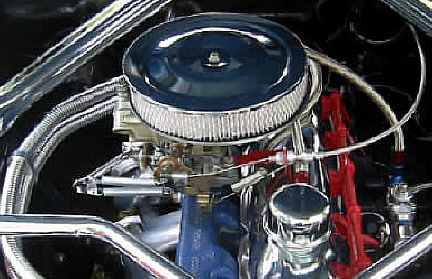

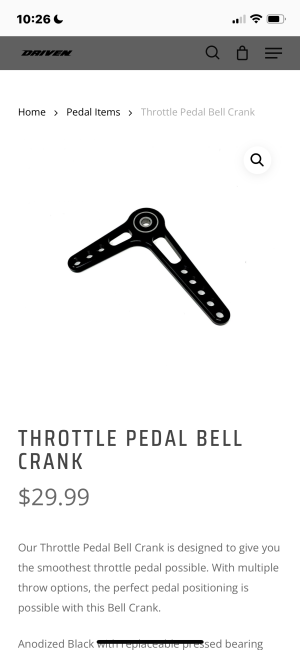

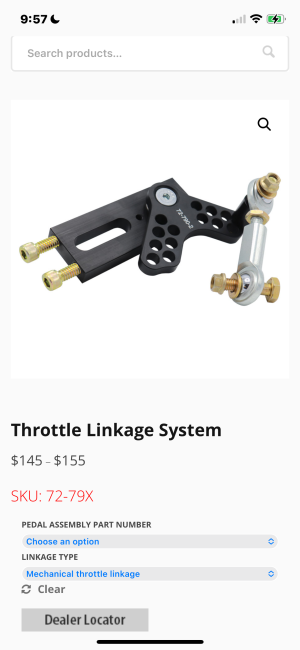

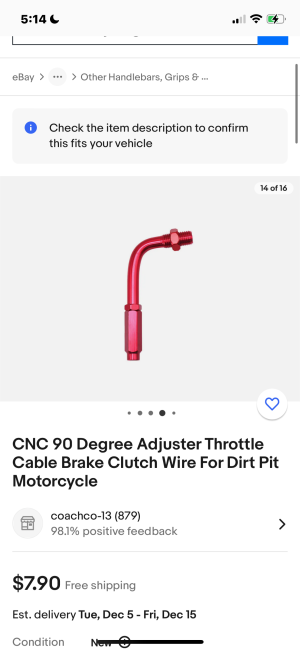

I want to install a Weber 32/36 on my 1966 Bronco. Anyone put a Weber in their Early Bronco I6? If so, what did you do about gas pedal linkage? Currently I use a throttle cable to a single barrel 1904. And the videos I find online show Mustangs with a solid rod from the gas pedal assembly to the Weber's linkage (with some mods). Any help is appreciated. thx

Last edited: