I'm rebuilding my 64 1/2 mustang (engine overhaul, transmission rebuild, some body work). I sent the engine out to get some machine work done (0.030" over on the cylinders, put in hardened valve seats, etc.). My engine has the unique combination of hydraulic lifters AND mechanical lash adjusters on the rocker shaft - this setup is original to the engine, at least as long as I've had it (1991).

My concern: The mechanical adjuster screws are nearly bottomed out (see picture below). Most of them have a little adjustment room left, but not much. I'd rather be running with them set a little bit more in the middle of the thread range in case I need to made further adjustments. It seems like oversized pushrods would be helpful here, but finding those appears to be a bit challenging... even finding standard length pushrods wasn't super easy (I had to replace one during the rebuild).

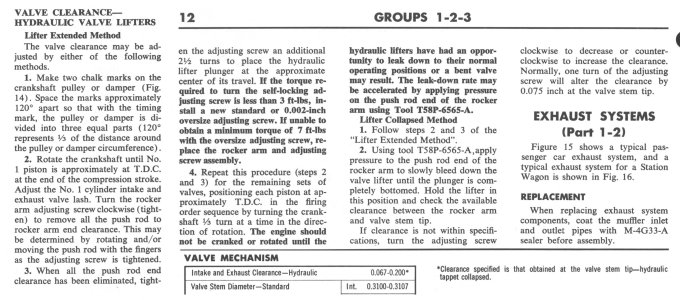

I've adjusted the lash by tightening the adjusters down to the point where there it was difficult to rotate the pushrods, and then went another 1/2-3/4 turn. This was done with the hydraulic lifters bled down (they're new and have never been pumped up yet), and with the engine cold. I haven't yet fired the engine after the rebuild.

Thoughts on this? Any ideas why I would be at the extreme end of the adjusters? I did go back to a few pictures before the rebuild, and it looks like they were in a similar position with the adjusters screwed most of the way in (though not quite as extreme as this picture shows here).

Any options out there for longer pushrods? Is this something to be concerned about?

Thanks,

Wes

My concern: The mechanical adjuster screws are nearly bottomed out (see picture below). Most of them have a little adjustment room left, but not much. I'd rather be running with them set a little bit more in the middle of the thread range in case I need to made further adjustments. It seems like oversized pushrods would be helpful here, but finding those appears to be a bit challenging... even finding standard length pushrods wasn't super easy (I had to replace one during the rebuild).

I've adjusted the lash by tightening the adjusters down to the point where there it was difficult to rotate the pushrods, and then went another 1/2-3/4 turn. This was done with the hydraulic lifters bled down (they're new and have never been pumped up yet), and with the engine cold. I haven't yet fired the engine after the rebuild.

Thoughts on this? Any ideas why I would be at the extreme end of the adjusters? I did go back to a few pictures before the rebuild, and it looks like they were in a similar position with the adjusters screwed most of the way in (though not quite as extreme as this picture shows here).

Any options out there for longer pushrods? Is this something to be concerned about?

Thanks,

Wes