Hey all, finally had time to pull my motor and and start the process of a full rebuild. Here’s the current list of parts…

Aluminum head serial #026

Yella Terra 1:65 roller rockers

Double timing chain

Holley 2300 sniper

Holley hyper spark distributor and coil pack

Schneider cams 262-70h cam

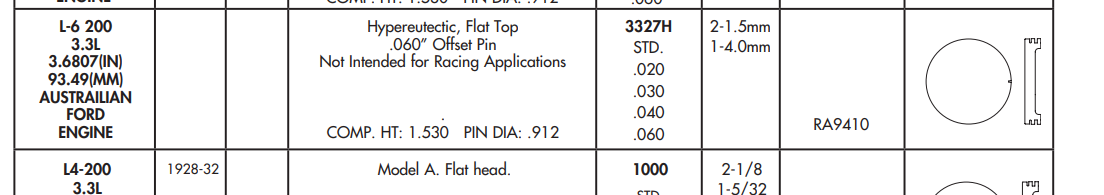

I’m going with flat top pistons but don’t know if I need to bore the block yet. T5 conversion. A bunch of other miscellaneous parts. I do have a couple questions though.

Should I upgrade the radiator from factory? The original one looks to be in good shape and doesn’t have much crud in it. Do they flow enough for a mild build?

The alternator that’s in the car doesn’t have any tags on it except “tested to 70 amps”. It is not a single wire alternator. Will I have issues running the Holley components with this? I’m sure I’ll I’ll have a lot more questions as I continue on. Calling this week to get in to the machine shop for the block work. Decking, cam bearings etc. It has been about 5 years in the making for parts acquisition and time to do it but I’m glad it’s finally started!

Seen your post about the radiator. I have a 67 Mustang vert 200/c4 . I run a small log head with a 2300 Sniper & Hyperspark . I installed a Paxton on it about .2 years ago . Before the Paxton install i ran a new copper & brass oem type radiator and everything was fine .

During the Paxton install i put a brand new alumn Radiator in, a new flow cooler water pump along with a flex blade fan .

Have to really keep an eye on it now . In slow or stopped traffic it will heat up sometimes badley . Planning on installing pretty much every thing on my eng that you listed other than the rebuild . Been about a 6 year acculation of parts .When I do I plan on going back to the oem style radiator .

You put your timeing #'s in the handheld try 24 degrees for your idle . My motor did'nt like the factory 12 degrees at all for idle setting.

Put 24 in & it idles smooth now .

You will like that 2300 if you get it sorted out . Adds a good bit of power . For what it's worth get an intank efi fuel pump . The inline pumps that.come with the Sniper kits are a problem waiting to happen .

Another suggestion is to install an electronic fuel pressure gauge inside where you can monitor your fuel pressure , a pressure gauge under the hood is pretty useless .

Another for what it's worth , be on the lookout out for a Paxton set up for your 200 ,that thing is killer paired up with a 2300 Sniper . My vert runs like it has a v8 in now . Even pushing everything thru that small log head .

www.summitracing.com