Go to a library, and get this book if you can.

http://www.amazon.co.uk/Tuning-British-Leylands-Series-Engine/dp/0854297324

Tuning British Leyland's 'A' Series Engine Hardcover – Aug 1989

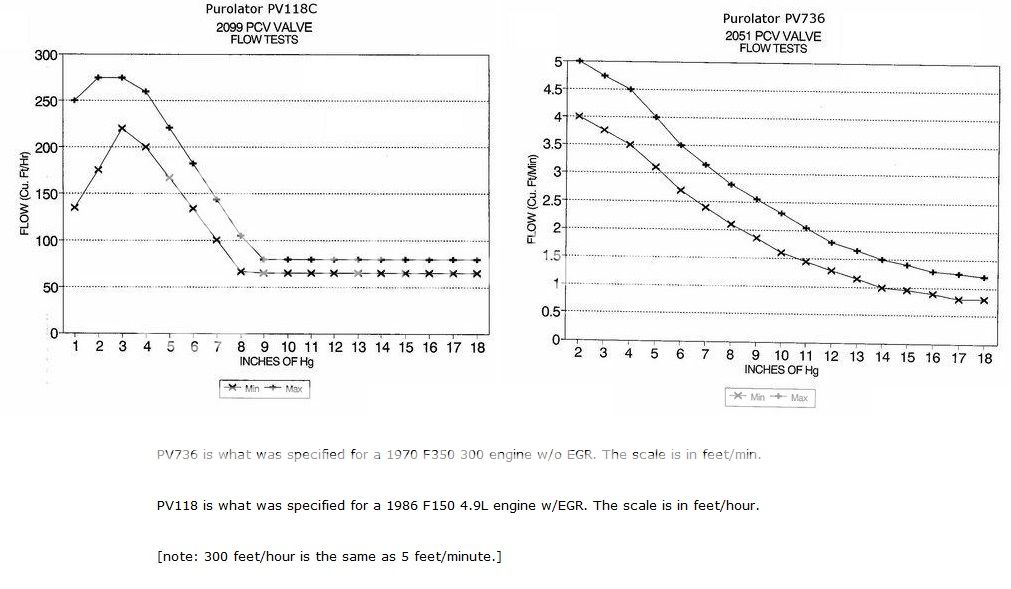

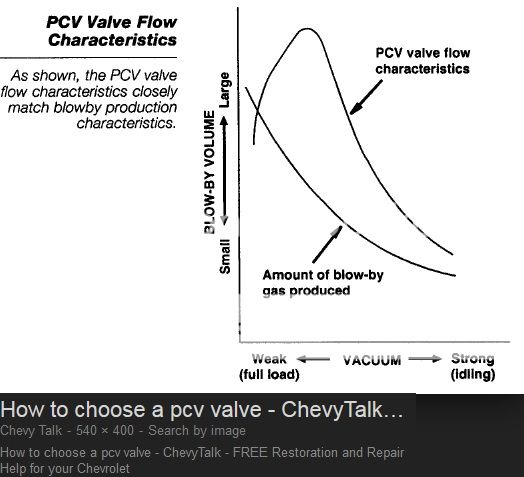

The problem with your high rpm air fuel ratio swing is blow by.

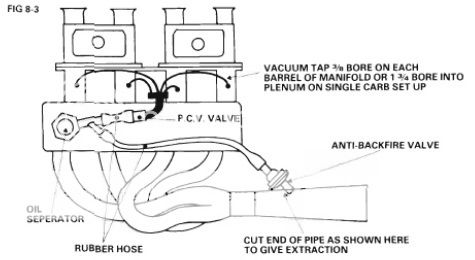

The way to fix it is to remove it by an evacusump system, two 5/8" PCV valves to the intake manifold from the rocker cover.

And then two anti back fire valves flowing in excess of 18 cfm each from the lower turbo manifold flange to a dedicated rocker cover catch can.

David Vizard described on in pages 398 and 399 of his second edition of modifying BMCs A series engine, and discussed Turbo applications specfically. Diagrams 15.2a, and 15.2 nail the sysyem down.

