Evening All

I'm heading down to the machinist tomorrow to come up with a gameplan on my 262 build. I was hoping to entice some advice from you all on a few subjects. The shop has checked the block, head and crank and all are good to continue. The block has been shotpeened and now we need to work out the details. the cylinders will need bored, not sure how much yet with new custom pistons. we are installing new guides, seats and more than likely oversized valves in the head. I will be using the Clifford dual Webber intake and already have the Clifford header installed last summer. I am going to modify the header into a 2/4 split over the 3/3 with dual 2 inch glasspacks out the rear ,as the old cast exhaust manifold was done this way in the 80's and i love the exhaust note. First question, what other headwork or what valve sizes do you recommend? This is a driver that will see a little pickup camper use, show and shines and lots of happy miles on backroads and gravel roads. I will also be completing a t5 trans swap with 410 rear gears .This is not a race truck. Most likely it will never see 4000 rpm. My thoughts are if were here why not do what we can to help things. I have read that high lift rockers on the exhaust side work well with breathing. Ideas on where to locate said rockers?

Second question, compression ratio. I understand that if a modern thicker head gasket is used that the block needs to be machined to correct for the difference. I am already running a duraspark 2 distributor, 8.8 plug wires MSD blaster coil and MSD 6al box. What compression ratio can I safely run with this ignition setup on 87=89 octane? I always run 91 octane but want to be safe incase I'm in a location where that isn't an option. I think factory was between 8-1 to 8.5-1. Would 9-1 be unreasonable? Again, while were here why not.

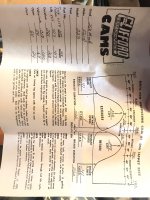

And lastly and maybe most important, camshaft regrind. I am thinking Schneider cams or Delta for the regrind. Are these acceptable choices . And knowing this isn't a race motor , but while were here, do you advise a stock regrind or is there a little room for improvement? I'm asking for detailed numbers and information to run by the builder and cam shop. My thoughts here is to take advantage of the headwork and intake \exhaust improvements. Planning to send the lifters for resurfacing at the same time. I simply am ignorant on this matter and though I need to trust my machine shop, I can still verify where I'm being lead.

If there are further details I need to know about that are uncommon or easily looked over PLEASE let me know. I take the advice of those in this group to heart. Thank you for reading and your opinions in advance.

Rick

I'm heading down to the machinist tomorrow to come up with a gameplan on my 262 build. I was hoping to entice some advice from you all on a few subjects. The shop has checked the block, head and crank and all are good to continue. The block has been shotpeened and now we need to work out the details. the cylinders will need bored, not sure how much yet with new custom pistons. we are installing new guides, seats and more than likely oversized valves in the head. I will be using the Clifford dual Webber intake and already have the Clifford header installed last summer. I am going to modify the header into a 2/4 split over the 3/3 with dual 2 inch glasspacks out the rear ,as the old cast exhaust manifold was done this way in the 80's and i love the exhaust note. First question, what other headwork or what valve sizes do you recommend? This is a driver that will see a little pickup camper use, show and shines and lots of happy miles on backroads and gravel roads. I will also be completing a t5 trans swap with 410 rear gears .This is not a race truck. Most likely it will never see 4000 rpm. My thoughts are if were here why not do what we can to help things. I have read that high lift rockers on the exhaust side work well with breathing. Ideas on where to locate said rockers?

Second question, compression ratio. I understand that if a modern thicker head gasket is used that the block needs to be machined to correct for the difference. I am already running a duraspark 2 distributor, 8.8 plug wires MSD blaster coil and MSD 6al box. What compression ratio can I safely run with this ignition setup on 87=89 octane? I always run 91 octane but want to be safe incase I'm in a location where that isn't an option. I think factory was between 8-1 to 8.5-1. Would 9-1 be unreasonable? Again, while were here why not.

And lastly and maybe most important, camshaft regrind. I am thinking Schneider cams or Delta for the regrind. Are these acceptable choices . And knowing this isn't a race motor , but while were here, do you advise a stock regrind or is there a little room for improvement? I'm asking for detailed numbers and information to run by the builder and cam shop. My thoughts here is to take advantage of the headwork and intake \exhaust improvements. Planning to send the lifters for resurfacing at the same time. I simply am ignorant on this matter and though I need to trust my machine shop, I can still verify where I'm being lead.

If there are further details I need to know about that are uncommon or easily looked over PLEASE let me know. I take the advice of those in this group to heart. Thank you for reading and your opinions in advance.

Rick