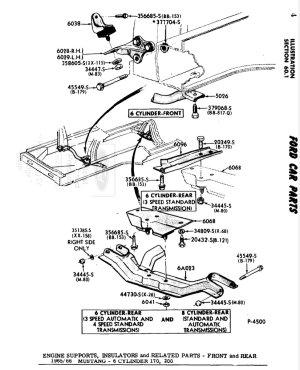

Adding additional confusion by posting some grabs from the Master Parts and Accessories Catalog

View attachment 24546

View attachment 24547

This is apparently quite frustrating regarding brackets and associated items. It seems like you would practically have to build some yourself or use the method developed by Mr. Ha which looks like a good solution.Ok thanks for the attachments.

Funny you should mention how stout they were, because you are right. They were stouter than the engine mounts on my 302. The left side was broken for years and I never knew it until I lifted the engine and the left one fell out on the floor!I don't have a small6, so can contribute nothing to the details. But I'd say for you not to toss the baby with the bathwater at this point. The perches your dad fabricated are plenty stout for the job. The car was used with them without issue. Yes finding "correct" parts is always desirable, just don't let that cause you to scrap everything that's already there, when that could potentially become an acceptable foundation for reuse with the necessary modifications.

I have a 67 vert with a stock small log headed 200 . Has a number of bolt on power adders.Okay. I don't really need either of those things. It's a convertible. I'll have to look for a stock one. I'm just wondering if you can even find stock stuff anymore that's not pitted or abused. Found one on eBay listed as stock but I don't necessarily trust eBay implicitly. Maybe I should keep the current cam so that I can drive pretty well at freeway speeds. I remember that it was really good at that.

My dad always thought this was a boat motor. Wonder if that could be true with this cam.

Stay away from Jeff Jones in Ca. He's a dishonest thief. Sold me an engine that had brazed crack in the block that was painted over. The block blew out within 4 months of delivery. Said he would replace, but did not follow thru. Oh, the head was stitched at a crack and failed too. Buyer beware.I have a 67 vert with a stock small log headed 200 . Has a number of bolt on power adders.

Your car so build it like you want it . After the last 6 years running a 2300 Sniper & Hyper Spark dist no way I'd change that cam . I'd search & find a good head that has been milled some with possibley some porting work .. you say you don't need the power or speed but i like the fact that if I choose I can easiley pass most interstate traffic unless somebody is standing on it . After I installed the Paxton 2 years ago I probaly can pass the people who are standing on their cars on the interstate . These small 6's are better than most people give them credit for .

Check on the Vintage 6 Mustang facebook site . Find Jeff Jones he does a lot of small 6 Ford work ,modified heads & eng builds. He's somewhere in California. He can probaly hook you up .

While your there check out the engines in Aron Cox & Danny Stucker's Mustang's

First thing bad i have heard about Him . But things like this are allways good to know. ThanksStay away from Jeff Jones in Ca. He's a dishonest thief. Sold me an engine that had brazed crack in the block that was painted over. The block blew out within 4 months of delivery. Said he would replace, but did not follow thru. Oh, the head was stitched at a crack and failed too. Buyer beware.

Need 250 mounts for a 65 coupe.how much?Member here @CoupeBoy makes mounts to fit the 250 in 60's Mustang. Reach out to him.

He reached out to me through a PM and I've responded.

I do make mounts.

I'm not terribly fast

If you need some let me know, but also let me know what you are working on as far as the vehicle and when you need them.

View attachment 25606

I need 250 mounts for a 65 mustang coupe.please reach back to meHe reached out to me through a PM and I've responded.

I do make mounts.

I'm not terribly fast

If you need some let me know, but also let me know what you are working on as far as the vehicle and when you need them.

View attachment 25606

Where are you located?So it looks like the 200 is good to go. Cylinders are a little tapered up and down, but my guy is gonna bore it out to .030. Head was warped slightly but within spec. Gonna get that rebuilt and the block bored and honed.

Anybody need a 250?