shreqshack

Well-known member

Thanks guys! I am awaiting my Toyota FIPG sealant to arrive in the mail. In the mean time, I am trying to line up all details... Nobody wants to do this twice....thanks for all your help.

1.) Yes...I am using the Fel-Pro neoprene...sorry for not specifying from the start.

2.) The consensus is to put the butting ends at 4 and 10 oclock with the ends sticking out about 1/4" with a dab of Toyota FIPG.

What is a dab? when someone says dab to me....I am prone to use too much (more is better?).

3.) I have a question about putting oil or grease on the neoprene seal before inserting it.

--WSA111 suggested - "applying a liberal amount of lube to prevent a dry start."

I have read forums or viewed videos of people putting motor oil on the neoprene seal before inserting it? I read one recommendation to ""put grease on the lip or inside face of the seal that will rub on the crankshaft to keep the neoprene from burning up when you first crank the engine."" I was also wondering whether I need to be careful about how much oil or grease I put on the neoprene seal if I want the a "dab" of FIPG sealer on the ends to do its job....or am I over thinking this? Any thoughts on this?

---- It will be several weeks before I get all the parts back on the car...maybe grease would be better than oil for preventing a dry start? What type of grease/lube would you suggest?

4.) As Bubba suggested...I loosened several caps and used a pry bar to get the camshaft to move down a bit...I didn't actually see it move but I think it is loosened up enough to get the seal to slide in fairly easily.

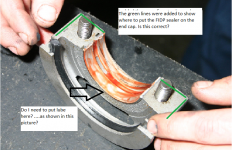

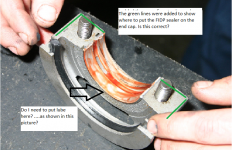

5.) Related to WSA111 and Chad's posts: - Sealer where the rear main caps sits on the block....

QUOTE: "Make sure you also put a small amount of sealer on the edge where the rear main cap sits in the block on both sides, also put a very thin layer of sealant at the back of the rear main cap from the seal to the end of the main cap on both sides. That will prevent seepage past the machined surfaces where the rear main cap seat into the block."

Here is a picture I found on the internet...I added the green lines? Is that where the sealer goes? Do I need to add any other lube on this? A small thin line of sealer is all i need? I have a tendency to use too much

Thanks everyone!!!

1.) Yes...I am using the Fel-Pro neoprene...sorry for not specifying from the start.

2.) The consensus is to put the butting ends at 4 and 10 oclock with the ends sticking out about 1/4" with a dab of Toyota FIPG.

What is a dab? when someone says dab to me....I am prone to use too much (more is better?).

3.) I have a question about putting oil or grease on the neoprene seal before inserting it.

--WSA111 suggested - "applying a liberal amount of lube to prevent a dry start."

I have read forums or viewed videos of people putting motor oil on the neoprene seal before inserting it? I read one recommendation to ""put grease on the lip or inside face of the seal that will rub on the crankshaft to keep the neoprene from burning up when you first crank the engine."" I was also wondering whether I need to be careful about how much oil or grease I put on the neoprene seal if I want the a "dab" of FIPG sealer on the ends to do its job....or am I over thinking this? Any thoughts on this?

---- It will be several weeks before I get all the parts back on the car...maybe grease would be better than oil for preventing a dry start? What type of grease/lube would you suggest?

4.) As Bubba suggested...I loosened several caps and used a pry bar to get the camshaft to move down a bit...I didn't actually see it move but I think it is loosened up enough to get the seal to slide in fairly easily.

5.) Related to WSA111 and Chad's posts: - Sealer where the rear main caps sits on the block....

QUOTE: "Make sure you also put a small amount of sealer on the edge where the rear main cap sits in the block on both sides, also put a very thin layer of sealant at the back of the rear main cap from the seal to the end of the main cap on both sides. That will prevent seepage past the machined surfaces where the rear main cap seat into the block."

Here is a picture I found on the internet...I added the green lines? Is that where the sealer goes? Do I need to add any other lube on this? A small thin line of sealer is all i need? I have a tendency to use too much

Thanks everyone!!!

Attachments

Last edited: