Oof thats a lot of money all at once haha. Hopefully it doesn't need much. They looked decent and don't really have a ridge on them. But that seems like the logical way to approach it. Thanks man. Now how much will that cam change if I use the 1.65 yella terra rolllers? Turbo cams are custom grinds, right? The cam too will be dependent on the transmission i run too, right? B/c drag 200 above brought up a good point.The next step is to get the short block apart and have the machine shop clean and figure out how much the cylinders need to be bored to clean them up.

This will tell you what size piston you will need.

Have the block deck surface machined just enough to clean the surface for good head gasket sealing.

Then have the block deck height measured so you will know what the piston CH needs to be.

Have the crankshaft checked for cracks.

At the same time start on the cylinder head.

The finished cylinder heads combustion chamber volume will determine the piston dish volume to get the correct compression ratio.

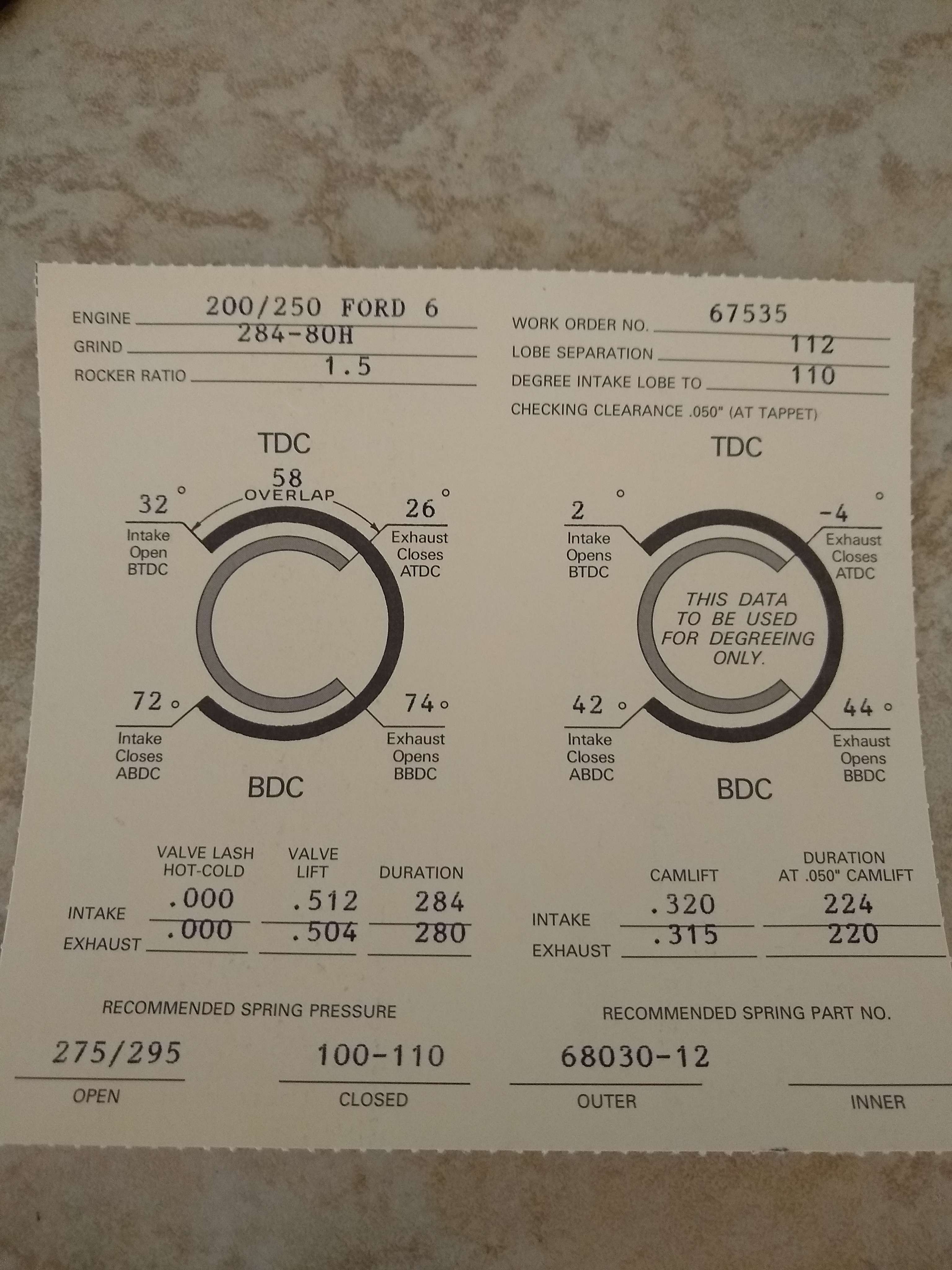

You will need to decide on a camshaft which will determine what valve spring to install on the head.

Here is the last turbo cam Schneider ground for a 200 six.

It will have a power band right about where you need to be.

For the turbo build on 14psi, what kind of compressions should I be aiming for? 8.5?