Its also covered in

How-to-Modify-Ford-s-o-h-c-Engines-David-Vizard

http://www.scribd.com/doc/26804743/How-to-Modify-Ford-s-o-h-c-Engines-David-Vizard#scribd

page 79 -85 Chapter 5 "Exhaust Manifold & Exhaust System"

and page 115

"This practice is relatively new and, as far as I know, it originated in the U.S.A.

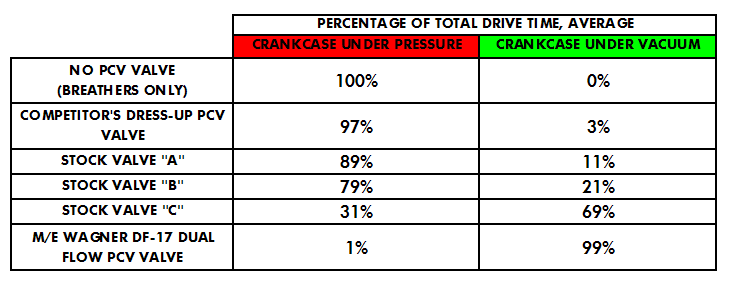

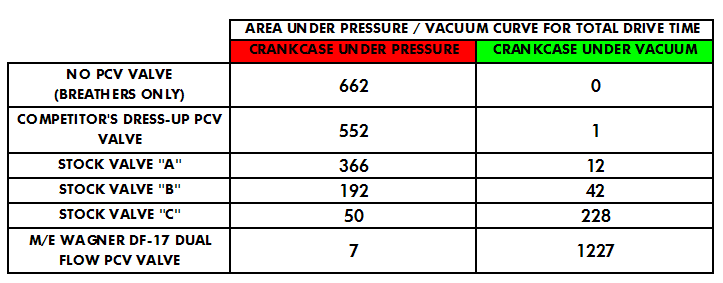

A Pressure-balanced lubrication system is a means of reducing the air pressure in the crankcase so the rings and valve seals have fewer tendencies to pass oil up into the combustion chambers. With air pressure reduced in the crankcase, the reverse tends to happen.

The higher pressure gases in the ports and combustion chambers tend to come down by the rings or seals and end up in the crankcase. Now at first this may seem to be the wrong way of doing things but it does have several advantages......"

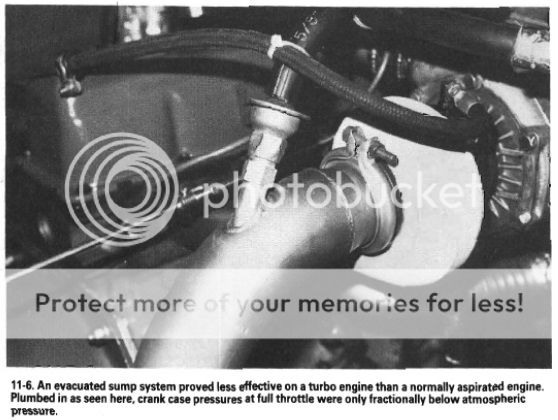

"......This brings us to crankcase ventilation. On very high-rpm turbocharged engines, ventilation of the crankcase becomes super-important. Unless there is space for plenty of air to move in and out of the crankcase, the engine is likely to blow an oil mist out, covering the engine’ compartment with oil. It will also drop oil on the track and your fellow competitors will not thank you for this"

Fig 8_3, page 115 with just one 18 cfm PCV.

In the A series 2ND Edition book, DV said that

blow by from valves and pistons collectively defines remaining engine life. An Evacusump system should pull 1.85 to 2.65 inches of Hg suction at operating temperature. When the figure drops below that, it only has 15 to 30 minutes more operation time at full load.

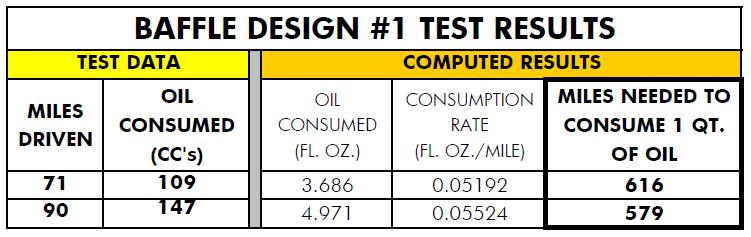

Fig from Page 135