No one likes the early twin throttle body F and E series stuff because it was 9 times out of 10 Speed Density. The exceptions were the 1996 OBDII's, and 1994 on Cali F's and E's. Those asside, they were SD systems. Seams like everyone likes hotwire MAF sensor bits, its so much easier, but the SD stuff sure is cheap, and you can down grade its fuel delivery specs easily to suit a 200 or 250 small six.

There never was more trucks sold than F150's. You can't hide a single throttle body and MAF sensor in a stock I6 air cleaner like you can with the Big Six 4.9 stuff.

If you want to go crazy, you can use

Method 3 to make up a tube intake log adapter like Peter Knott's 170 Roundbody Falcon's 280 hp cross over intake upper manifold.

Getting back to what you can do with a few tubes and some knowledge, Paul Knott is getting an E38 style 280 hp at as low as 6500 rpm from just 170 cubes in his 62XK Falcon.

See

http://www.fordsix.com/forum/viewtopic.php?t=70764

Its a blend of 4.9 EFI and Weber DCOE 45's. On Fordtruckfanatics.com,

johny89 is from Koekelare in Belgium. That place on innovation again...His F150 Big Six with CA 300 on LPG shows how the twin throttle body and EFI plenum gives space for everything including a supercharger.

http://www.fordtruckfanatics.com/forum/ ... hp?t=34150

------>

Replace the M90 where the Impco CA 300 air cleaner is.

Its a little like the

Army of Six "My mega squirt install" Mar 02, 2009 EFI 240 update.

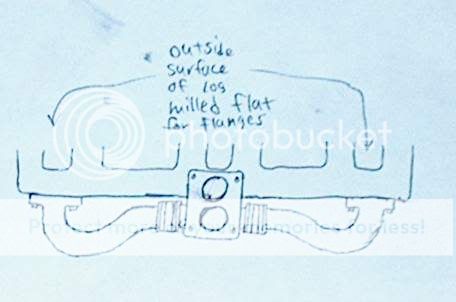

viewtopic.php?p=430533 In the instance of EFI-ing a little 200 log six, you add a custom new

lower part to the log, rather than a new custom

upper EFI part. You can use the stock 4.9 EFI upper as is. The Big Six has inlet 1 and Inlet 6 22.40 inches apart, while the Small six has differential pitching of the inlets, and inlet 1 and Inlet 6 on the log head are about 18.70 inches apart. So the outers need to be brought down to the log head spacings by about 1.85 inches (the difference 22.40-18.70, divided by two) each side on the outer inlets. Or you just do an Ak Miller

http://www.classicinlines.com/HA1.asp and add four pipes by braising, then perhaps two extra sidewinders to the outer welsh plugs on the log. The log intakes vary from 21.25 to 21.85" long, and a 22.4 inch spacing 4.9 EFI manifold would then fit with ease, each of the six pipes would then line up with the upper intake with the utmost simplicity.

A 50% drop in capacity from 300 cubes to 200 isn't a major,when you can control injector size and fuel pressure. SD EFI gets screwed up when the pulse timings are out of sequence, so you'll only have to run the stock 110 degree lob centers that the 240 and 300 268 degree cam did, and then fiddle with the fuel delivery pressure and/or injector sizes to suit.

http://www.ford-trucks.com/forums/10360 ... ers-8.html

For big 250 engines, you can go up on lobe center to 112, up on lift to about 500 thou, go up on cam intensity and thus up on duration to about 210 at 50 thou, and it should still run nice. For a 200, you'll have to stay back to 260 to 268 degrees at lash, and less than 205 deg at 50 thou. Stock 110 lobe centers should be okay. Lift gets risky over 450 thou without valve gear mods.

http://www.fordsix.com/forum/viewtopic. ... &view=next

You can go up in lift and duration, and change cam retard and advance as long as you don't hit the cam casting with the conrods.