OK, I might have found an additional PO issue that

may be causing my plugs to foul like crazy. I keep seeing engines with the PCV valve stuck into a hole at the firewall-end of the valve cover. My valve cover has no such hole. A box of take-offs was in my trunk when I got the car. Inside that box is a tube that I'm pretty sure was a crankcase vent downtube. The PCV hose running from the carburetor spacer routes to something (a PCV valve, I guess) stuck

hard into a hole in the block at the forward, driver-side. I'm thinking that that was where a PO removed the downtube. Since it's not at the top of the valve cover, and it might not be a PCV valve, for that matter, could it be sucking misty oil into the intake? Regardless, given every other 200-6 PCV seems to be stuck in the valve cover, surely this isn't where it goes.

But, hey, I might be all wet.

I included part of the distributor so you can tell for sure where it is:

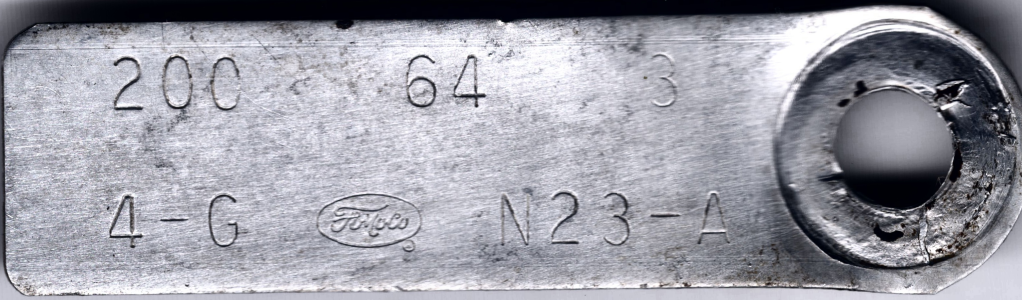

View attachment 24050