twentyover

Well-known member

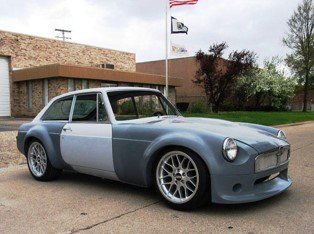

Am considering undertaking a 250 engine build using the 2,5 rods and 3332 pistons. The target car is an old English sportscar that came with a 2.9l engine that was overweight and oversize. And underpowered. The plan would be to make the swap keeping the body pretty much uncut so it could go backward if I ever lose my mind. A requirement is that the car have a manual transmission.

Trying to find a flywheel for a 250. Unlike the 200's, it seems these are unicorns. I understand they are the same diameter as 302 wheels- is the crank bolt pattern different, a different balance factor, or what? What makes them unique?

In a fever dream, if I follow thru with this plan and am unable to find a flywheel, I thought maybe start with an automatic flex plate, have an aluminum disc machined to the correct diameter, and cut so a steel clutch surface is installed. I've gotta cut down on the pizza before I go to bed

Trying to find a flywheel for a 250. Unlike the 200's, it seems these are unicorns. I understand they are the same diameter as 302 wheels- is the crank bolt pattern different, a different balance factor, or what? What makes them unique?

In a fever dream, if I follow thru with this plan and am unable to find a flywheel, I thought maybe start with an automatic flex plate, have an aluminum disc machined to the correct diameter, and cut so a steel clutch surface is installed. I've gotta cut down on the pizza before I go to bed